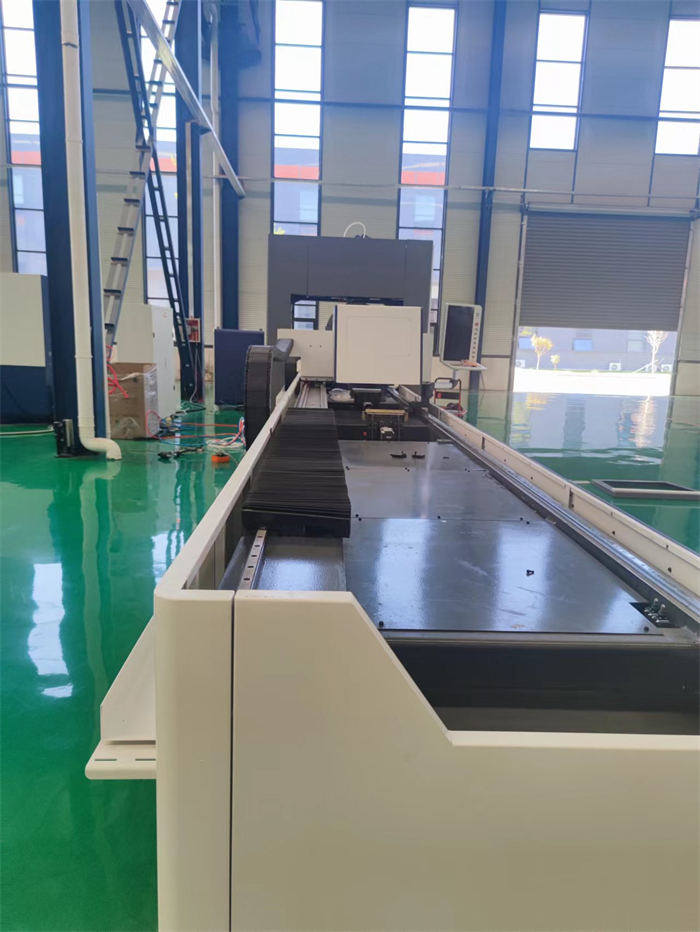

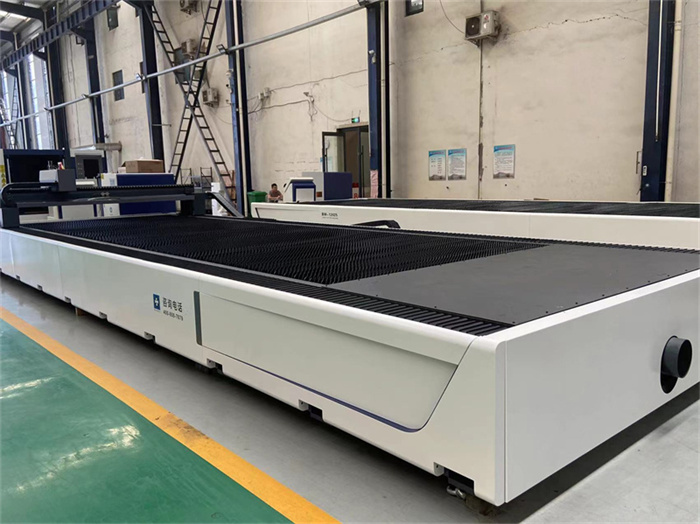

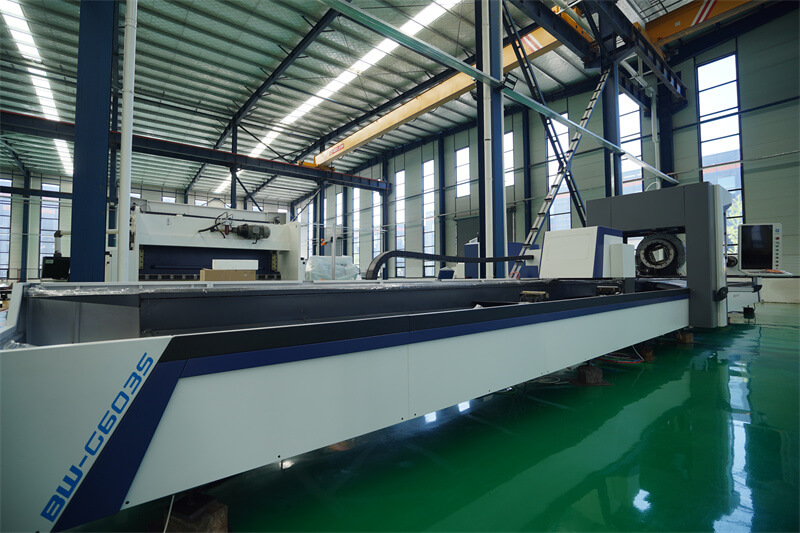

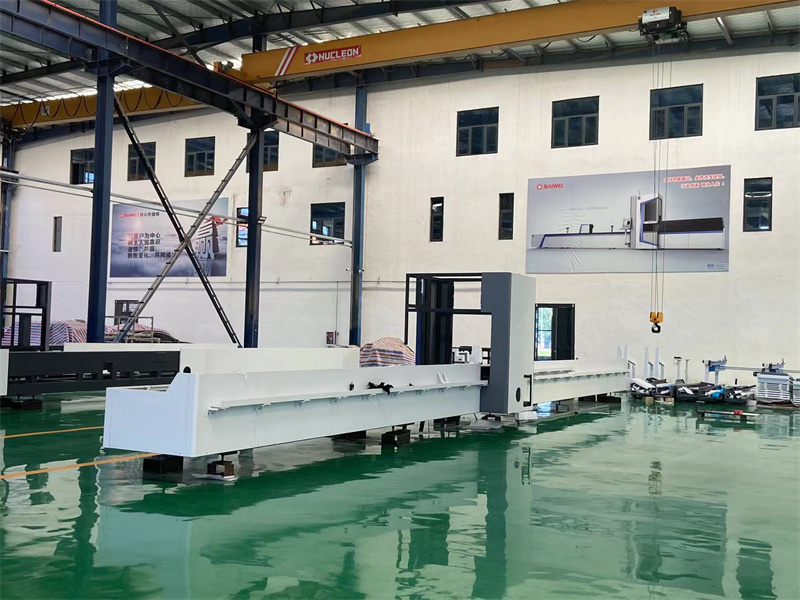

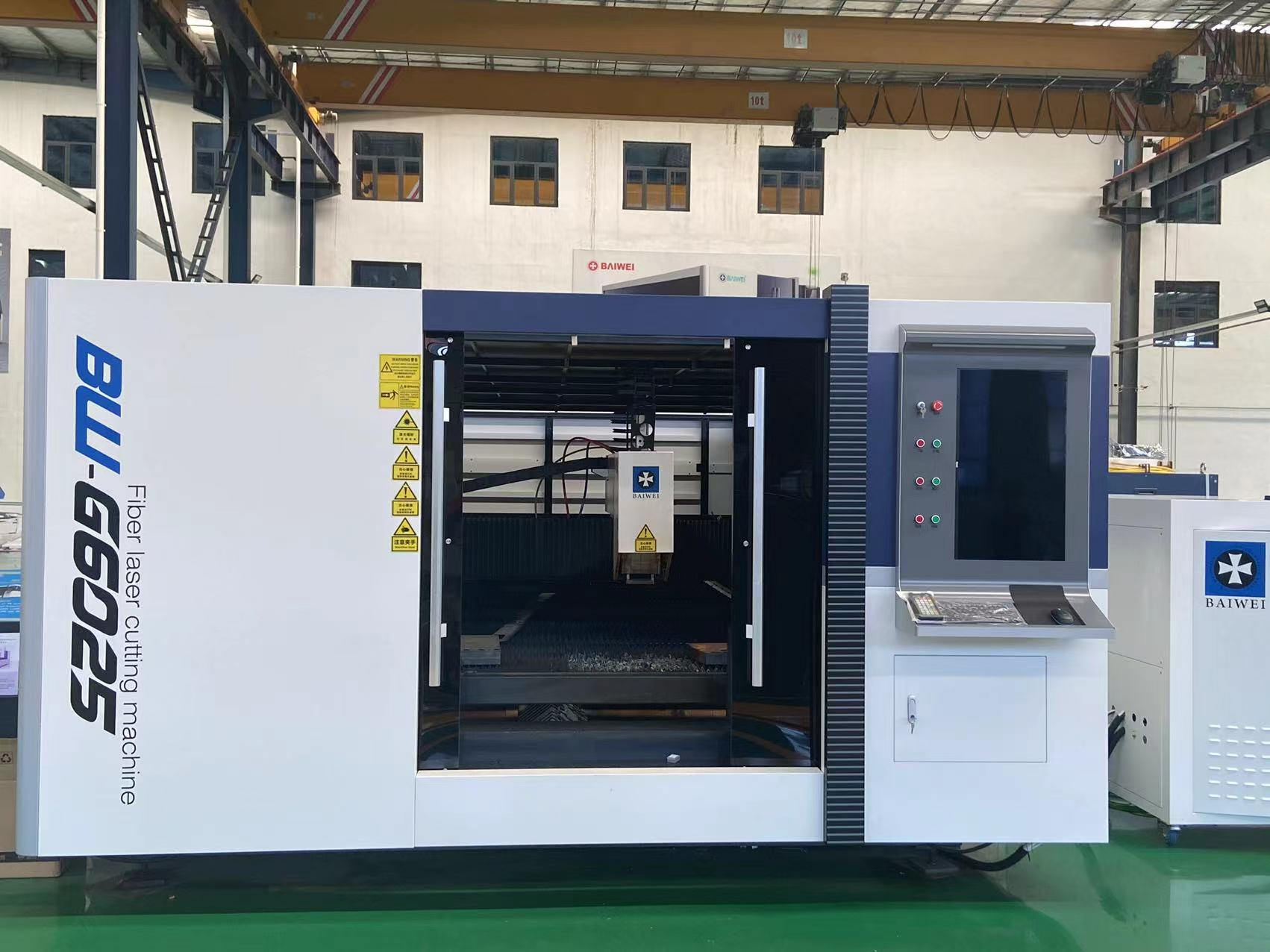

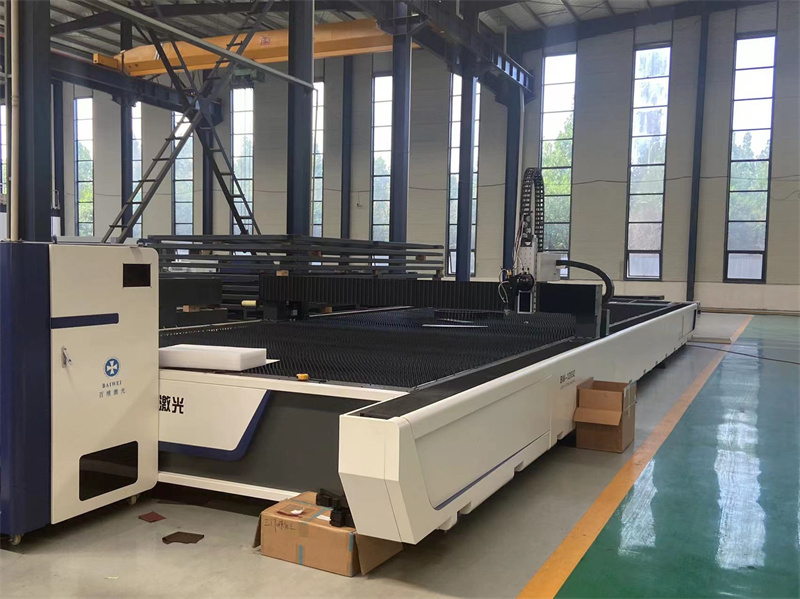

Easy-operated closed type fiber laser cutting machine for steel plate

The closed type fiber laser cutting machine adopts a closed cutting cabinet, and it is capable of precision cutting with small and medium power. Therefore, closed type fiber laser cutting machine reduces noise and operates safely.

Laser power:1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving:speed 100m/min

Max cutting:speed 35-80m/min

Positioning:accuracy 0.03mm

Repositioning accuracy:0.02mm

Min line width:0.1mm

How can I improve the efficiency of a laser cutting machine?

First of all, we need to pay attention to the maintenance problem, which is a key issue. If the laser cutting machine is properly maintained, the flexibility of operation will be greatly improved. When the capability of operation is improved, the efficiency of use can be increased naturally.

After that is to consider the inspection work before use, this work is very important, directly determines the use of the latter. We must check carefully. We should deal with the problems in time, and don’t neglect any details. Only after inspection can we avoid the problem of failure during the use period.

The last thing is to consider the failure during use. When we find fault, we need to shut down and deal with it in time. We must not think it’s a waste of time. If not processed, it will lead to greater failure, and the efficiency of the final use will definitely have a greater impact.