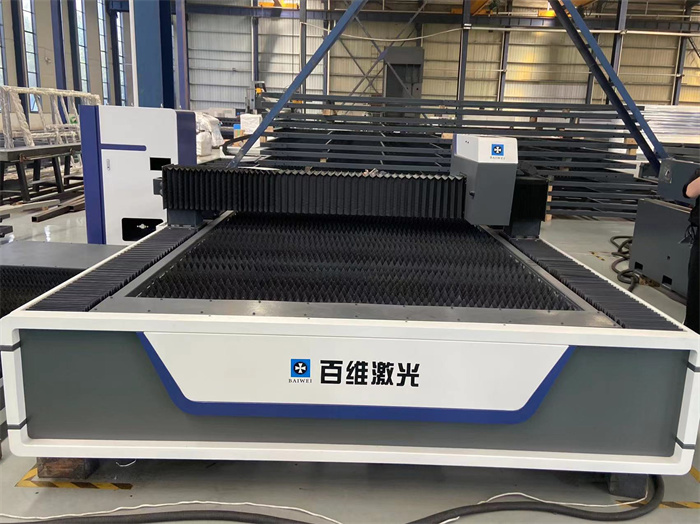

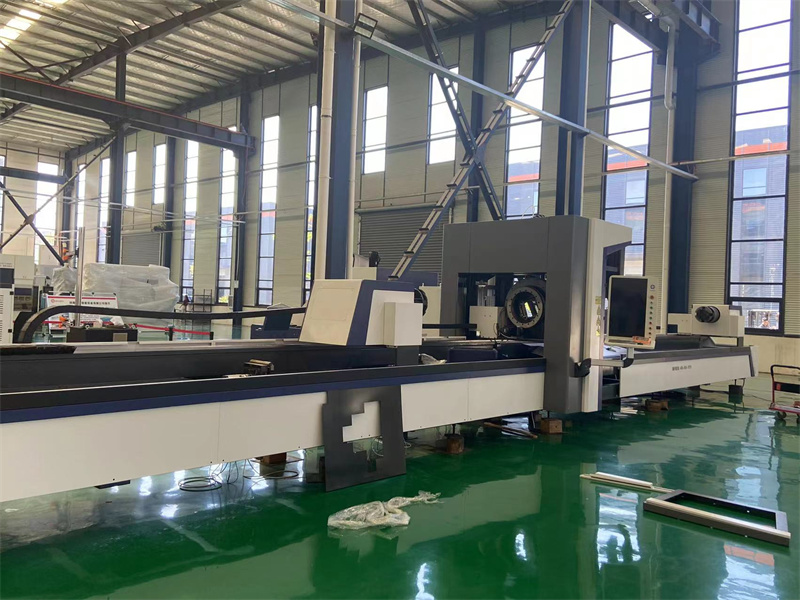

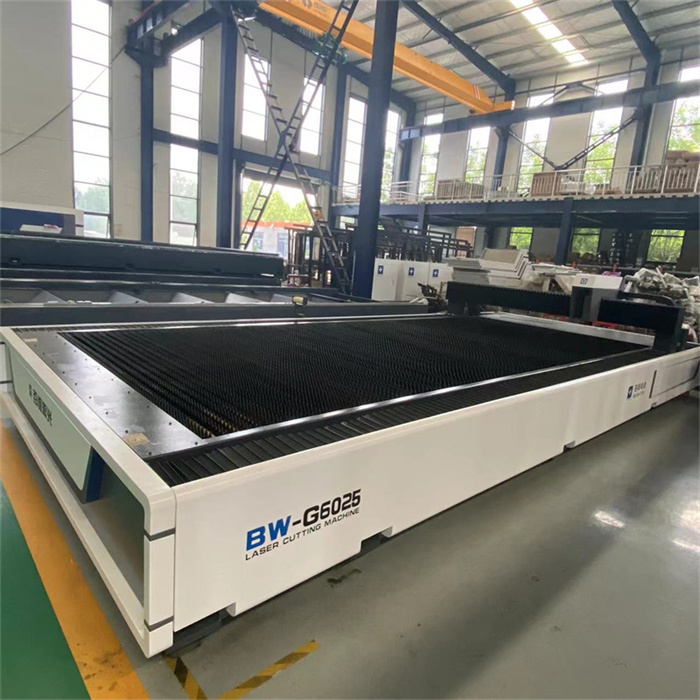

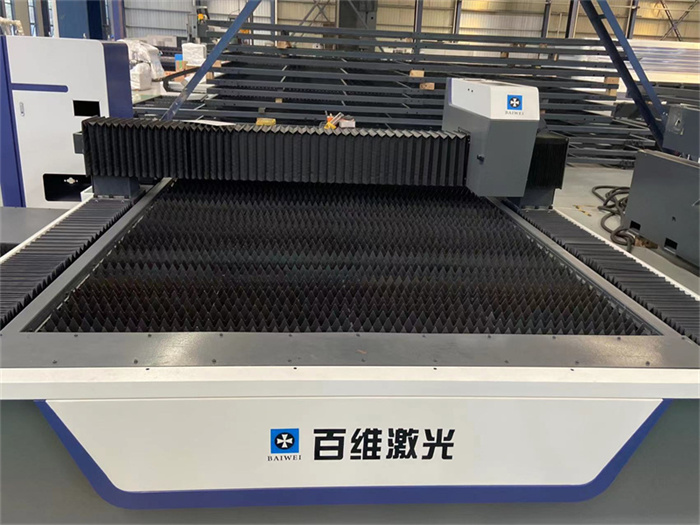

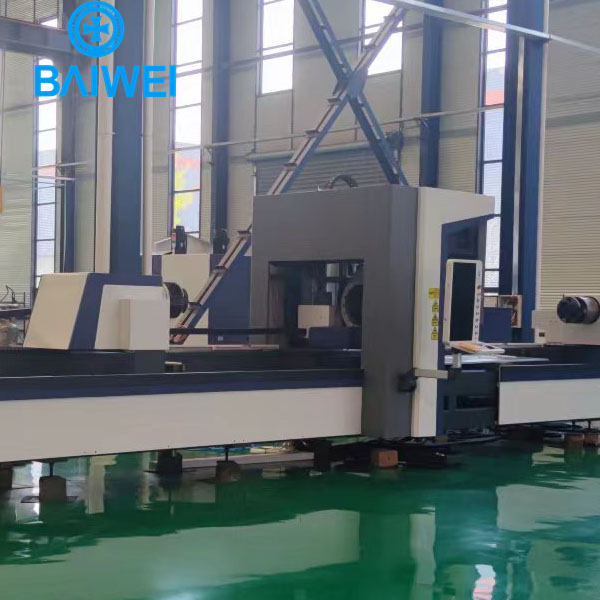

High-precision CNC stainless professional tube laser cutting machine

The professional tube laser cutting machine has a narrow slit and a small heat-affected area. The local deformation of the workpiece of the professional tube laser cutting machine is small, and there is no mechanical deformation.

Laser Type:Fiber Laser Source

Max. Output Power:500W/800W/1000W/1500W/2000W

Effective Pipe Cutting Diameter:¡Ü220MM

Effective Pipe Cutting Length:3000MM/6000MM

Workable Axis Positioning Accuracy:¡Ü¡À0.05MM

The fiber laser cutting machine uses the energy released when the laser beam irradiates the surface of the workpiece to melt and evaporate the workpiece, so as to achieve the purpose of cutting and engraving. There is no need for mold opening and cutting tools, and there is no stress on the product. It has the characteristics of high precision, fast cutting speed, not limited by cutting pattern, automatic typesetting, material saving, smooth cutting, and low processing cost. The fiber laser cutting machine system generally consists of a laser generator, (external) beam transmission components, a workbench (machine tool), a microcomputer numerical control cabinet, a cooler and a computer (hardware and software).