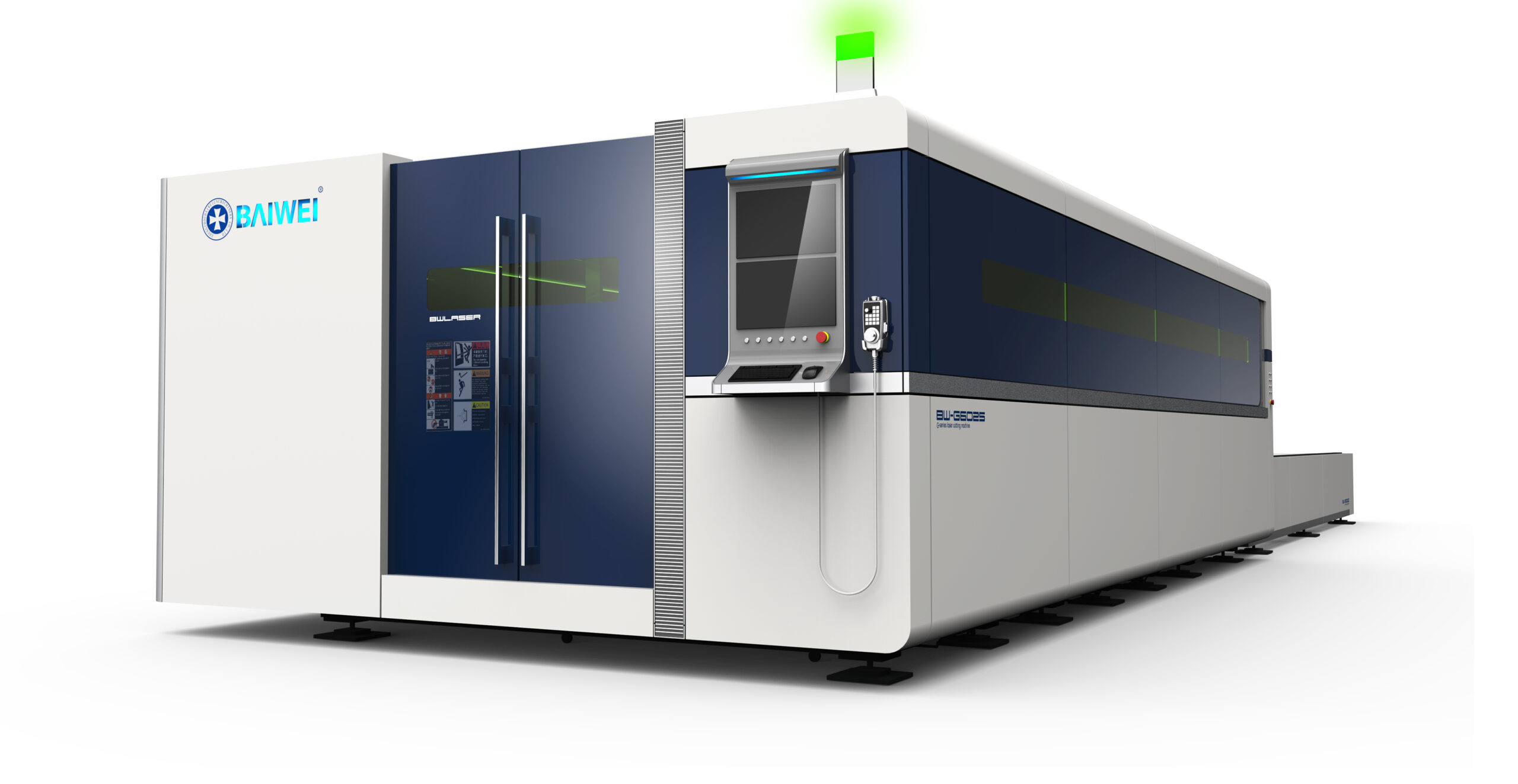

CNC Contral Laser cutters nearby 4000w

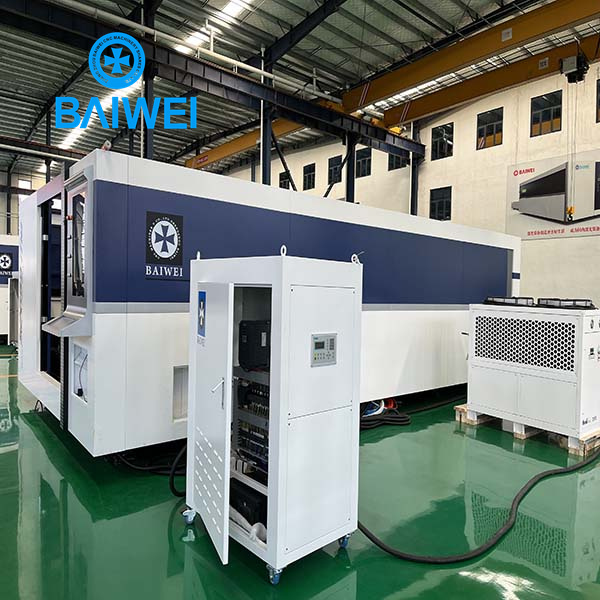

Zhengzhou Baiwei company adopts the original imported Renishaw laser interferometer from Switzerland, which is worth 30,000 US dollars. Test the linear accuracy of the machine tool guide rail after assembly, and perform precise compensation at the same time to reduce the accuracy error.

