How to choose a good fiber laser cutting machine?

After years of development of Fiber laser cutting machines for various industries to improve the production efficiency of processing production, the application in various industries is becoming more widespread.

Fiber laser cutting machines use laser technology for processing and production, which is non-contact processing. Compared with traditional methods, they do not cause deformation and damage to the material, and the processing is fine and fast.

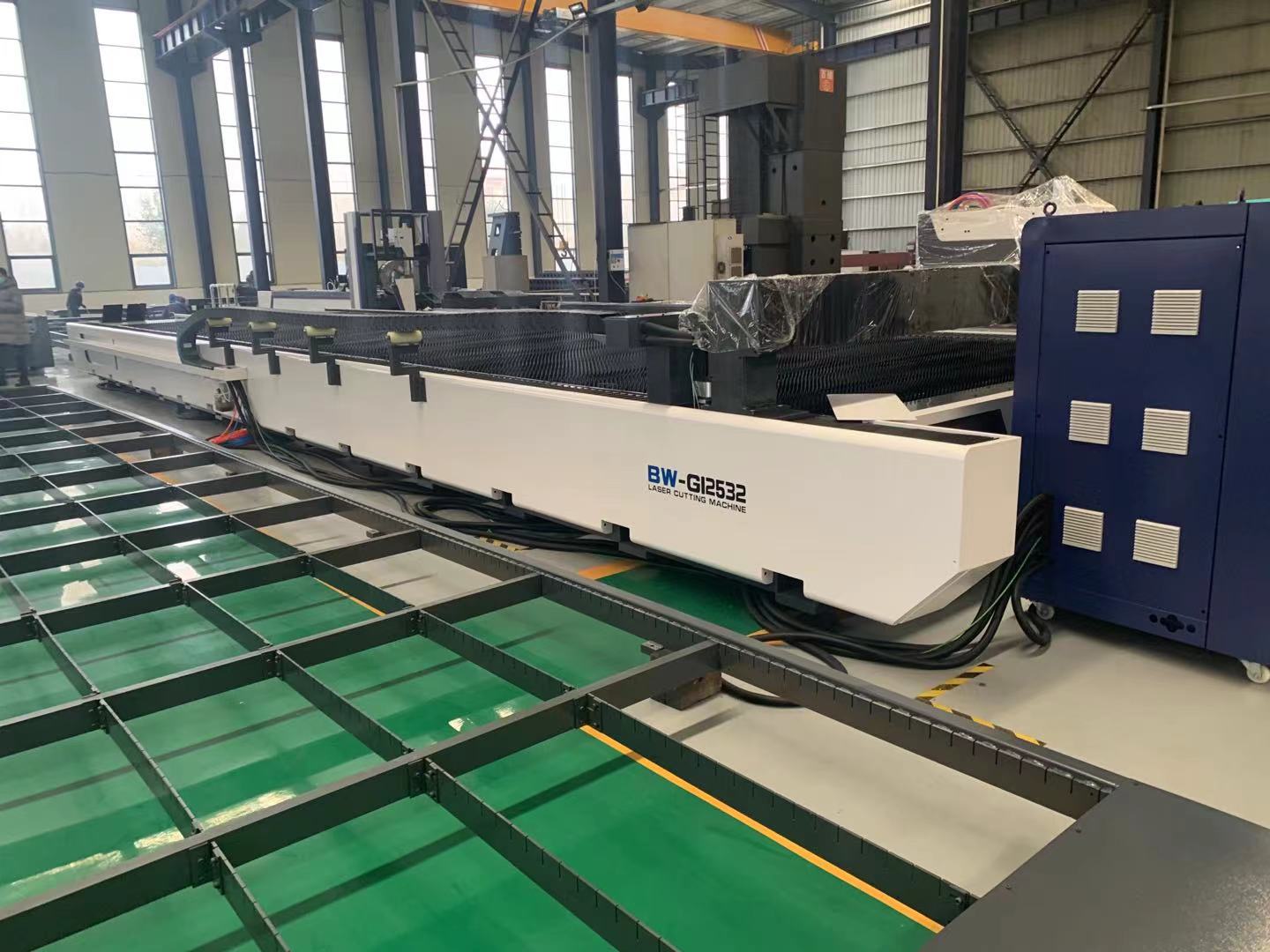

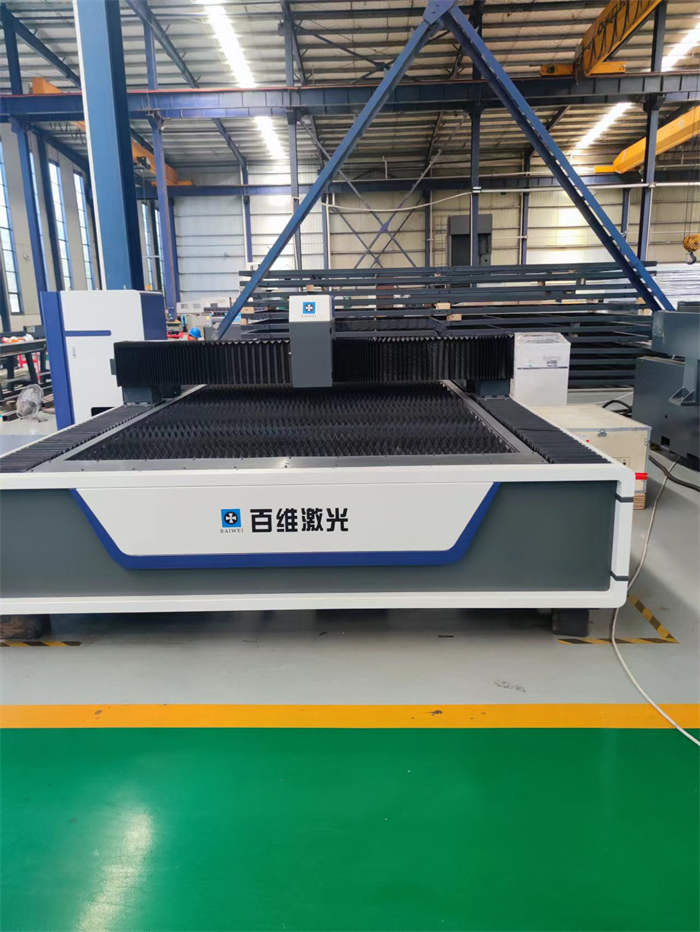

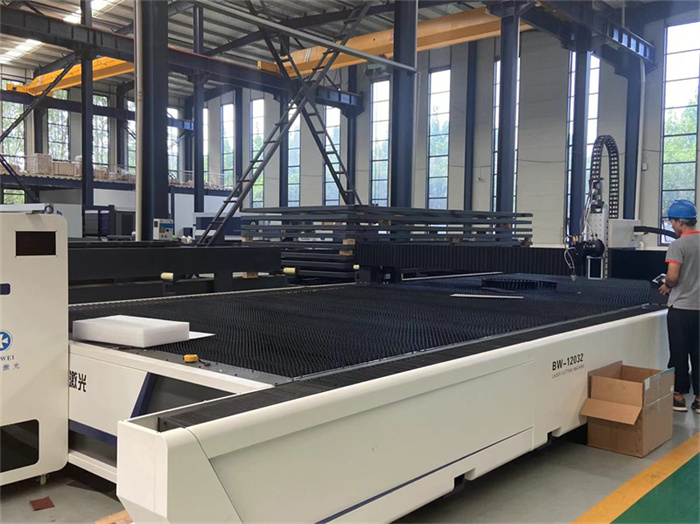

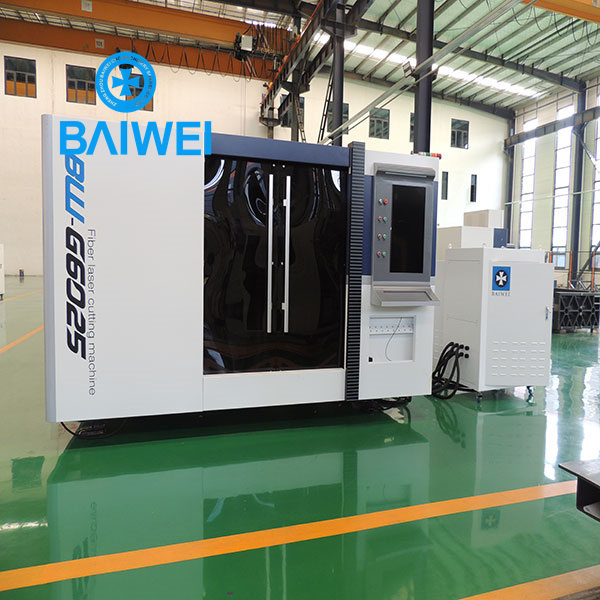

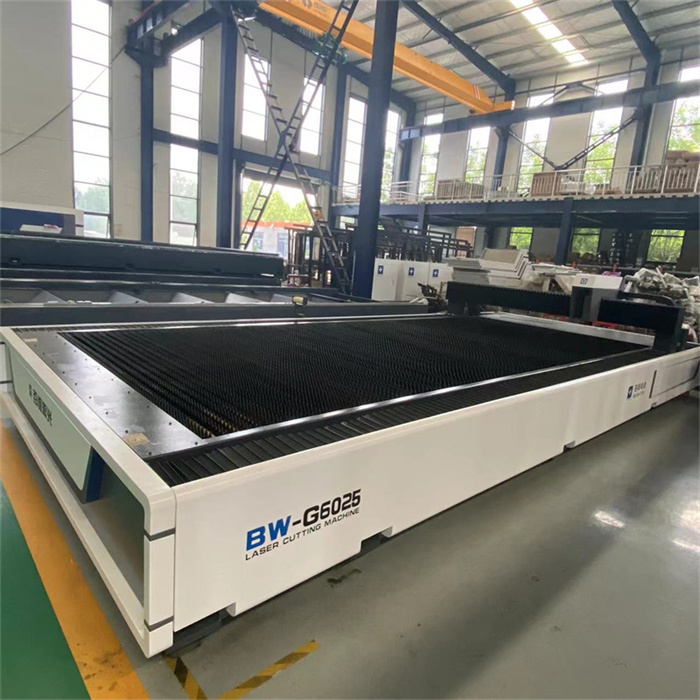

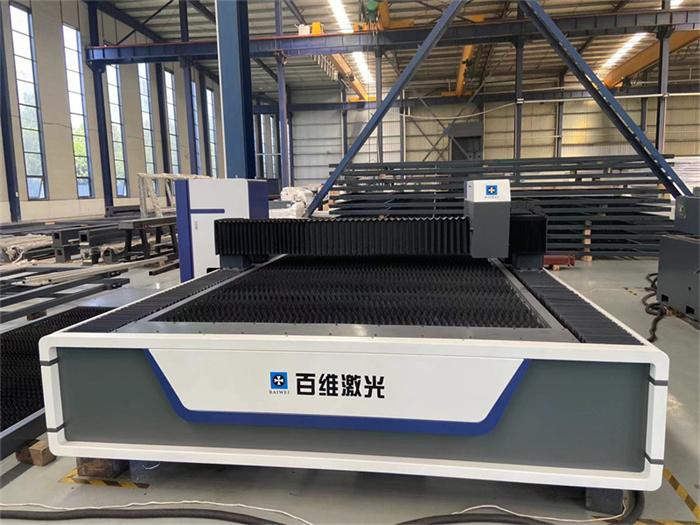

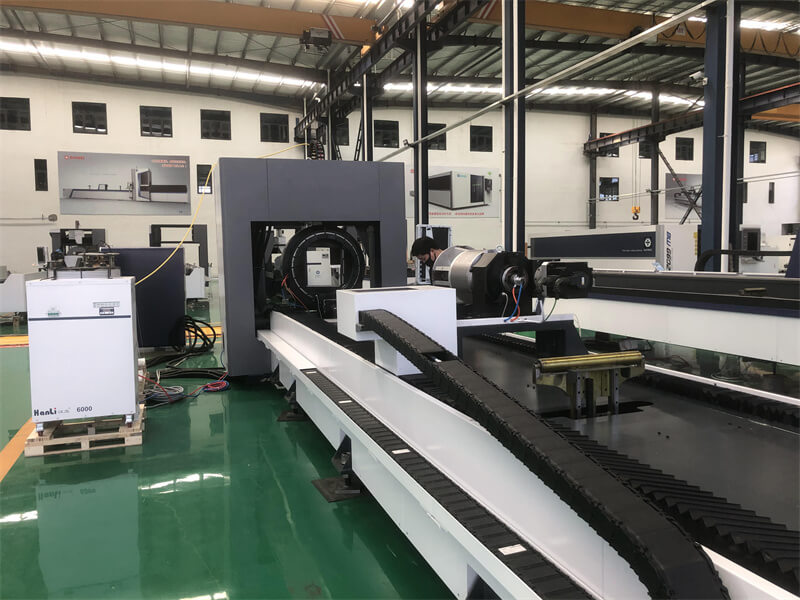

Name: Enclosed fiber laser machine

