Industry Applications

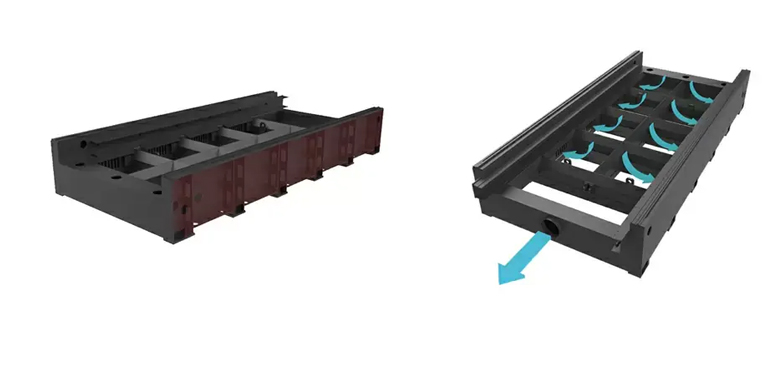

Baiwei BW Series fiber laser cutting machine as one classic model,widely used in manufacturing, such as sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts automobiles, engineering machinery, precision parts, ships, metallurgical equipment, elevators metal processing,and other manufacturing and processing industries.Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass aluminum, various alloy plate, rare metal and other metal materials.

