Home » Fiber Laser Cutting Machine » Professional laser pipe cutting machine realizes automatic feeding and zero-tail cutting of heavy-duty pipes

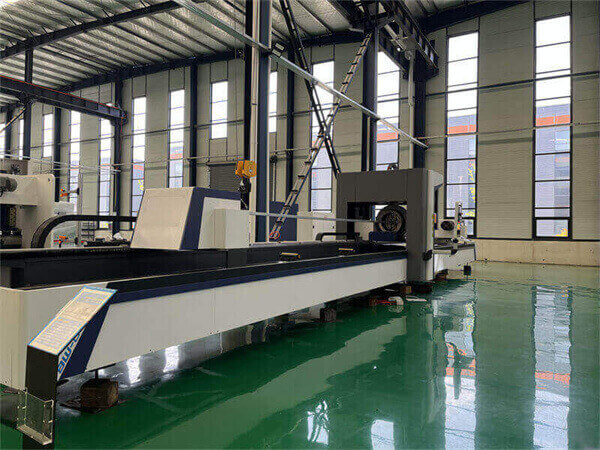

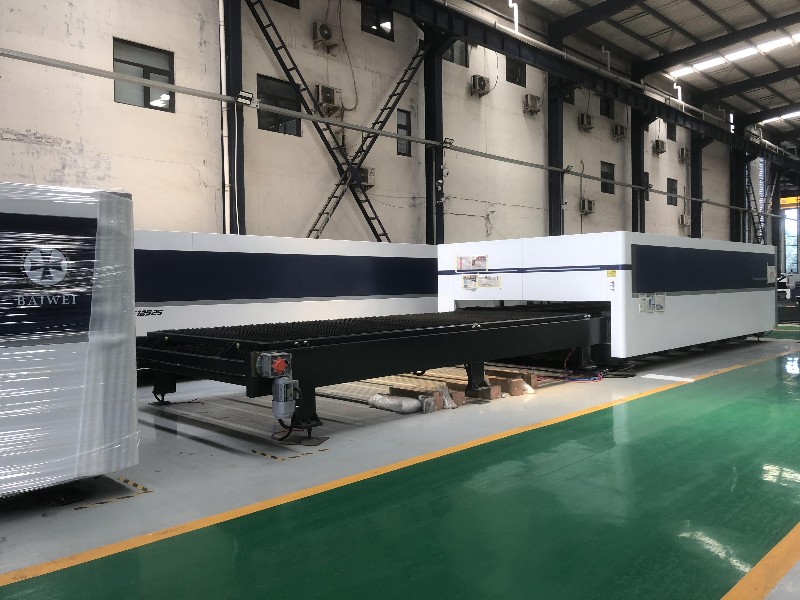

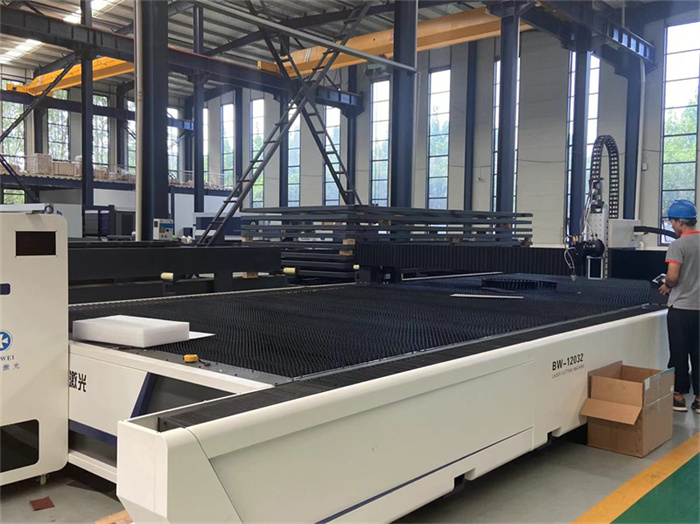

Professional laser pipe cutting machine realizes automatic feeding and zero-tail cutting of heavy-duty pipes

