Home » Fiber Laser Cutting Machine » Fiber Laser Cutting Machine Laser Manufacturing Expert Save Time and Double Production Capacity

Fiber Laser Cutting Machine Laser Manufacturing Expert Save Time and Double Production Capacity

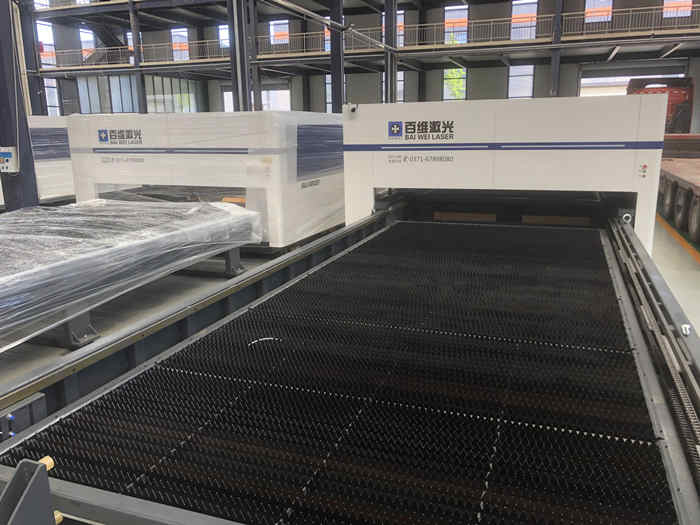

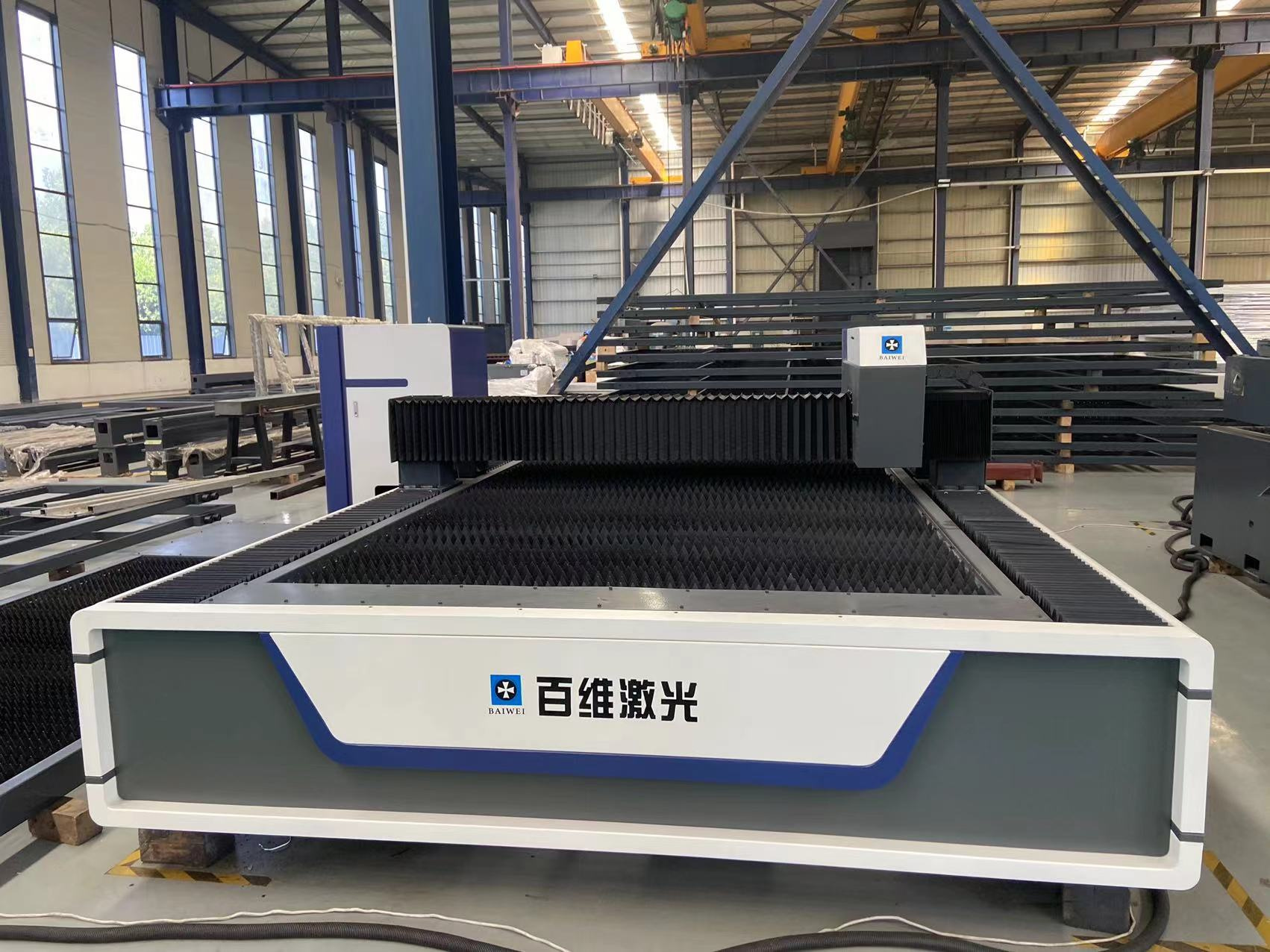

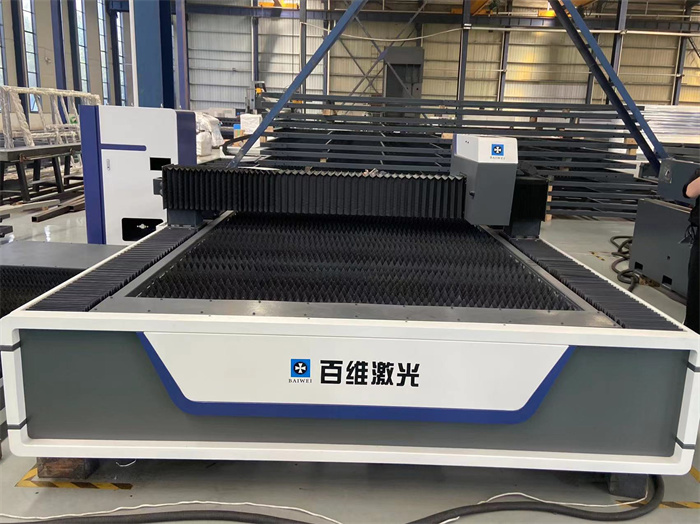

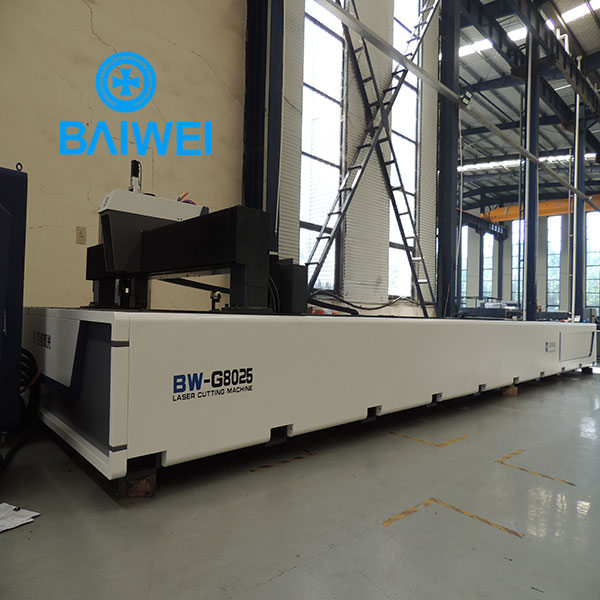

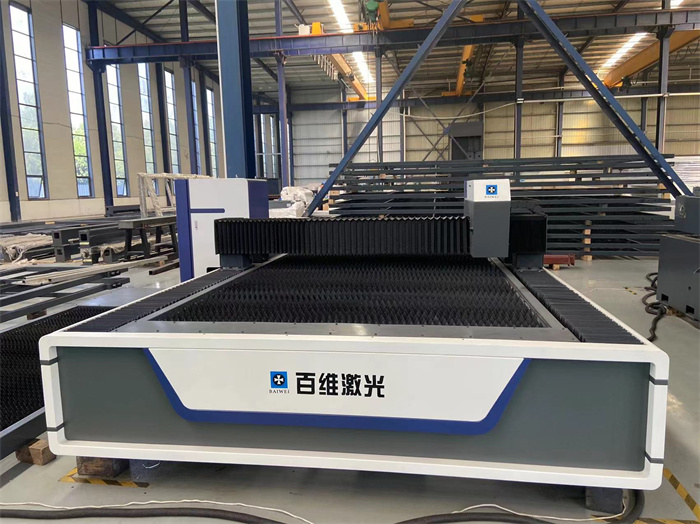

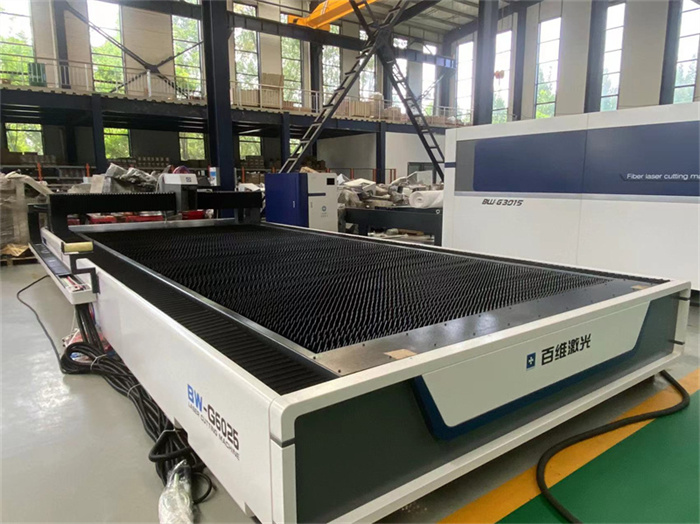

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

Advertising metal word industry

Advertising traditional processing equipment generally uses materials such as processing advertising fonts. Due to the unsatisfactory processing accuracy and cutting surface, the probability of rework is quite large. The high-precision laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

Sheet metal processing industry

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the requirements of current technology and cutting shape. Laser cutting has gradually replaced traditional equipment with the advantages of high flexibility and fast cutting speed. Fiber laser cutting machine Widespread application in sheet metal processing is an inevitable trend.