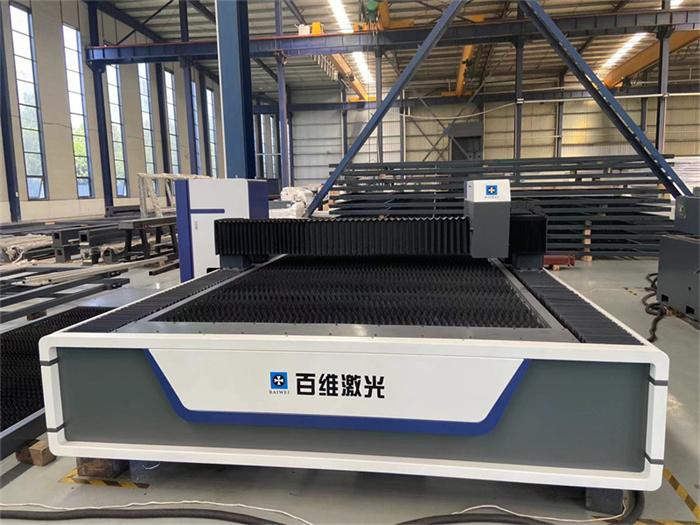

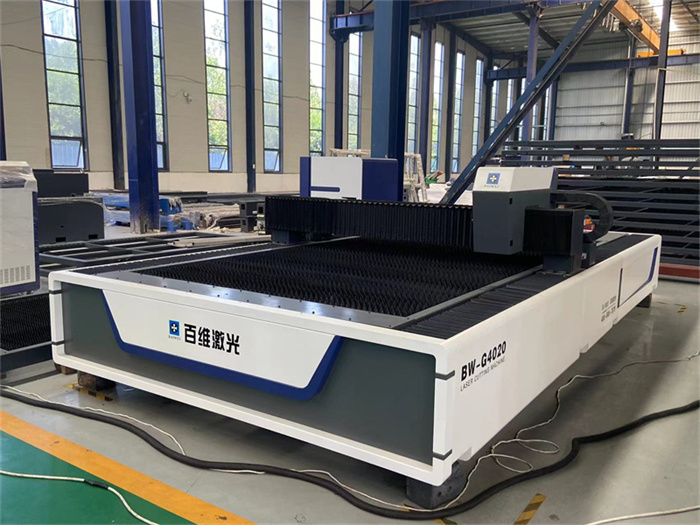

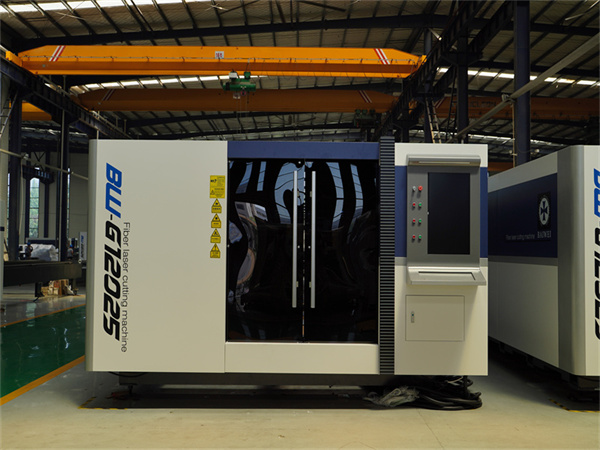

In the production process of hardware accessories, fiber laser cutting machine is needed, which has high cutting quality and fast speed.Model:BW-G4020

Laser Power:500w/1kw/2kw/4kw/6kw/8kw/10kw/12kw

Max.cutting Speed:35-80m/min

Positioning accuracy:0.03mm

Re-position accuracy:0.02mm

Min.line Width:0.1mm

High-performance bed, energy saving and environmental protection: The hollow bed designed for high power is adopted, and the stability of the machine tool is improved after multiple aging treatments. Time-sharing, partitioned, and segmented dust extraction structure, optional professional dust removal system, after the cutting waste gas and metal vapor are effectively discharged, the filtration degree is as high as 99.99%, making the working environment clean and hygienic.In the construction machinery industry, fiber laser cutting circular holes can be used as long as the diameter of the workpiece circular hole is greater than or equal to the plate thickness, and the roughness and diameter requirements are within the guaranteed capacity of the cutting machine when faced with a specific plate thickness. fiber laser cutting machine adopts CNC programming at all levels, which can process any plan, and can cut the whole plate with a large format without opening a mold, which is economical and time-saving. It can greatly improve our production efficiency. We adopt the design of heavy-duty gantry machine tools, aerospace-grade cast aluminum beams, and the equipment has good rigidity and stable performance. It can achieve high-speed handover of the workbench, simplify the work process and save time.