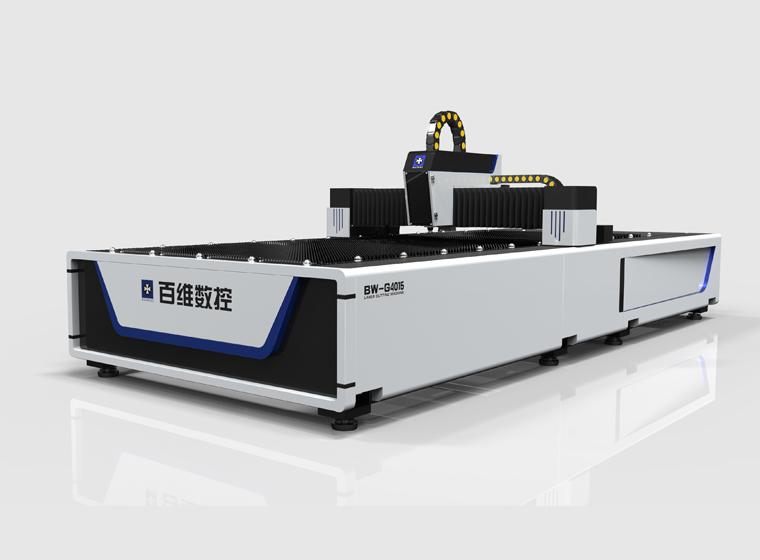

BW-G3015 3kw open type fiber laser cutting machine

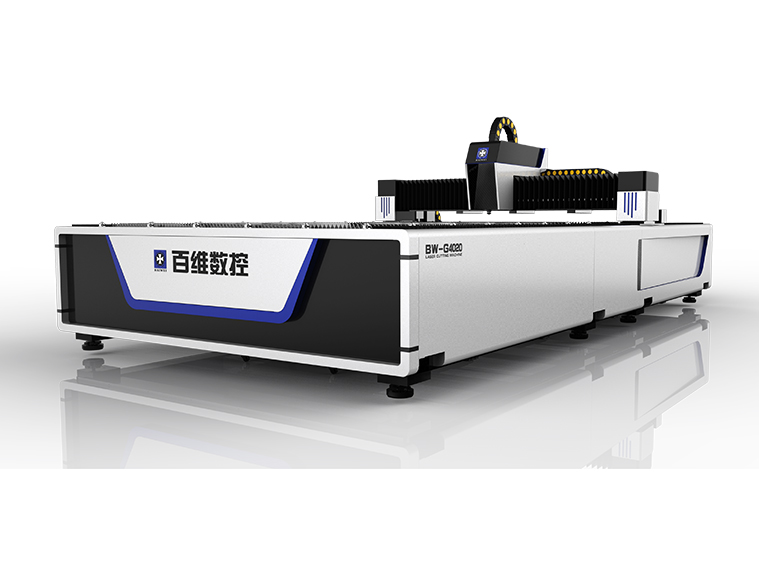

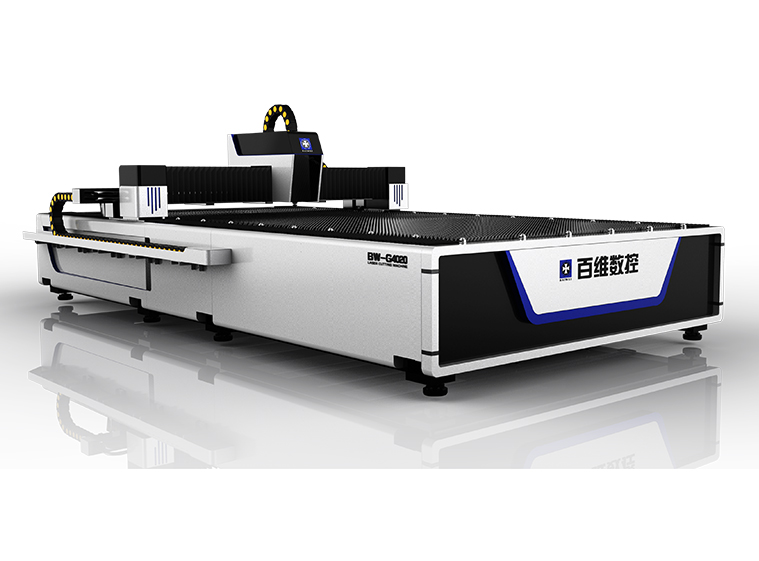

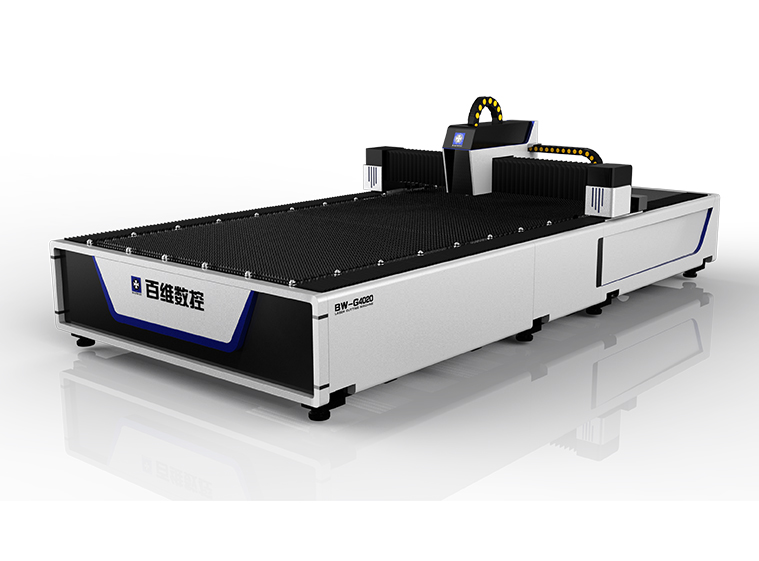

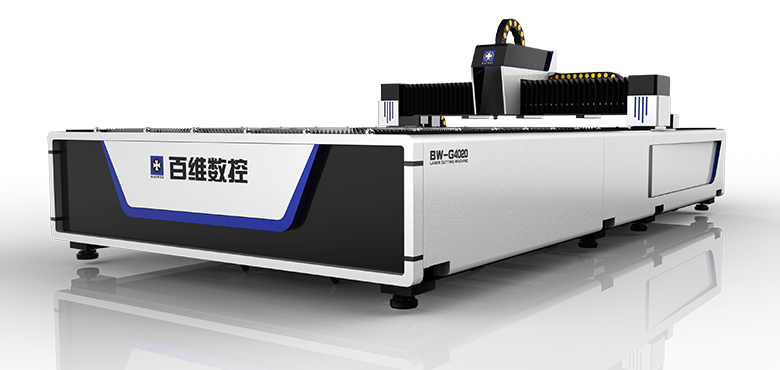

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

