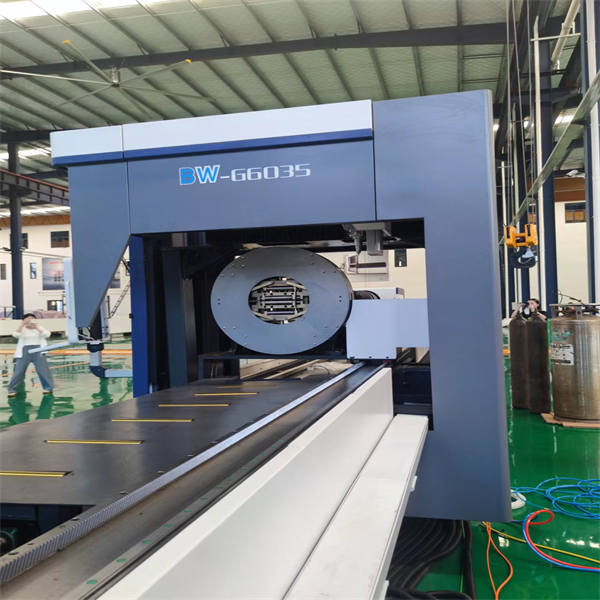

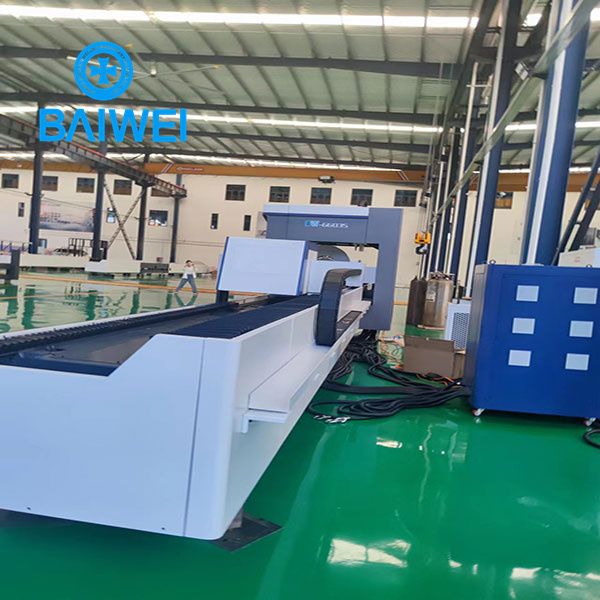

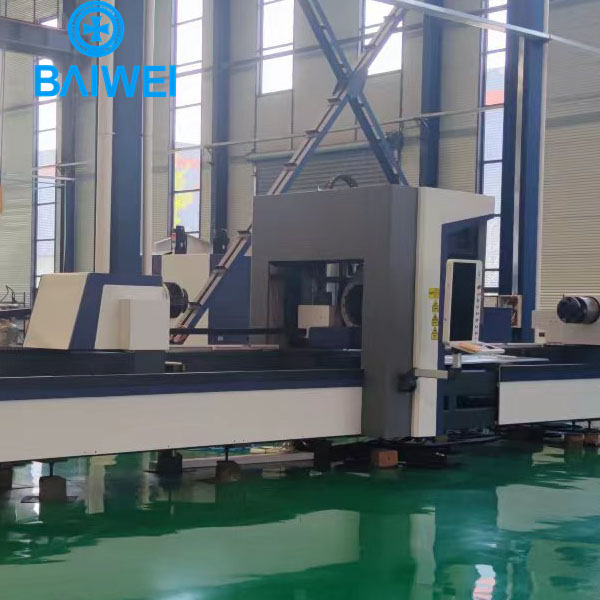

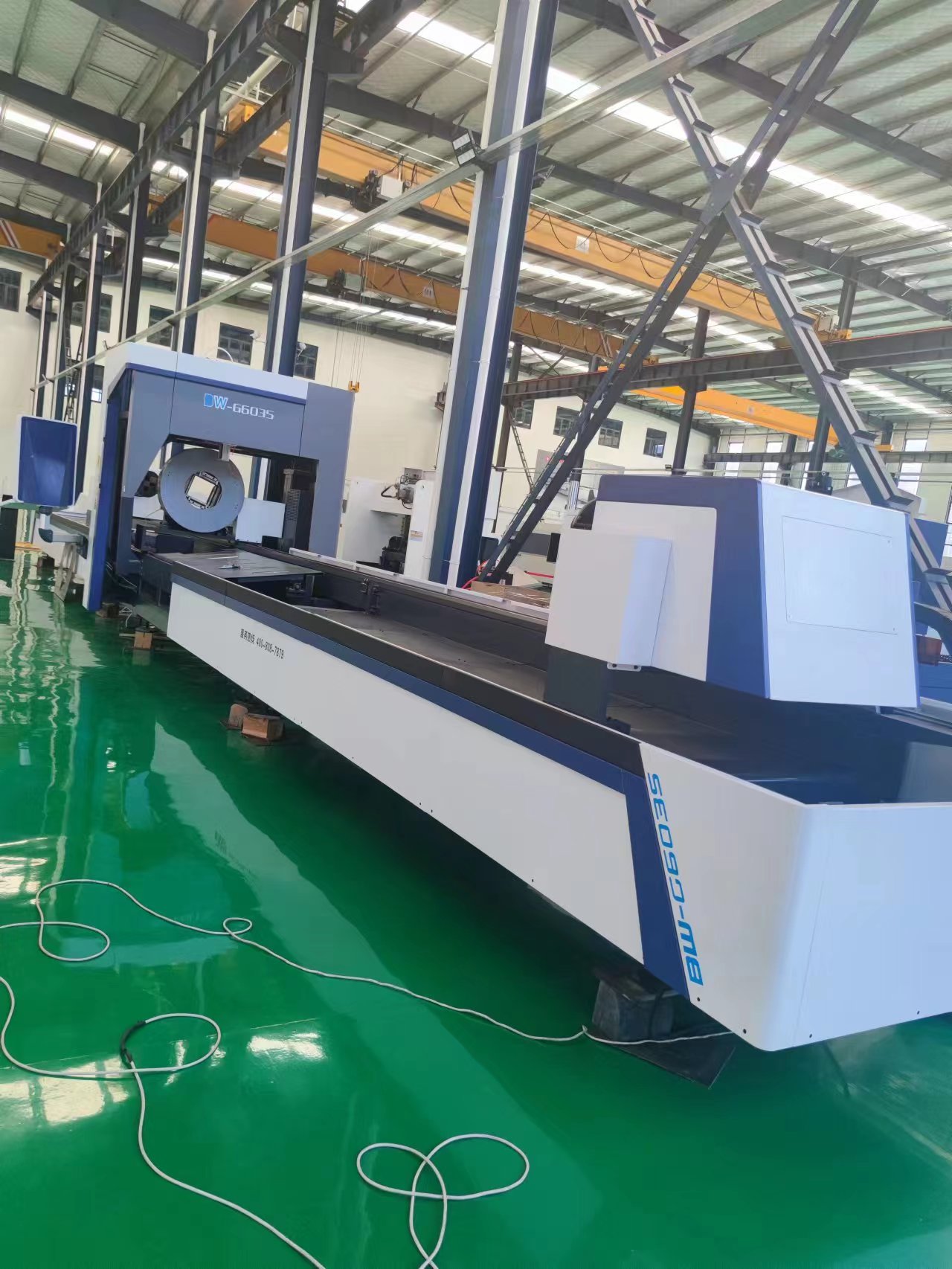

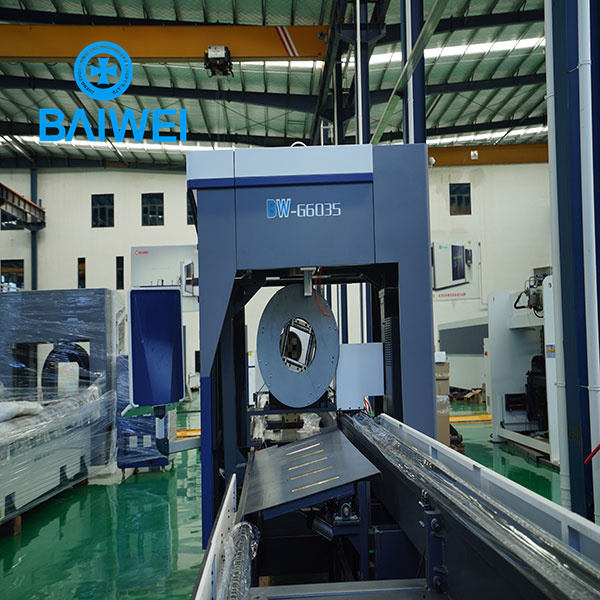

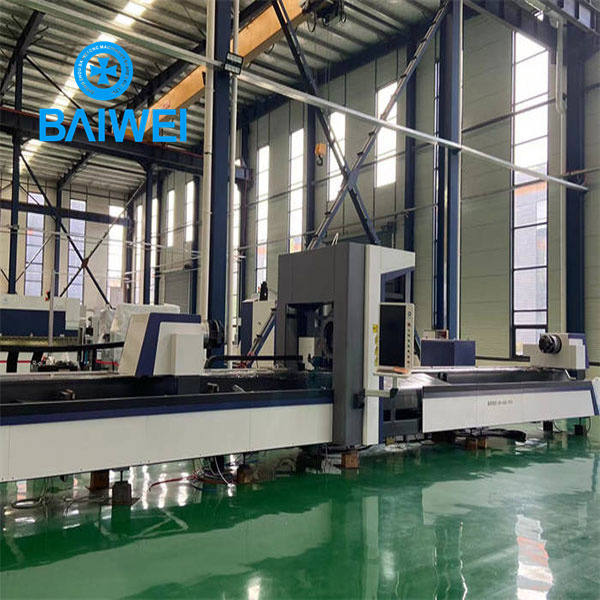

Limited time special closed laser cutting machine spot

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

1. Fine cutting seam: the laser cutting seam is generally 0.1mm-0.2mm

2. The cutting surface is smooth: the cutting surface of laser cutting has no burrs and dross.

3. Small thermal deformation: Laser processing has thin laser slits, fast speed, and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

4. It is suitable for the processing of large-sized products: the mold manufacturing cost of large-sized products is very high, and laser processing does not require any mold manufacturing. For this, we suggest changing the machine needle to a thicker size, and at the same time try to adjust the feeding time of the feed dog Slow down to fix this problem. Moreover, laser processing completely avoids the edge collapse formed when the material is punched and sheared, which can greatly reduce the production cost of the enterprise and improve the grade of the product.

5. It is very suitable for the development of new products and shortens the R&D cycle: once the product drawing is formed, laser processing can be carried out immediately, and you can get the real product of the new product in the shortest time.

6. Saving materials: Laser processing adopts computer programming. Laser equipment can cut products of different shapes into materials. Different combinations of upper and lower thread thicknesses of interlock sewing machines will definitely produce different sewing effects. Under normal circumstances, the upper and lower wires should be selected to be the same thickness, but sometimes we do not pay attention in actual operation. We choose thick upper wires and thinner lower wires to maximize the utilization of materials.