Home » Fiber Laser Cutting Machine » Laser cutting machine Large format ground rail type gantry laser cutting machine steel structure processing

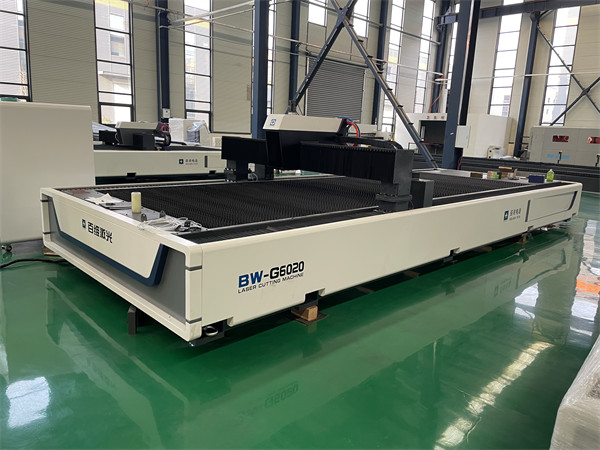

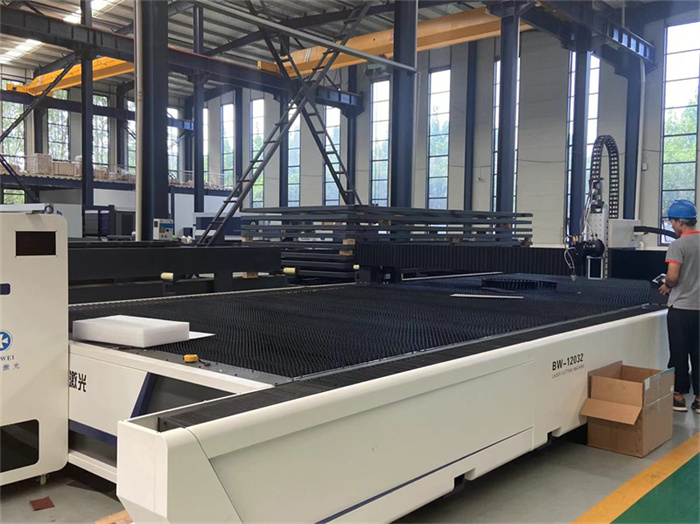

Laser cutting machine Large format ground rail type gantry laser cutting machine steel structure processing