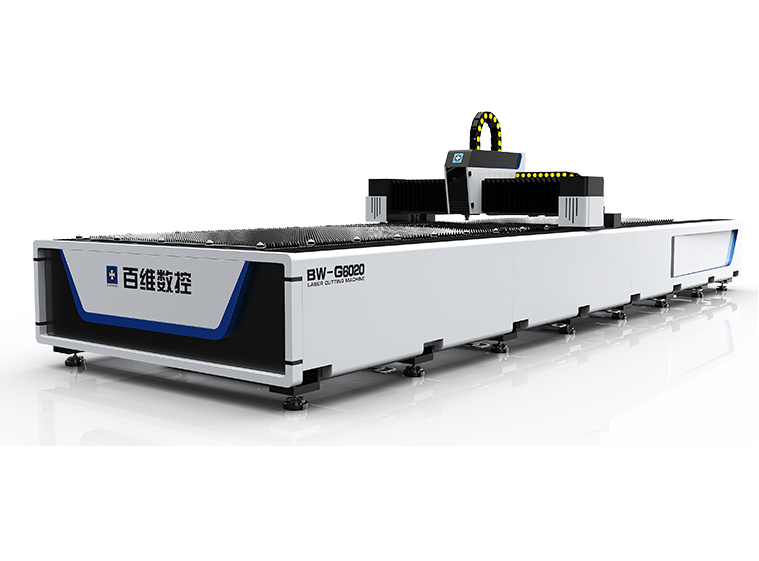

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

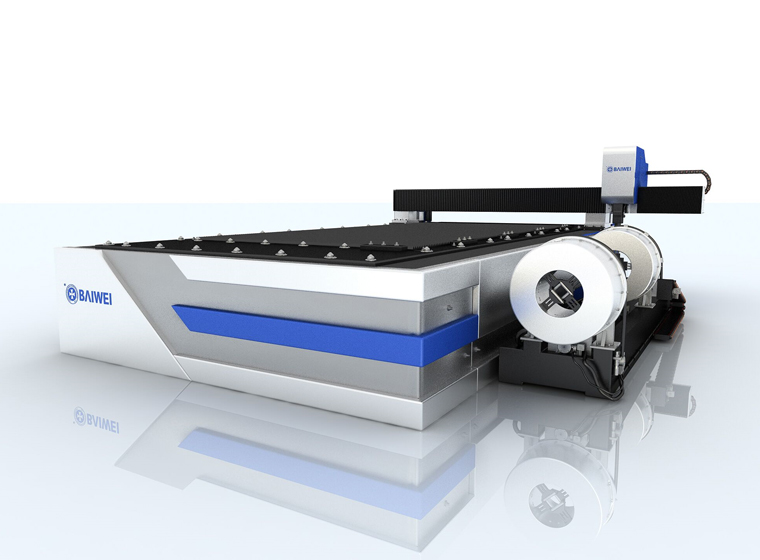

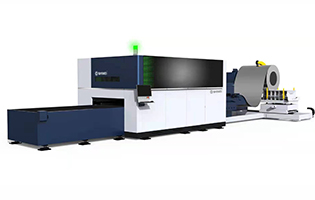

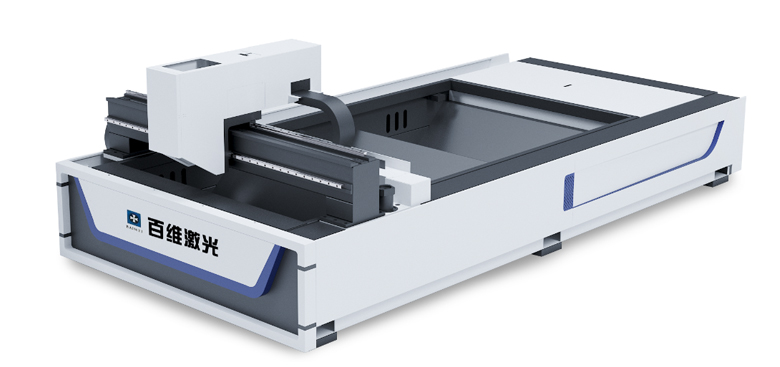

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

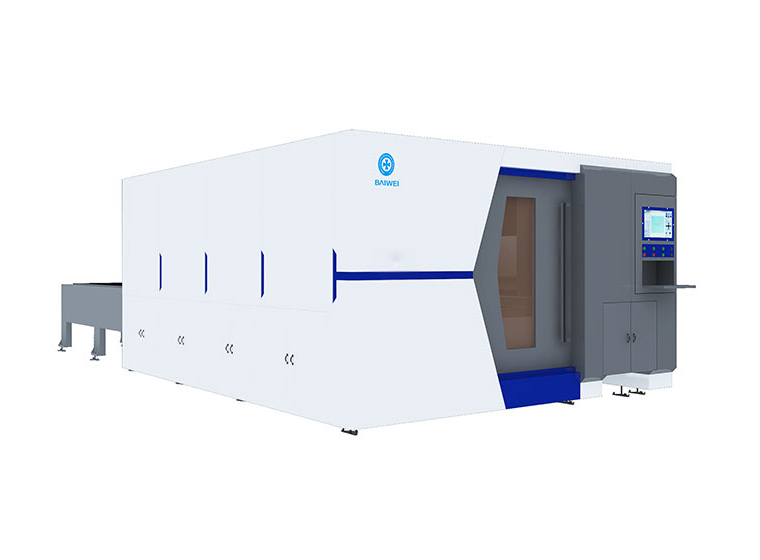

