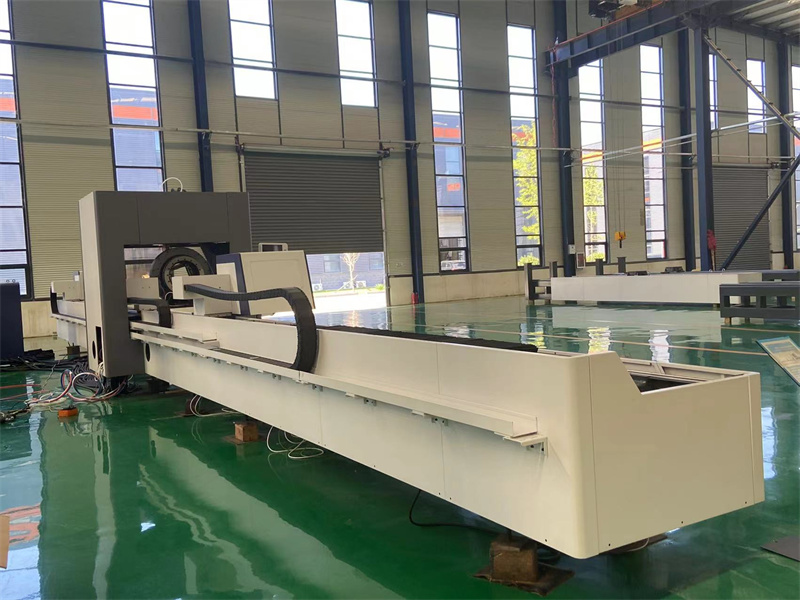

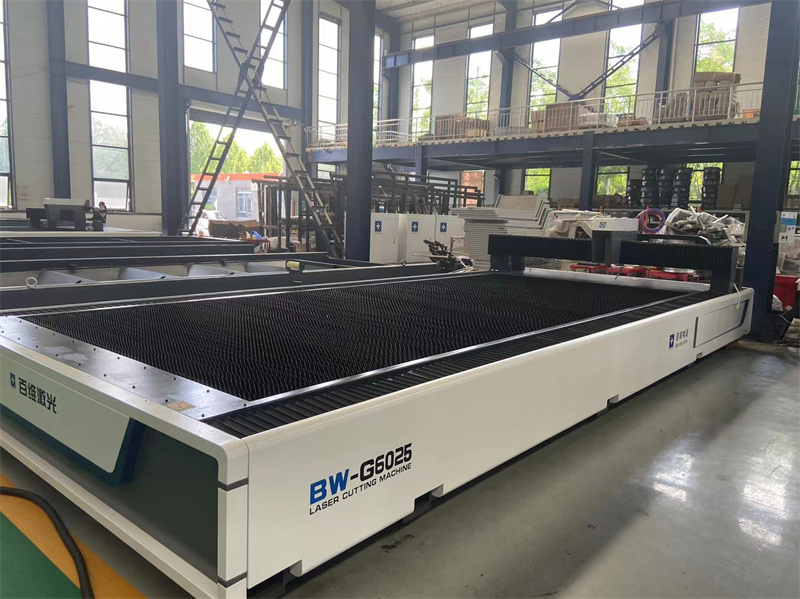

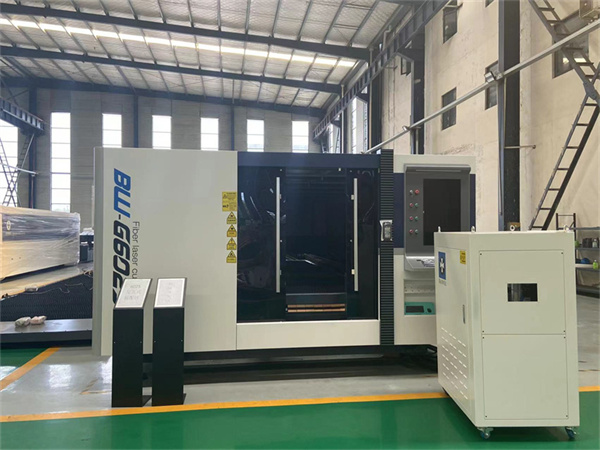

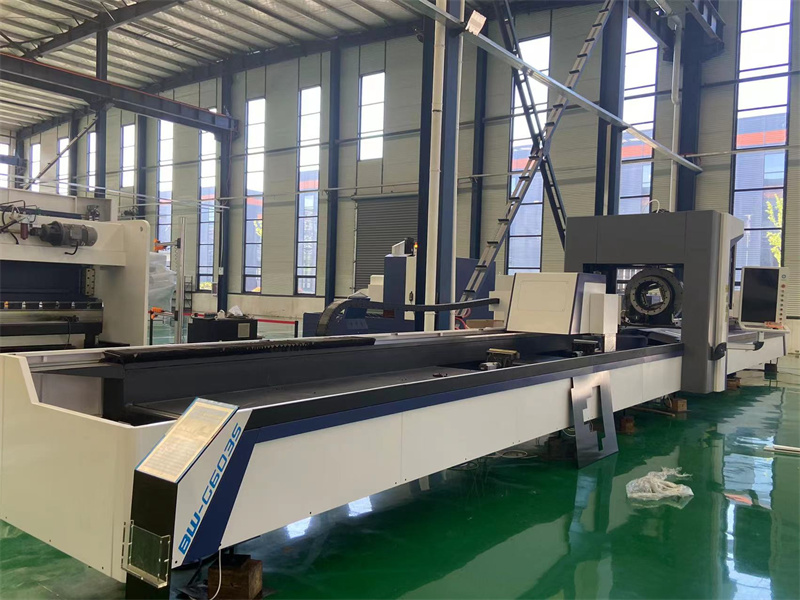

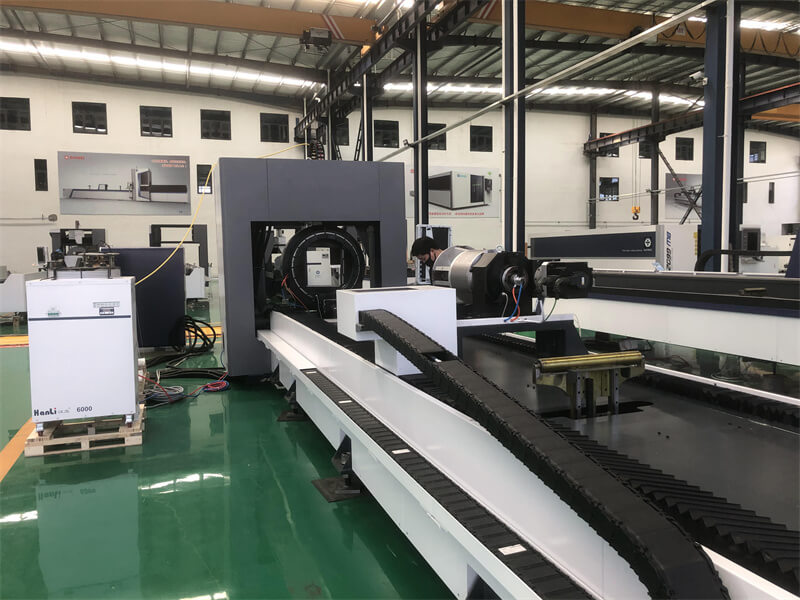

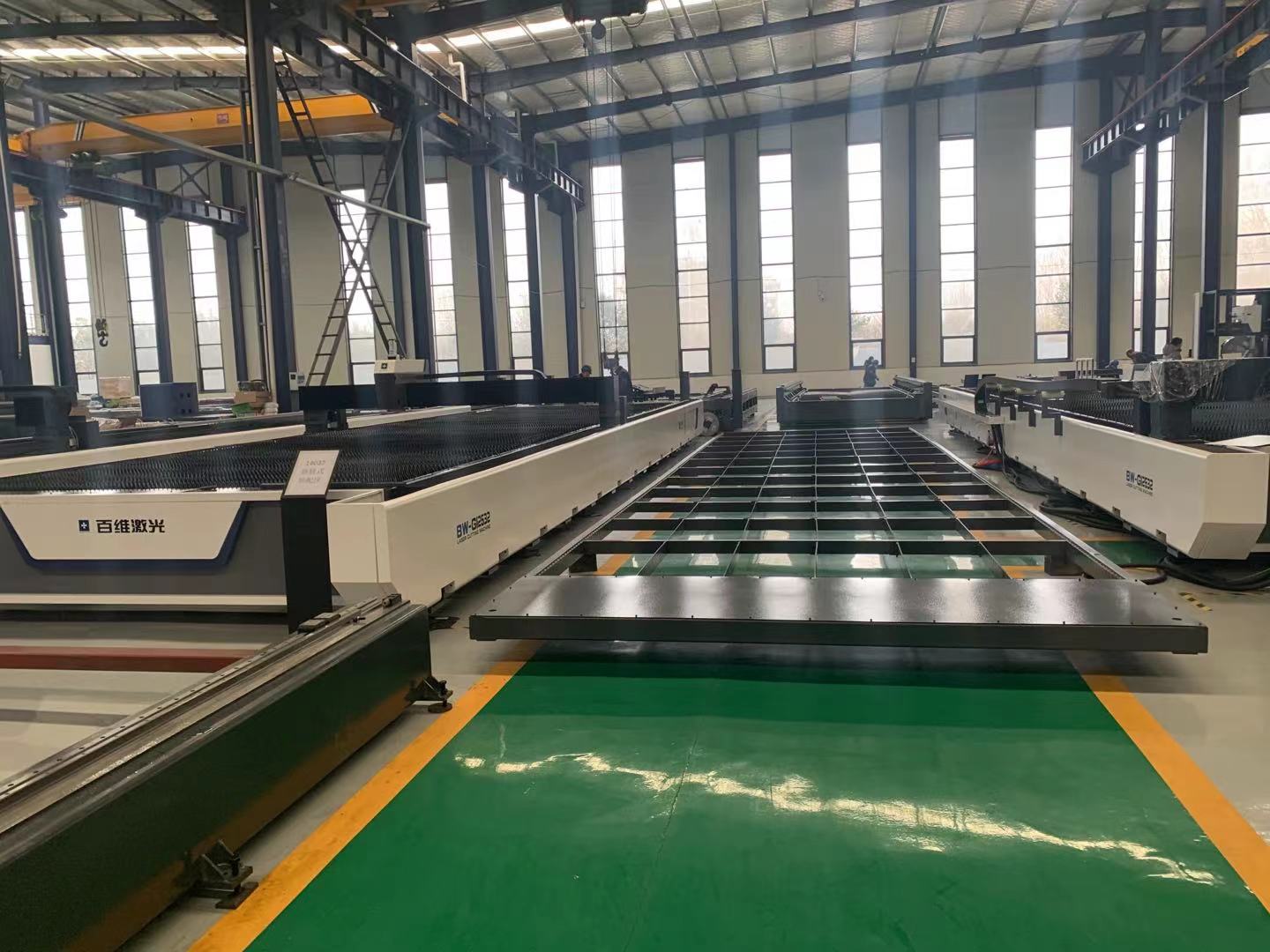

Supply automatic pipe cutting machine equipment round tube laser pipe cutting machine production line fiber laser pipe cutting machinery

Parameter

Model BW3000/BW6000/BW9000

Laser Generator Medium Fiber Laser Source

Output Power 3000W/4000W/6000W/8000W/12000W

Effective pipe cutting diameter 15-220mm

Working axial positioning accuracy <±0.05mm

Worktable reposition accuracy <±0.02mm

Working principle of laser pipe cutting machine:

1. Feeding rack: Before cutting starts, the whole bundle of pipes needs to be manually hoisted to the material rack, manually packaged and removed, and then placed on the automatic pipe conveying mechanism in sequence.

2. The pipes are placed on the conveying platform in turn, and the pipe conveying device can transfer the pipes to the feeding mechanism one at a time according to the requirements, and automatically replenish and stand by according to the pipes.

