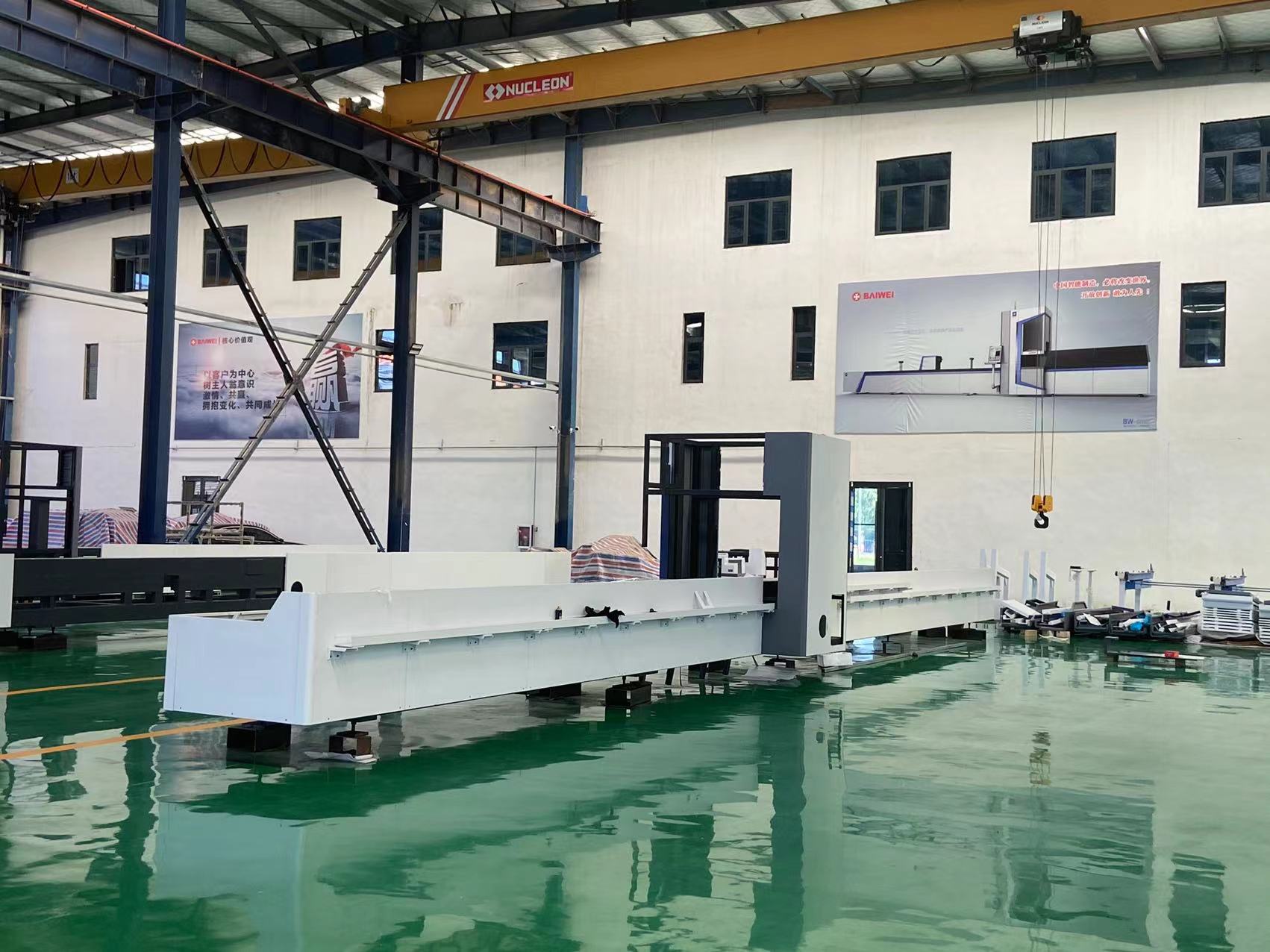

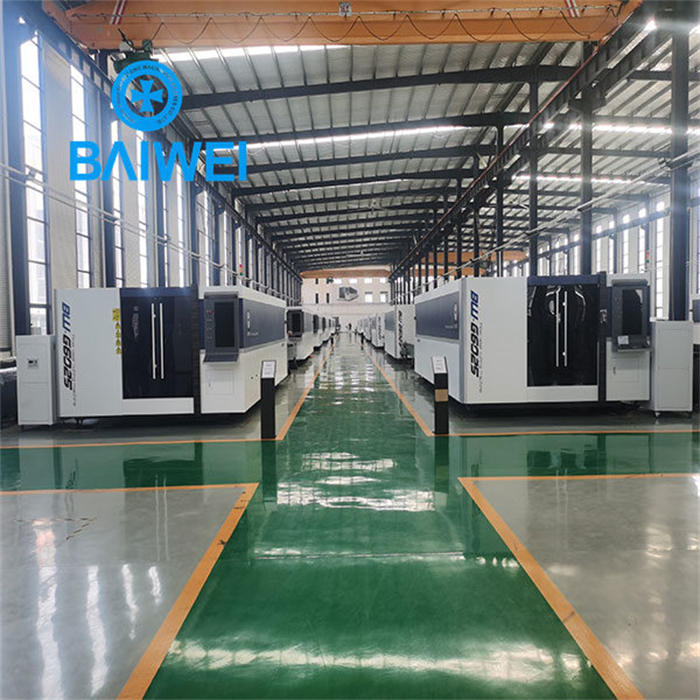

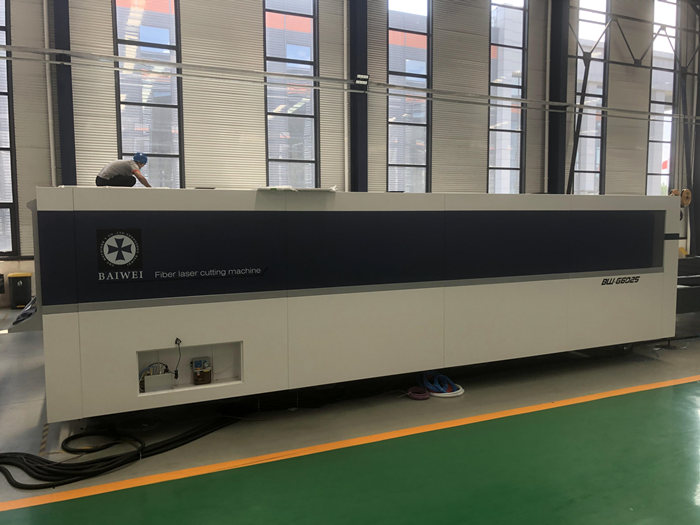

Steady closed type fiber laser cutting machine with precison machining

The enclosed fiber laser cutting machine can effectively avoid laser pollution. The enclosed fiber laser cutting machine can also protect the safety of operators during the production process and improve the safety factor.

Laser Power:12kw/15kw/20kw/30kw (Optional)