Chassis and Cabinet Industry

The power distribution cabinets, file cabinets, etc. we see in our lives are all products produced by standardization of thin plates, and have high requirements for efficiency. Using a laser cutting machine with four or six stations is relatively suitable and has high efficiency at the same time. , it can also achieve double-layer cutting for specific plates.

Agricultural machinery industry

With the continuous development of agriculture, the types of agricultural machinery products tend to be diversified and specialized, and at the same time, new requirements are put forward for the manufacture of agricultural machinery products. The advanced laser processing technology, drawing system and numerical control technology of the laser cutting machine not only reduce the production cost of agricultural machinery and equipment, but also improve the economic benefits.

shipbuilding industry

In the field of shipbuilding, the marine steel plate cut by laser has good kerf quality, good verticality of the incision surface, no slag, thin oxide layer, smooth surface, no need for secondary processing, direct welding, and small thermal deformation, curve cutting High precision, reduce working hours, and achieve barrier-free cutting of high-strength ship plates.

Sheet metal processing industry

Laser cutting can be described as a major change in sheet metal processing. Due to the high level of flexibility of laser cutting, fast cutting speed, high cutting efficiency, and short product work cycle, it immediately became the darling of the sheet metal processing industry. Laser cutting has no cutting Force, no deformation during processing; no tool wear, no matter what kind of parts, it can be cut by laser in one fine and rapid prototyping. In addition, laser cutting slits are often narrow, and the cutting quality is good, the automation level is high, the labor intensity is low, and there is no pollution. When processing accessory cabinets and file cabinets, it is often the standardized production of thin plates. Using a laser cutting machine for cutting processing is more efficient and faster to complete the cutting processing requirements.

Inquiry

More Fiber Laser Cutting Machine