3. The feeding mechanism will automatically transfer the pipes in the waiting area to the automatic feeding mechanism according to the signal, and other pipes will be automatically filled and moved to the material position to ensure continuous operation.

4. The pipe positioning and calibration system calibrates the pipe position neatly as needed (the pipe material should not be placed beyond the outside of the feeding mechanism).

5. The feeding structure automatically sends the pipes to the material (lifting) shelving system of the machine tool according to the signal (one pipe at a time).

6. The feeding mechanism returns in time after receiving the signal of completion of shelving, and at the same time, the A rotating gripper device moves according to the signal – clamps – pushes it to the B rotating plate for perfect cutting.

7. The material shelving system automatically lifts and lowers according to the distance of the A rotating gripper device to avoid collision;

8. When the A rotating gripper device advances to the middle limit position of the B rotating support plate, the C rotating gripper device automatically runs to the right end of the B rotating plate to continue the perfect cutting of the tail material, so as to ensure the overall cutting of the pipe, basically zero tail material.

9. The automatic lifting type material receiving system rises to 15mm away from the rotation of the pipe, and catches the workpiece while the pipe is cut, so as to prevent the workpiece from falling naturally due to the weight of the pipe, the gap at the cutting point is too large, or it is dropped and deformed.

10. After the automatic lifting type material receiving system is finished, it will automatically drop to a fixed position, and at the same time, the material receiving box will be inclined, and the workpiece will naturally slide to the ground material collection bucket.

11. The feeding mechanism is on standby. Before the cutting of the previous pipe is completed, the material preparation is completed, and the operation program of the next pipe processing is carried out on standby.