How to maintain the CNC fiber laser cutting machine?

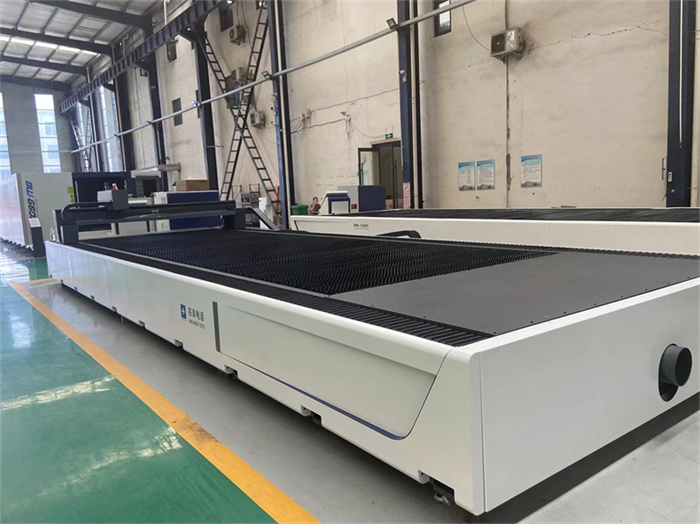

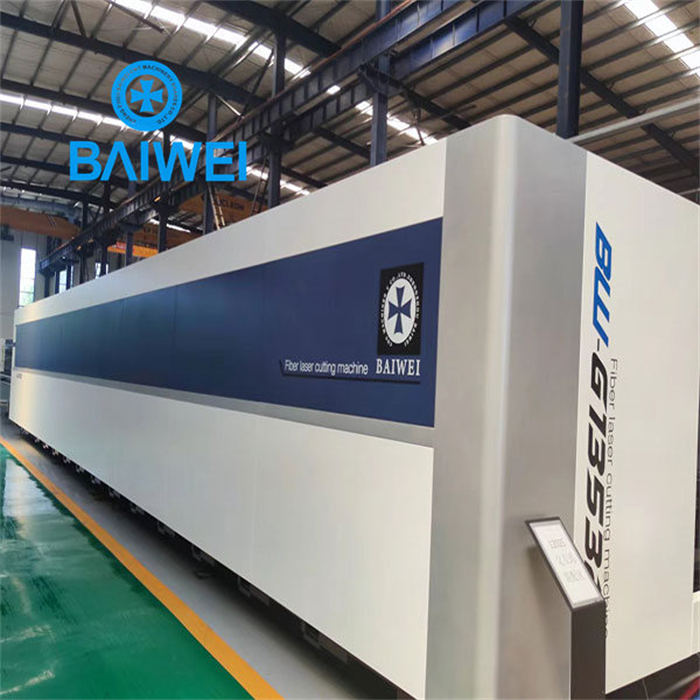

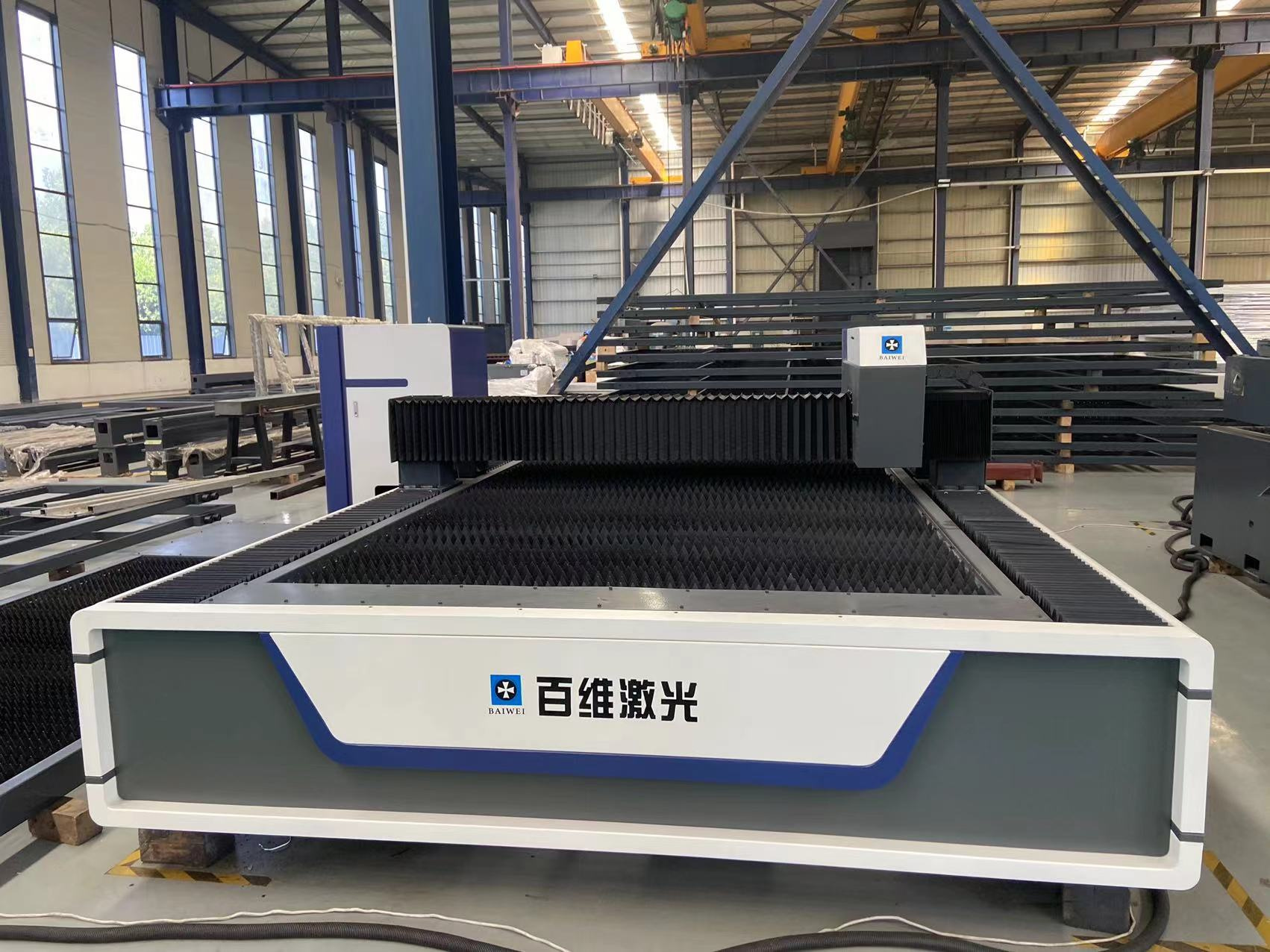

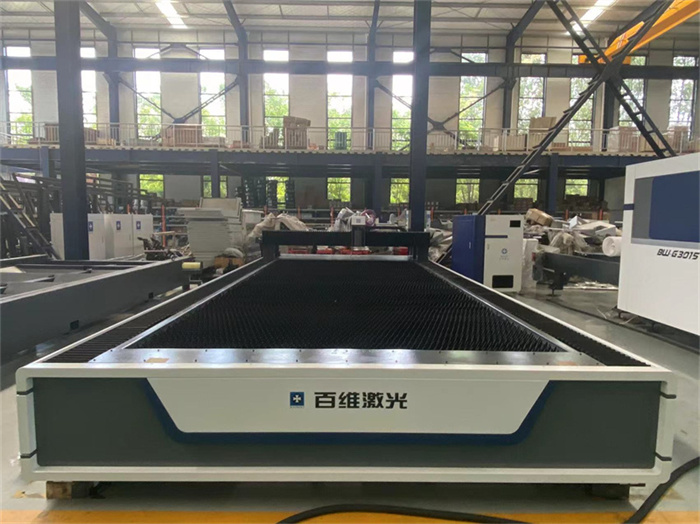

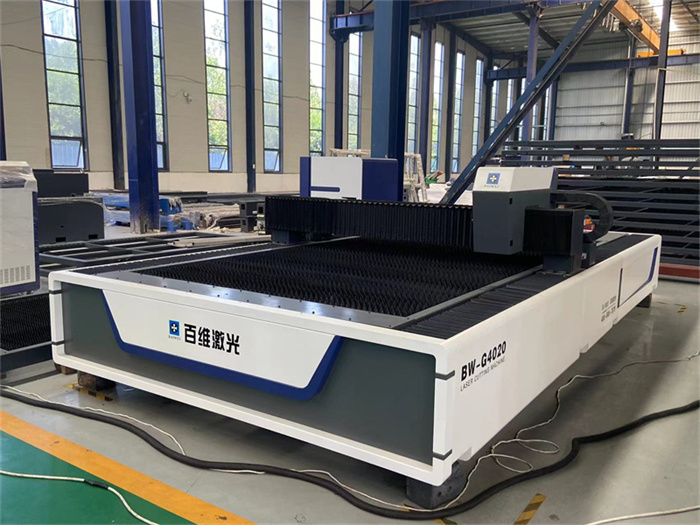

The fiber laser cutting machine is a high cutting precision and high value of machine, the daily maintain is very important for the machine. And the mainly maintain for the machine including the Cutting Head, Lens, Water Temperature, Rail Frame.

The maintenance of the lens for the fiber laser cutting machine is very important, and also ensure the quality of the beam. Before starting the fiber laser cutting machine, check the mirror first to check whether there is dust on the mirror surface or whether the mirror surface is damaged, in case after start, it will burn the laser source.

For the cutting head, before start machine, needs to check if the laser is emitted from the center of the nozzle, if not, needs recalibrate it.

About the water temperature, In order to prevent condensation, the water temperature humidity should be adjusted in time according to the seasonal temperature and air humidity. If the temperature is very low, especially in winter, the antifreeze must be added to the water tank, in case the freezing and damage of the water pipes.

For the Maintenance of the rail, they need be cleaned regularly and remove dust, other debris to ensure the normal operation of the equipment. The frame should be wiped and lubricated frequently to ensure the cutting is smoothly.

What’s more, we need also pay attention to the working environment.

The machine working environment must be pollution-free, free from interference and influence from strong electricity, strong magnetism, etc. And also anti-vibration and anti-loose. The fiber laser cutting machine is particularly sensitive to vibration, it will let the machine loose cutting precision.