Laser Source:IPG/Nlight/Raycus

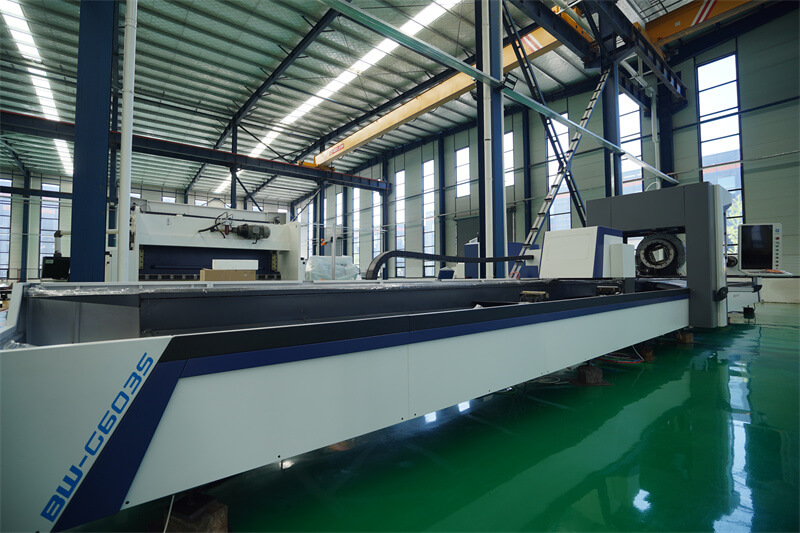

Processing Surface (L*W):13500*3200mm/13500*2500mm/12500*3200mm/12500*2500mm/10000*3200mm (Optional)

Position Accuracy X, Y and Z Axle:+0.03MM

Cutting Thickness:Carbon Steel 0.5MM-40MM, Stainless Steel 0.5MM-40MM

Do you know How Fiber laser Cutting Machine Work?

Fiber laser cutting machine is one of the laser cutting equipment, which utilizes light power to pierce the processing material. In comparison with normal light source, laser

generator has its unique character, like great directionality, monochromaticity, coherence and energy concentration. Among these factors, monochromaticity depends on the

frequency stability, while the best monochromaticity could be realized by the gas laser generator.

If you want to improve the quality of monochromaticity, frequency stabilization technology and mold selection technology could be adopted.

The basic operation principle is the photoelectric conversion, the laser generator is driven by the electronic power, and transport the optical fiber into the cutting head.

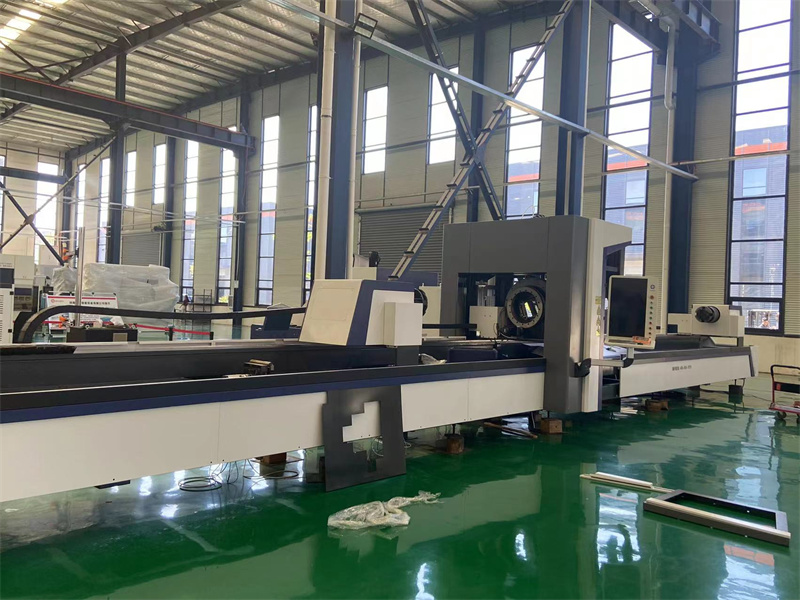

Have you ever noticed the structure of the cutting head?

It is composed by 13 parts, including artifact, nozzle, oxygen intake pipe, nitrogen pressure gauge, lens cooling water jacket, focusing lens, laser beam, reflector, reflector

cooling water jacket, servo motor, ball screw, amplication control and drive motor and position sensor.

Laser beam is reflected by the reflector, and then it would pass through the focusing lens and nozzle, arriving at the surface of the metal sheet or pipe. In addition, nozzle

plays a critical role in the process of cutting and engraving. The laser head could avoid to be polluted by slag produced during the cutting since the nozzle could produce air

while operating the machine.

It¡¯ true that laser is the brightest light source in the world, hydrogen bomb could compare with it only at the moment of explosion. According to the scientific data, the

brightest of sunshine is about 103 watt square centimetre, while the output brightness of a high power fiber laser generator cold exceed 7 to 14 magnitude.

That¡¯s the reason why optical laser could easily reach the ultra-high temperature and high pressure at the part of material.