Model: BW-G6025-8kw

Power: 8000W

Laser source: Raycus / IPG / nLIGHT

Cutting Head: Precitec

Control system: Cypcut (China)

Servo motor : Panasonic / YASKAWA (Japan)

Reducer: Neugart / Shimpo

Gear and rack: APEX / YYC (Taiwan,China)

Guide rail : PMI / HIWIN (Taiwan,China)

Warranty time THREE YEARS

Working Area: 6000*2500mm

Cutting Thickness Max 30mm MS, Max 20mm SS,

Worktable Max Load: 2000kg

Weight of the Machine 5500 kg

Dimension 4400x2500x1800mm

Total electric power consumed : 80 kw/h

Machine structure: Dual drive

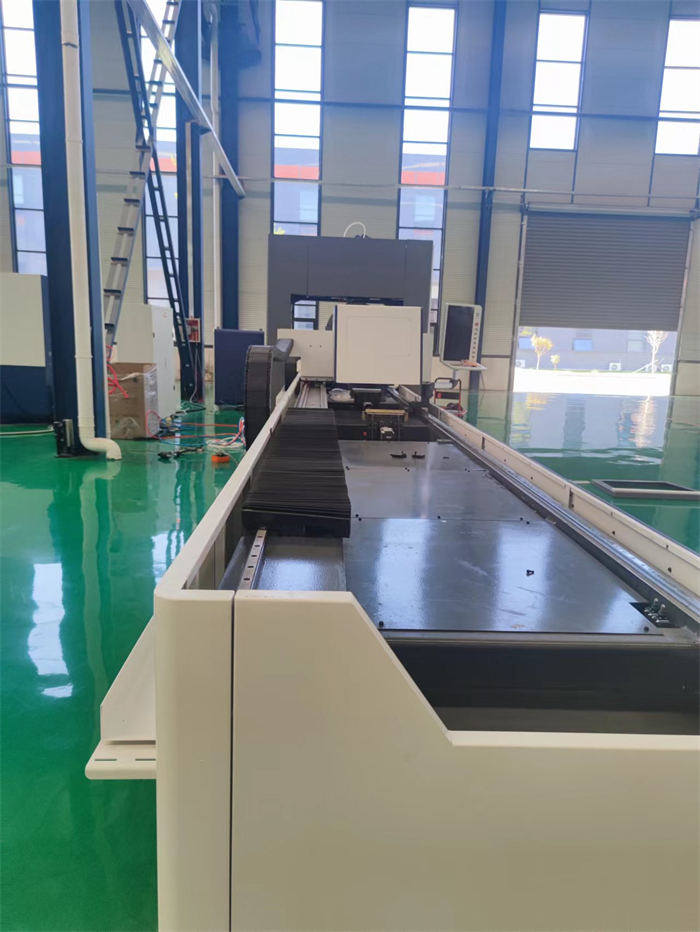

X axis route:6000 mm

Z axis route: 240 mm

X, Y Axis Orientation Precision: 0.03 mm/m

X/Y Axis Repeat Precision: 0.02 mm/m

Maximum positioning: 240 m/min

Speed Red light positioning: Yes

Auxiliary gas: N2, O2, Compressed air