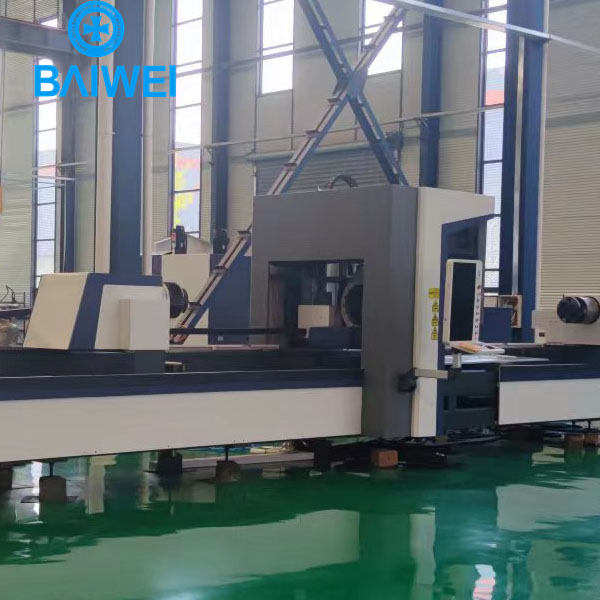

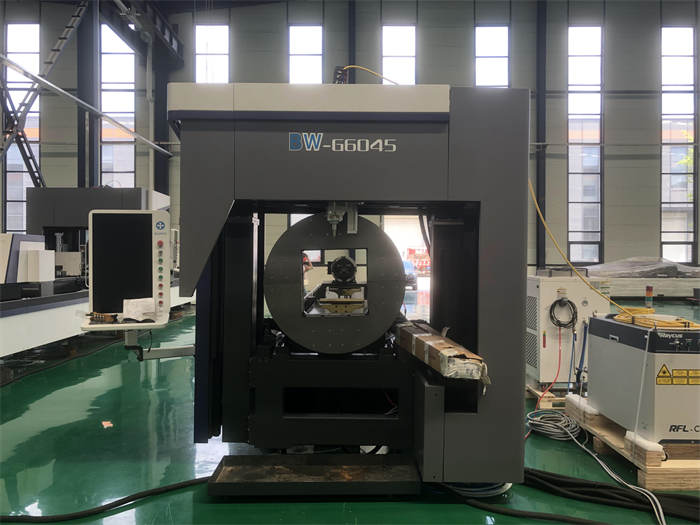

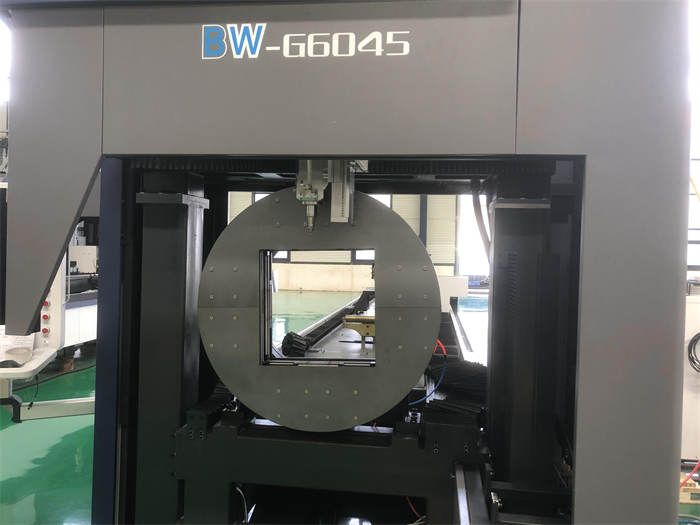

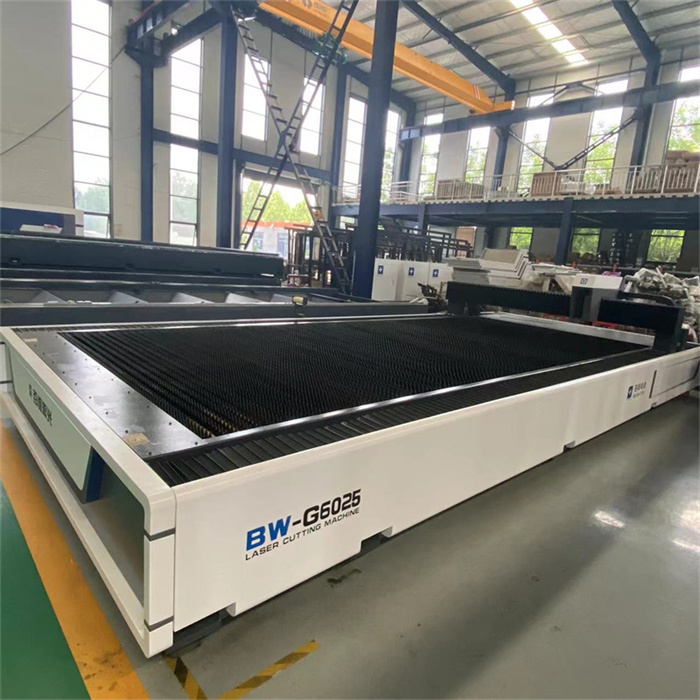

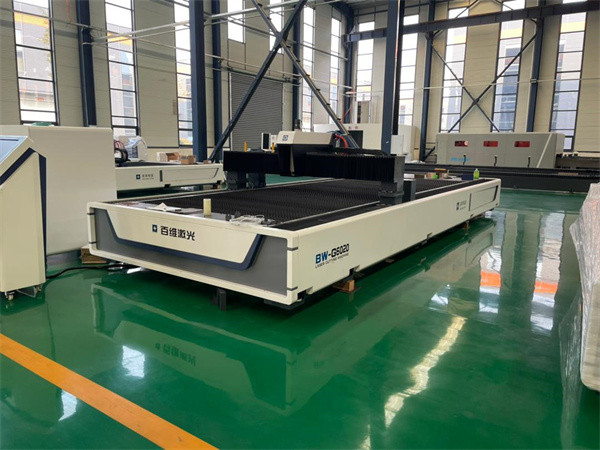

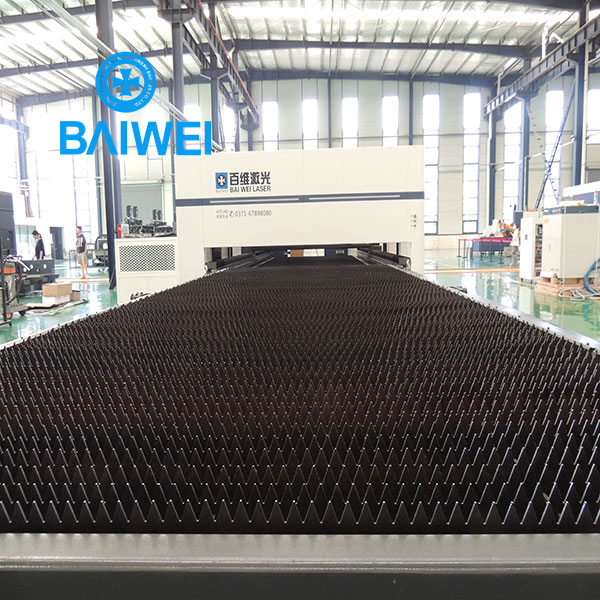

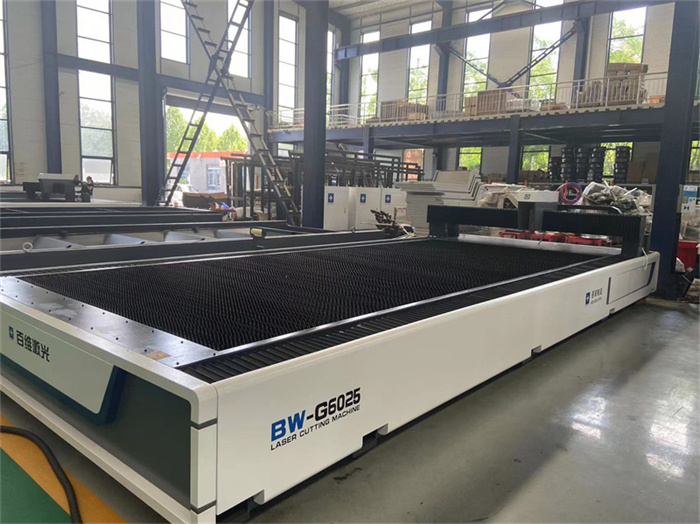

Iron casing parts closed type fiber laser cutting machine for sale

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

How do I use a laser cutting machine to cut high-quality workpieces?

When using a laser cutting machine to cut thicker or higher precision parts, the cutting process requirements are relatively high, so what are the factors that affect the cutting quality of the laser cutting machine?

1. The thickness of the metal material

With the development of fiber optics technology, the wattage of fiber laser cutting machines is also increasing, and the thickness of the metal that can be cut is also increasing. The thickness of the metal sheet to be cut must correspond to the relative wattage of the laser cutting machine to achieve better results.

2. Cutting speed

Cutting speed too fast or too slow will affect the cutting quality. The laser cutting speed needs to be determined according to the material and the thickness.

3. The roughness of the material surface

Laser cutting machine processing is not limited by the shape of the material, but the surface roughness of the material determines the quality of the cutting. The smoother the material surface, the better the cutting effect. The smoother the material surface, the better the cutting effect. Therefore, in order to maintain the cutting quality, try to choose materials with smooth and rust-free surfaces.

4. Cutting focus

The position of the focus is one of the key points of cutting quality. Only with accurate focus can the ideal cutting be achieved.