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

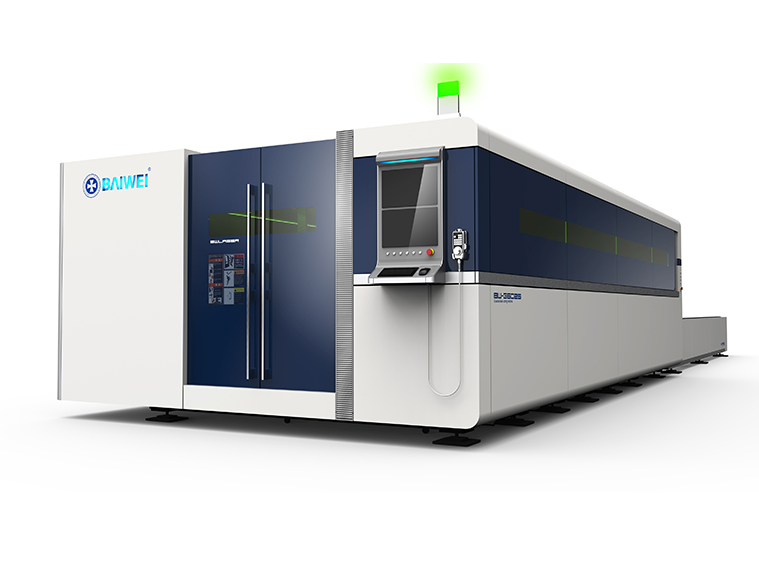

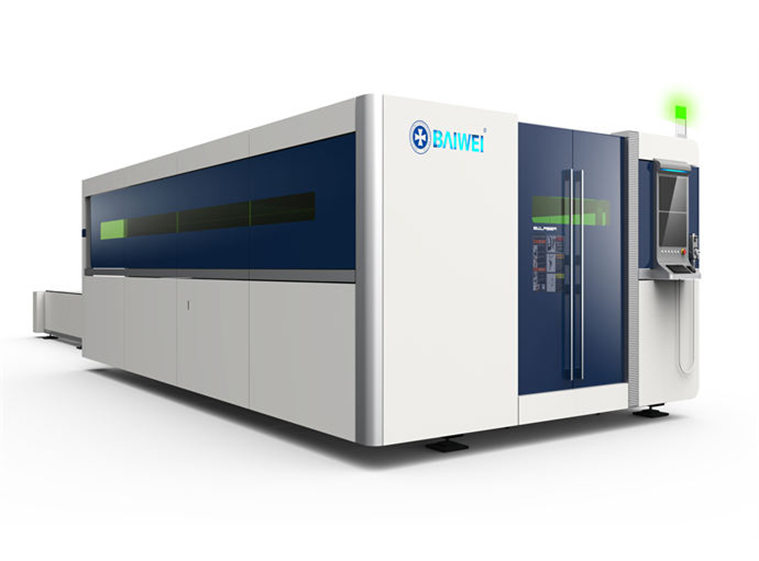

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

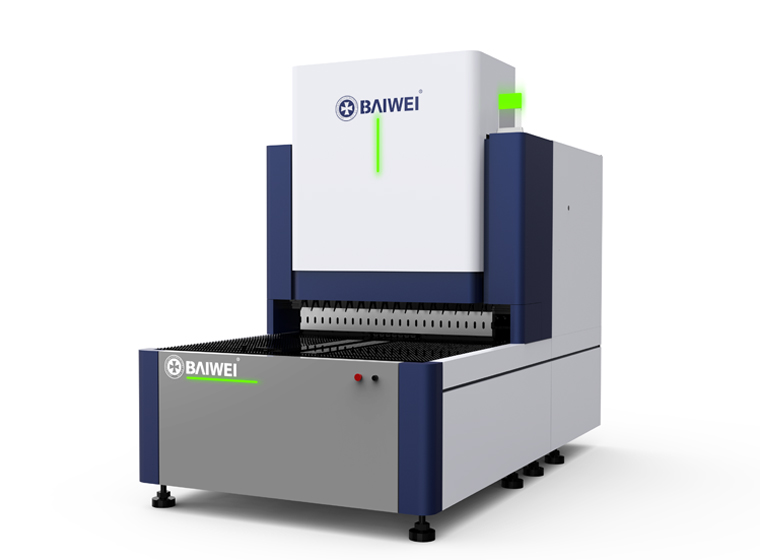

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.jpg)