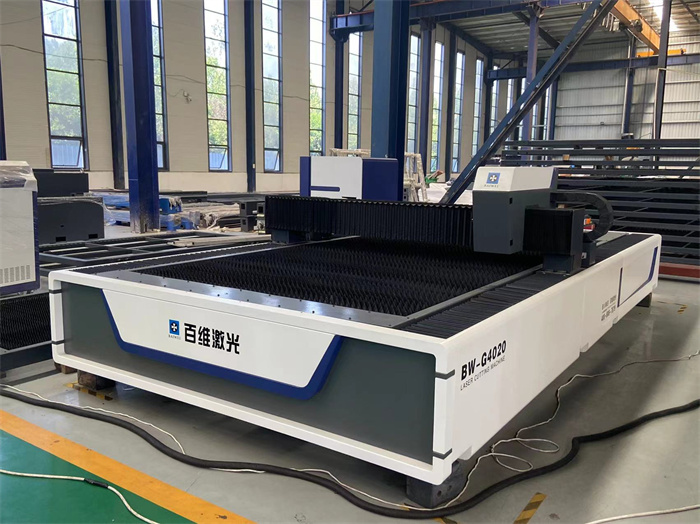

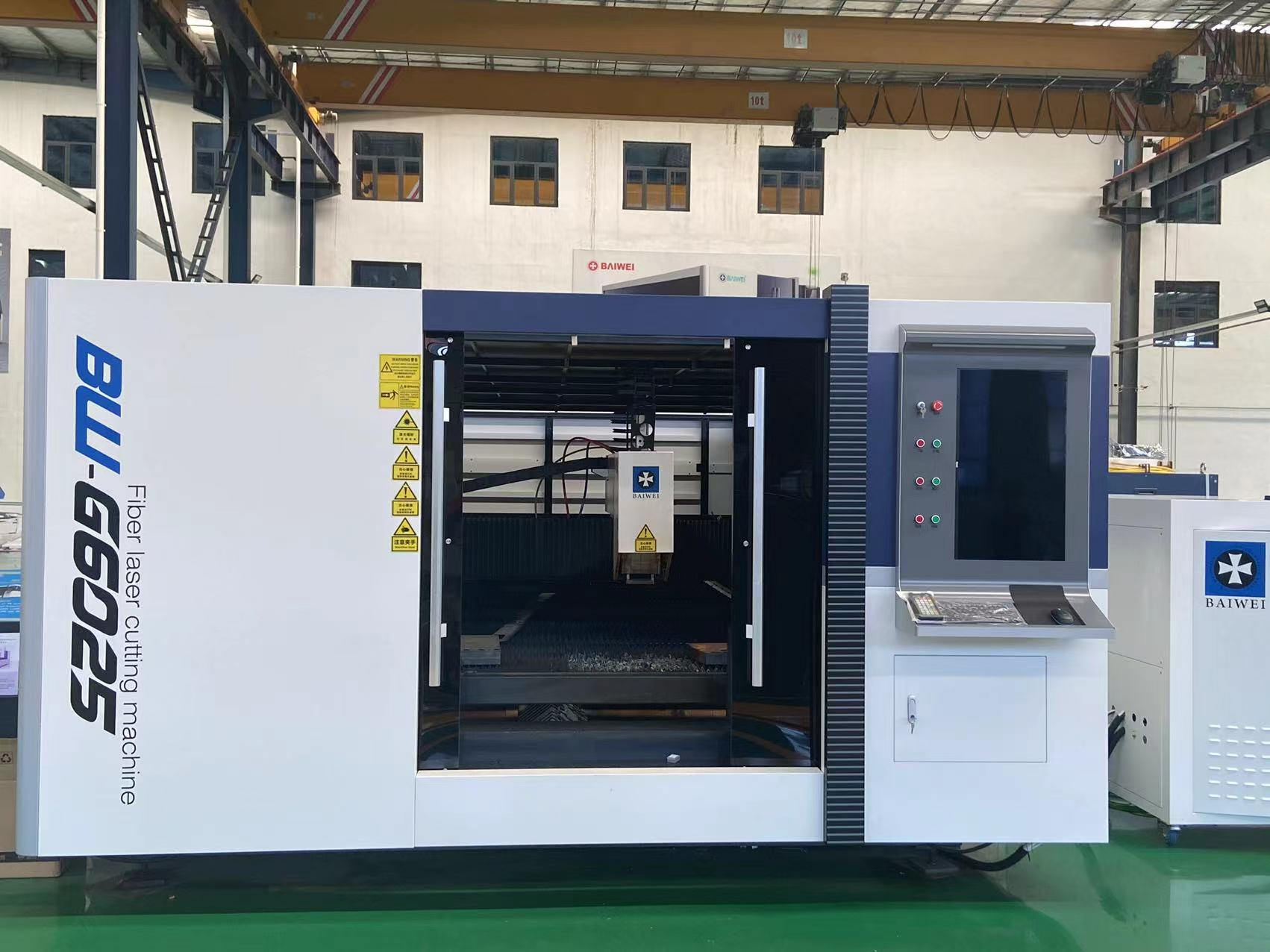

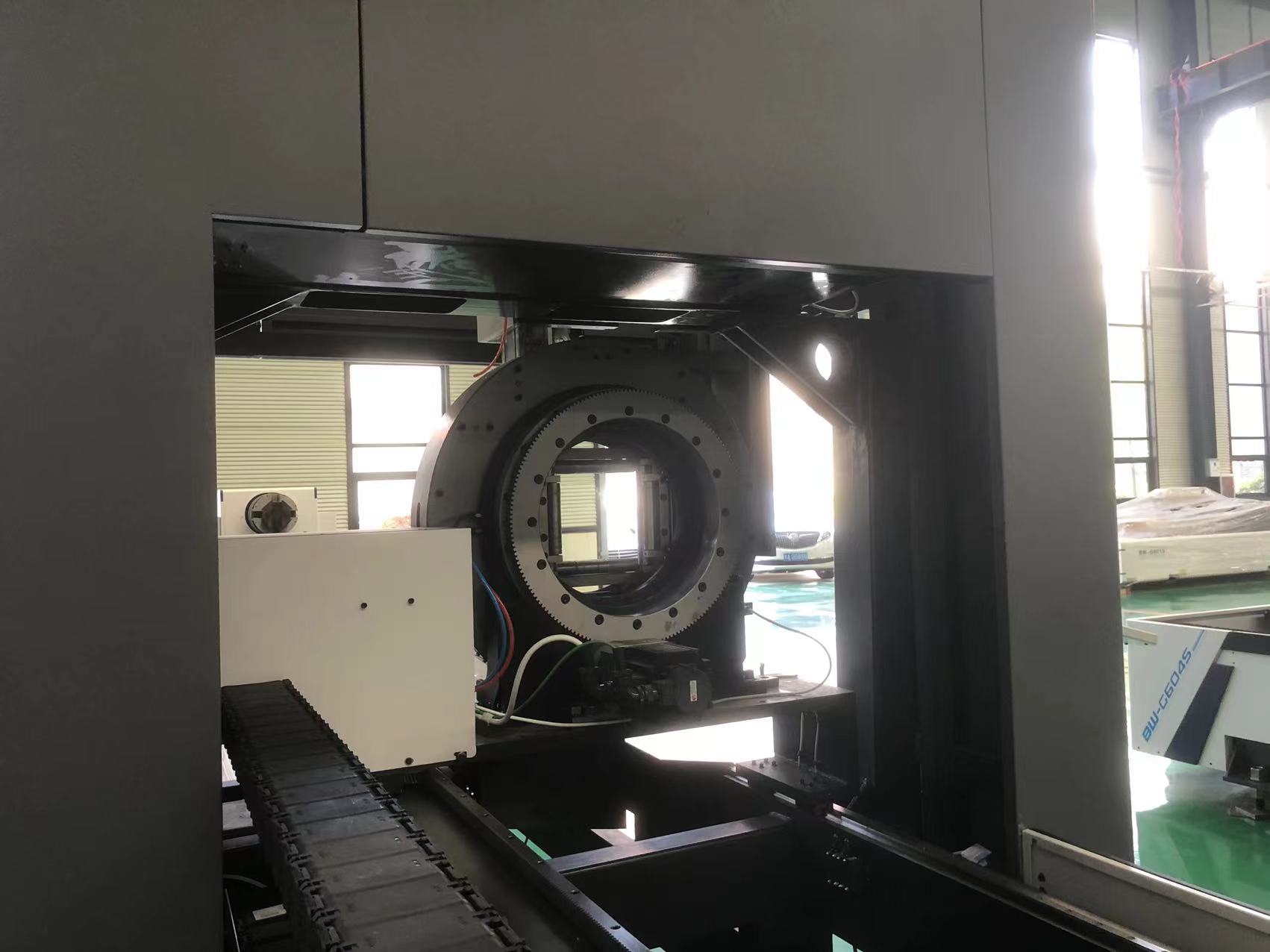

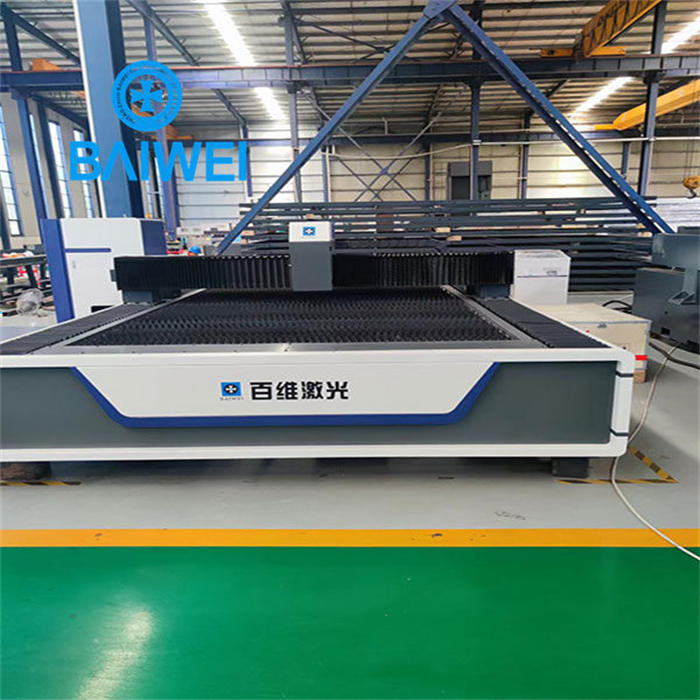

Model:BWQG6016-6000*160 professional tube laser cutting machine

Power:3kw/4kw/6kw/8kw

Cutting diameter: ≤499mm

Cutting length: 6000mm/9000mm/12000mm

Contact US

Get Price

Share:

Content

Why are lasers used for cutting? How does laser cutting work?

Laser cutting refers to that the horizontal laser beam emitted by the laser is changed into a vertical downward laser beam through a 45 ° total reflector, and then focused by the lens to form a tiny spot at the focus. When the spot shines on the material, the material will soon be heated to the vaporization temperature and evaporated to form holes. With the movement of the beam on the material, and with the help of auxiliary gas (carbon dioxide gas, oxygen, nitrogen, etc.), the molten waste slag will be blown away, Make the hole continuously form a slit with a very narrow width (such as about 0.1mm) to complete the cutting of materials.

Inquiry

More Fiber Laser Cutting Machine