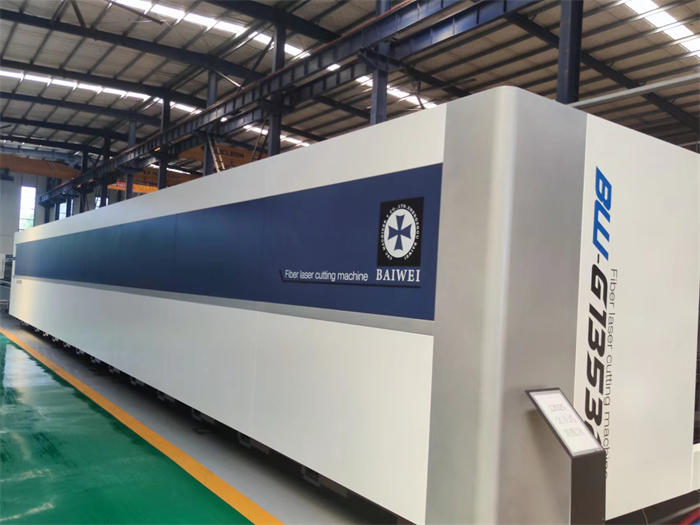

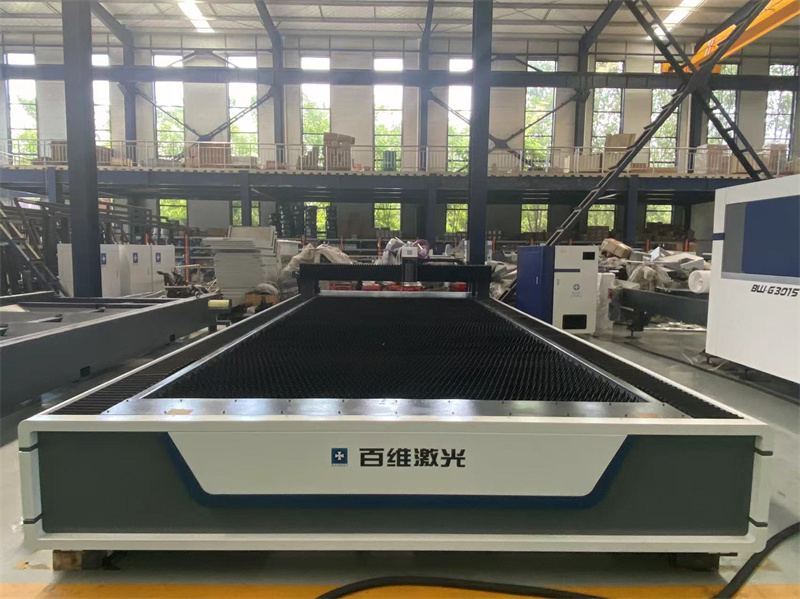

Hundreds of Light Cutting Machines ——Mid-High Successful Light Cutting Machine Manufacturers

