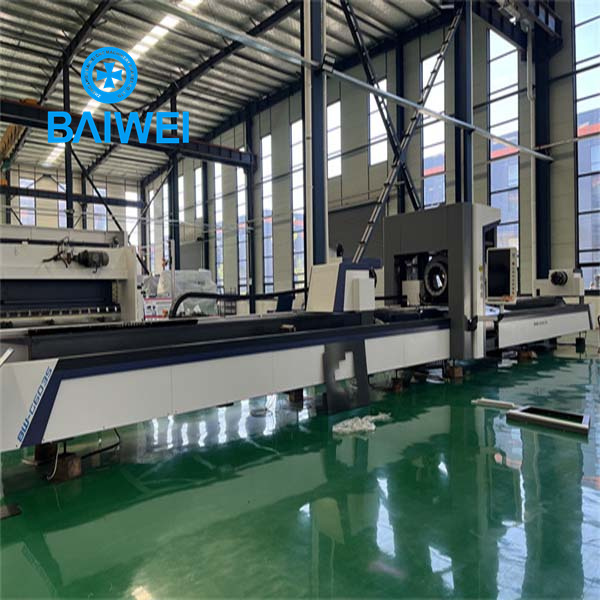

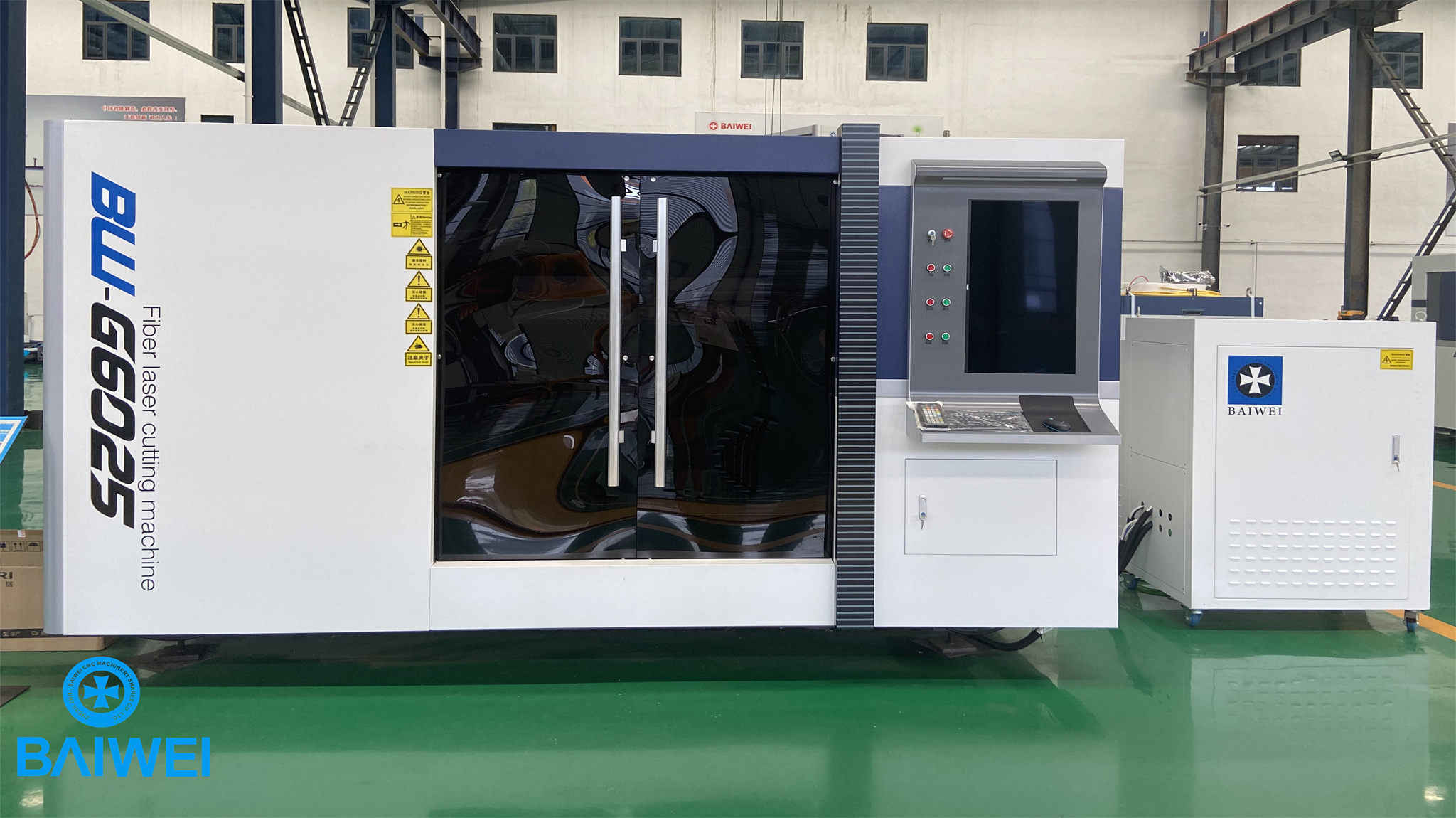

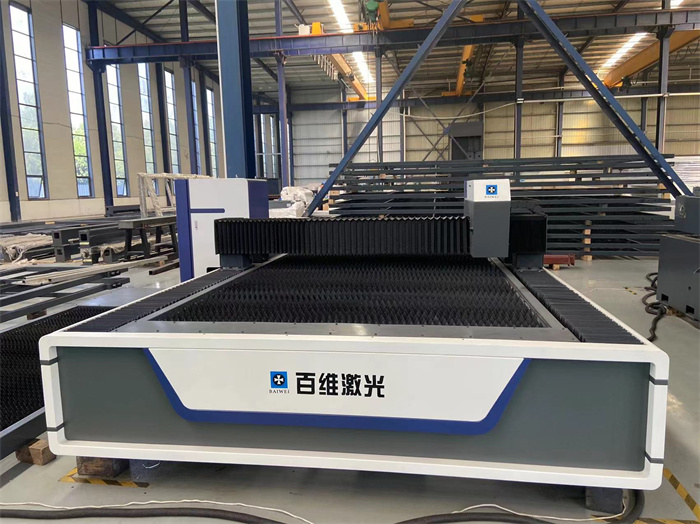

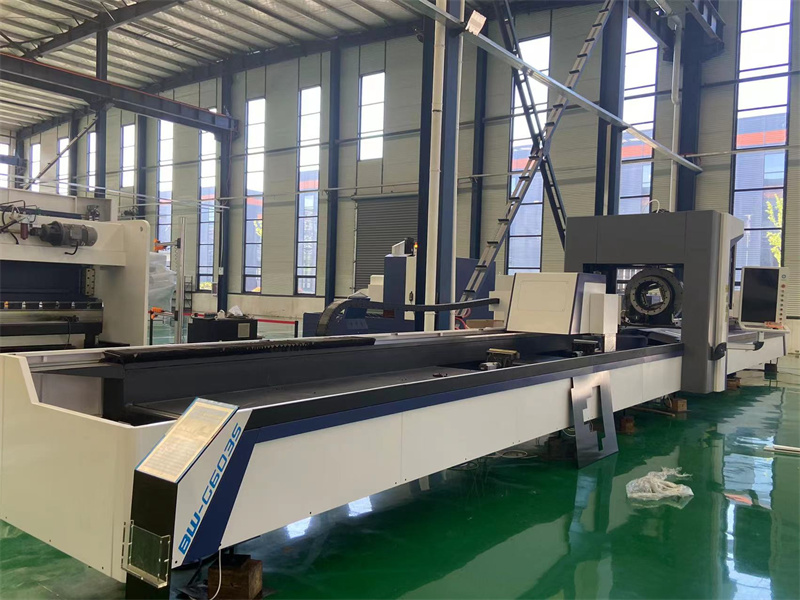

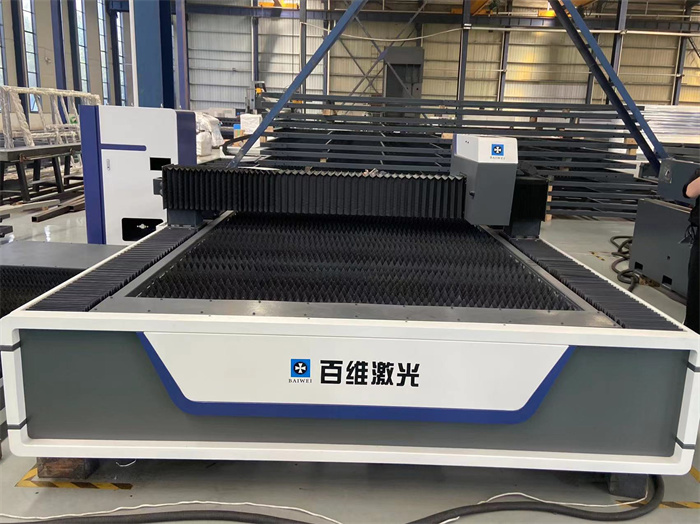

Steady closed type fiber laser cutting machine for metal castings

The fully enclosed protection of the enclosed fiber laser cutting machine improves the safety of use. The laser protective glass of the enclosed fiber laser cutting machine can protect the human body from laser radiation.

Laser Power:12kw/15kw/20kw/30kw (Optional)

Laser Source:IPG/Nlight/Raycus

Processing Surface (L*W):13500*3200mm/13500*2500mm/12500*3200mm/12500*2500mm/10000*3200mm (Optional)

Position Accuracy X, Y and Z Axle:+0.03MM

Cutting Thickness:Carbon Steel 0.5MM-40MM, Stainless Steel 0.5MM-40MM

How long is the service life of a CO2 laser cutting machine?

The service life of a CO2 laser cutting machine mostly depends on the consumables inside of the machine, there are 3 major parts that you need to pay attention to: the laser

tube, the focus lens, and the mirror. As the time you use the machine gets longer, these 3 consumables, especially the laser tube would likely appear some issues, that¡¯s when

you need to replace it.

With that said, if you use a laser engraver regularly (not heavy duty), a high-quality laser tube can allow you to use it over 2000 hours without appearing any problems, but

if you are using the machine to due with some heavy-duty, which requires the machine to work with its largest power, the tube can stand about 500 hours.