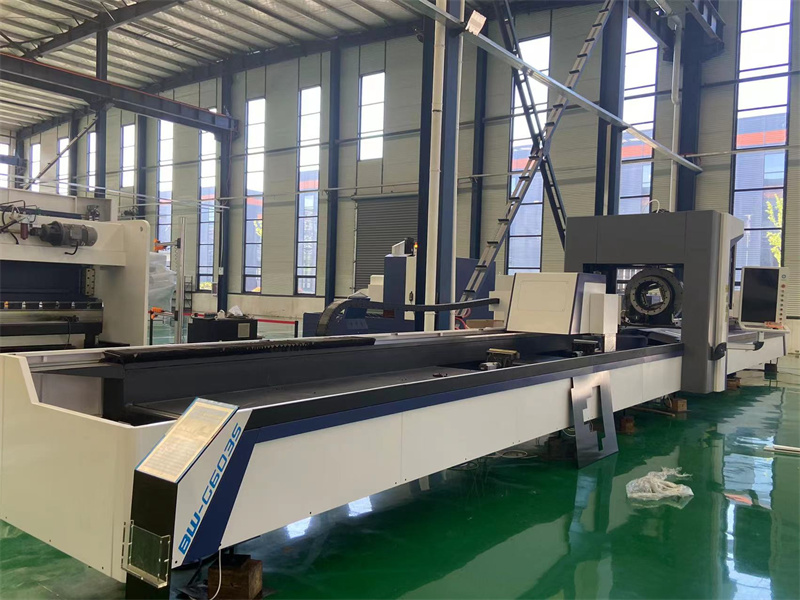

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

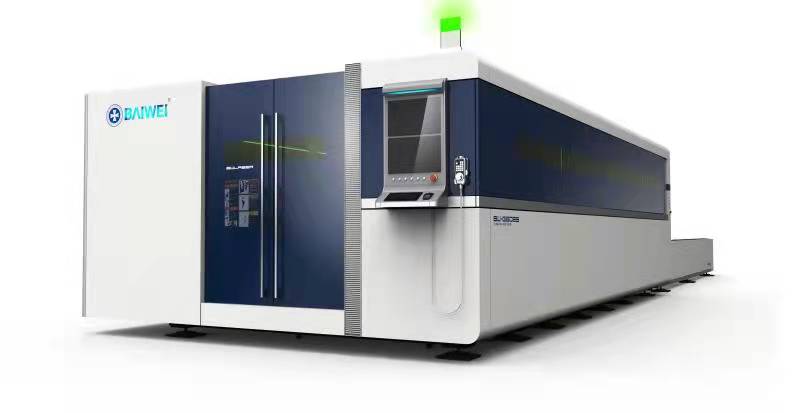

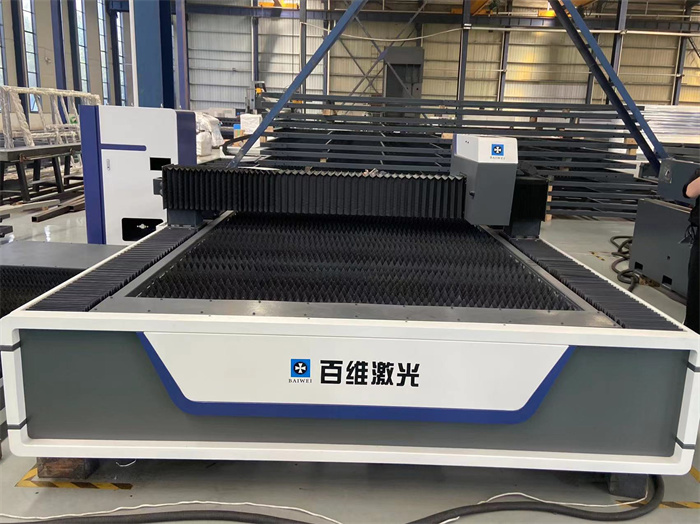

The enclosed fiber laser cutting machine is mainly used for fast cutting of carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling sheet, galvanized sheet, copper and other metal materials.

The overall outer surrounding structure can maintain good stability and safety for a long time; the automatic exchange table, the equipment can be loaded and unloaded while processing, which is convenient, fast and time-saving;

Both the servo motor hardware operation system and the software CNC system are imported from Germany, with good compatibility, strong stability, more convenient maintenance and more powerful cutting functions.

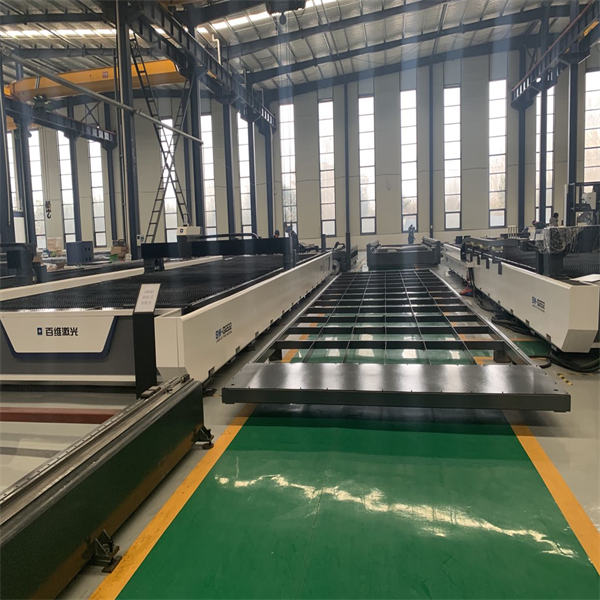

Excellent beam quality: smaller focusing spot, higher work efficiency and better processing quality; extremely high cutting speed: 2 times that of the same power CO2 laser cutting machine;

Extremely high stability: The world’s top imported fiber lasers are used, with stable performance, and the service life of key components can reach 100,000 hours; extremely high electro-optical conversion efficiency: fiber laser cutting machine is 3 times higher than CO2 laser cutting electro-optical conversion efficiency, Energy saving and environmental protection;

Extremely low cost of use: the power consumption of the whole machine is only 20-30% of that of similar CO2 laser cutting machines. Extremely low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective mirrors, which can save a lot of maintenance costs;

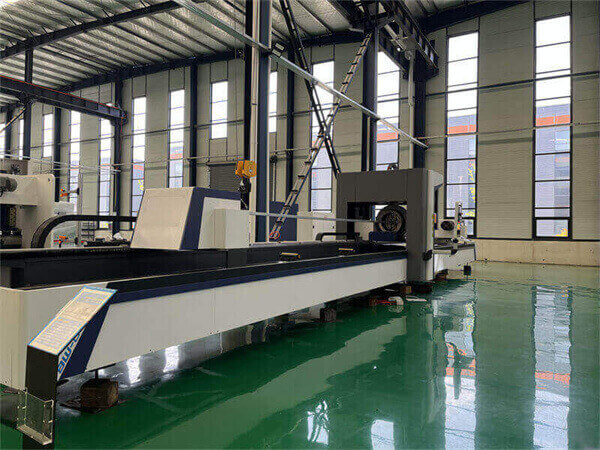

The product is easy to operate and maintain: optical fiber transmission, no need to adjust the optical path. Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements.

The fully enclosed design provides personal safety protection from invisible laser radiation and mechanical movement of the machine tool. The world’s top fiber lasers and electronic components are used to ensure the super stability of the equipment

High-speed cutting, dozens of meters per minute, higher cutting efficiency. Independent control cabinet, dust-proof isolation, improve the life of electronic components;

The whole machine adopts a large encircling design to protect the safety of the operators; the craft bed, with reinforcing ribs in the middle of the bed, improves the service life of the bed.

Prevent dust leakage caused by cutting and ensure the cleanliness of the work area. Avoid laser pollution, protect the safety of operators in the production process, and improve the safety factor

Extend the service life of the machine, maintain and improve the quality of product processing, and finally achieve stable and high efficiency.

Inquiry

More Fiber Laser Cutting Machine