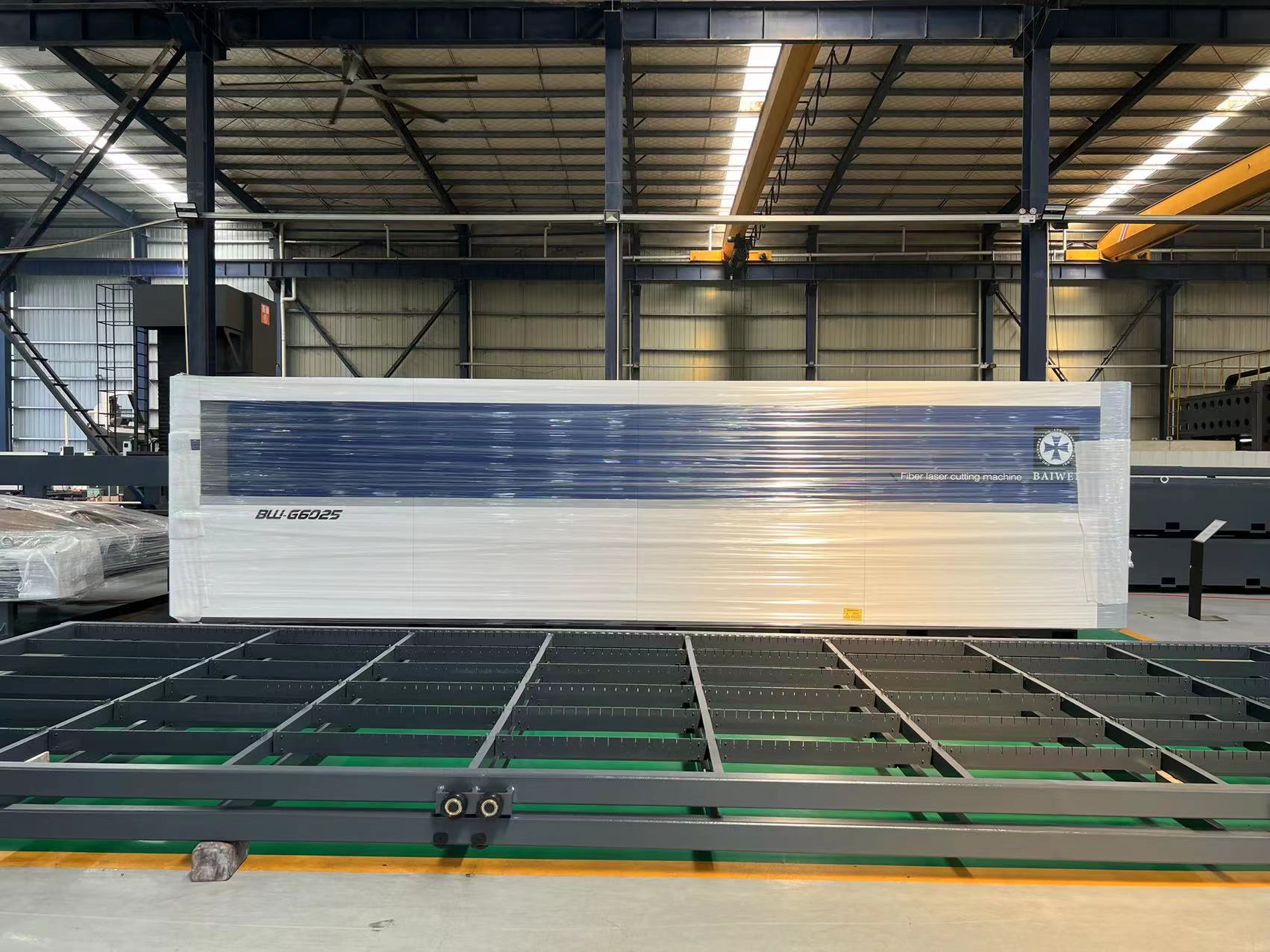

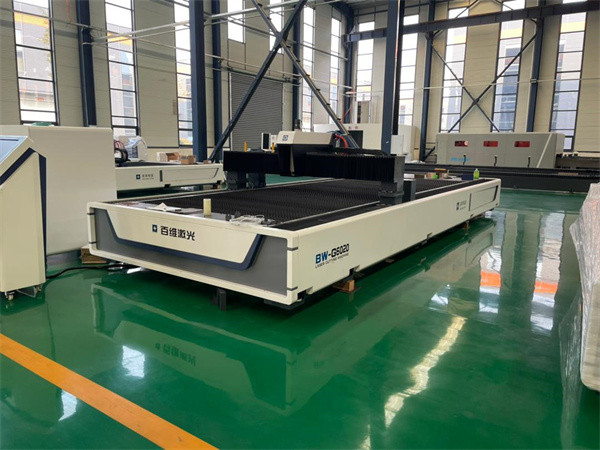

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

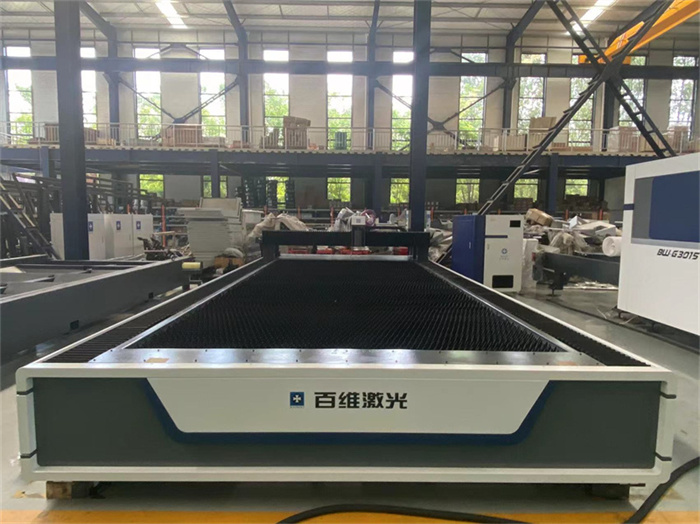

High precision machine bed

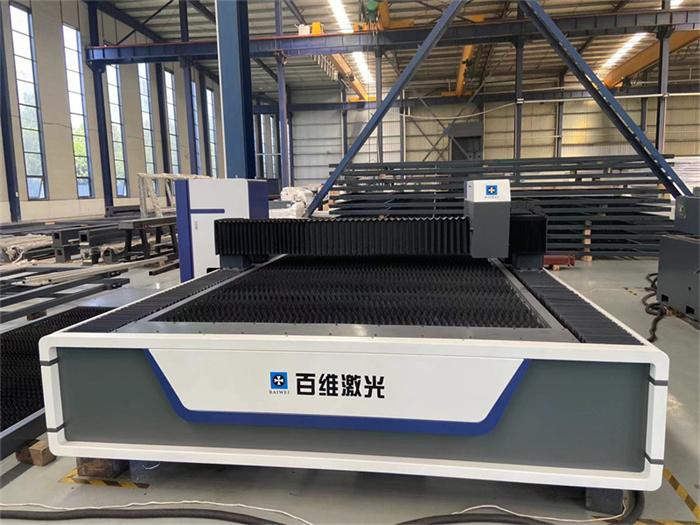

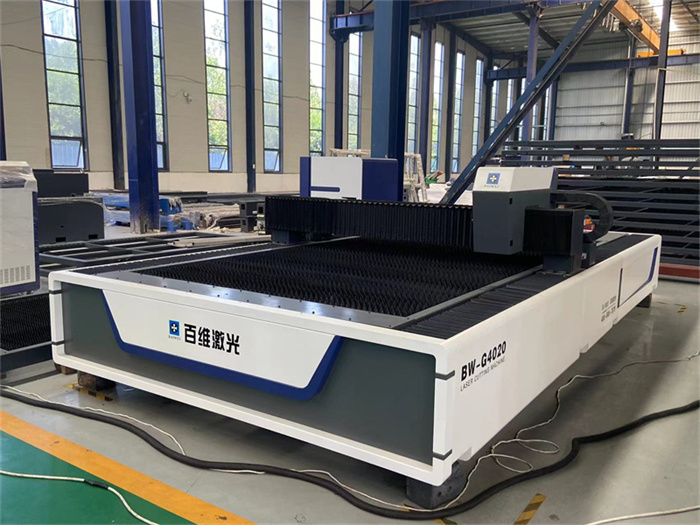

1. Fiber laser cutting machine lathe bed part completely independent research and development, by the party welding lathe bed base, through the large gantry milling machine.

2. For large machine bed we have many years of experience in processing, each machine bed will be placed 30 to 45 days after rough machining natural failure, the internal stress release completely again after finishing, ensure the machining accuracy. High strength, stability, ensuring 10 years of use without distortion.

Advantage of fiber laser cutting

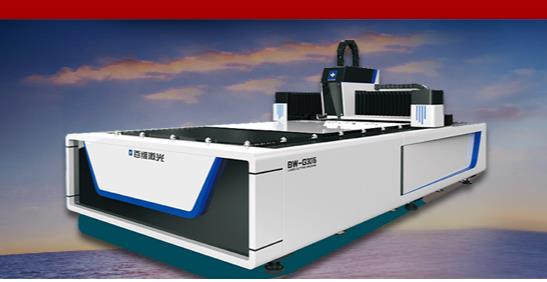

1. Adopting gantry dual drive structure, high precision gear, gear reducer drive and linear guide rail, drive smoothly, high speed, high accuracy.

2. The imported servo motor is Germany, America original imported servo motor (Various options ) and drive system,with higher stability, higher speed and faster acceleration speed.

3. Using the special control system of optical fiber laser, all digital CNC servo motor communication, humanized design, operation is faster.

4. The optical fiber laser cutting head and Z-axis transmission system are adopted, and the speed and precision are higher.

5. Adopting leading technology, small volume, high beam quality.

6. The new peripheral design can enter the equipment working area from 3 different directions.