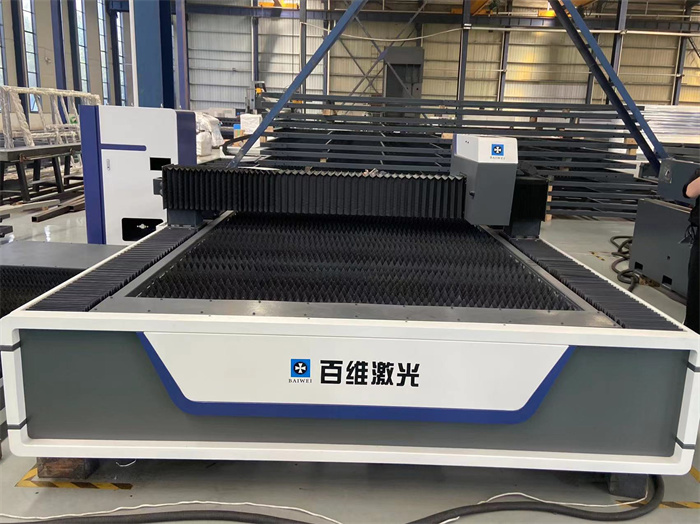

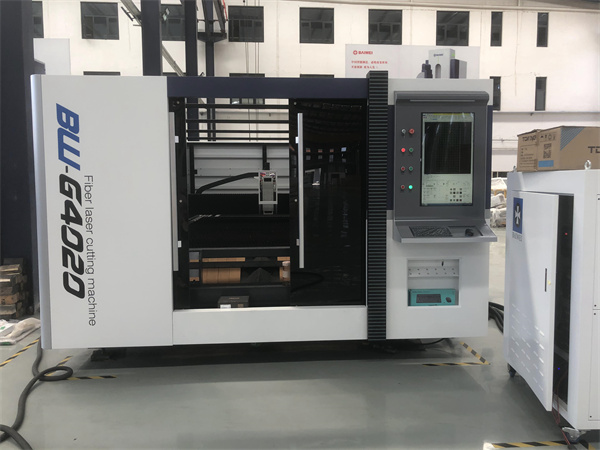

Intelligent closed fiber laser cutting machine for sale industrial

The enclosed fiber laser cutting machine adopts an automatic exchange table, and the equipment can be loaded and unloaded while processing, which is convenient, fast and time-saving. The enclosed fiber laser cutting machine is mainly used for fast cutting of carbon steel, silicon steel, stainless steel and other metal materials.

Laser Power:12kw/15kw/20kw/30kw (Optional)

Laser Source:IPG/Nlight/Raycus

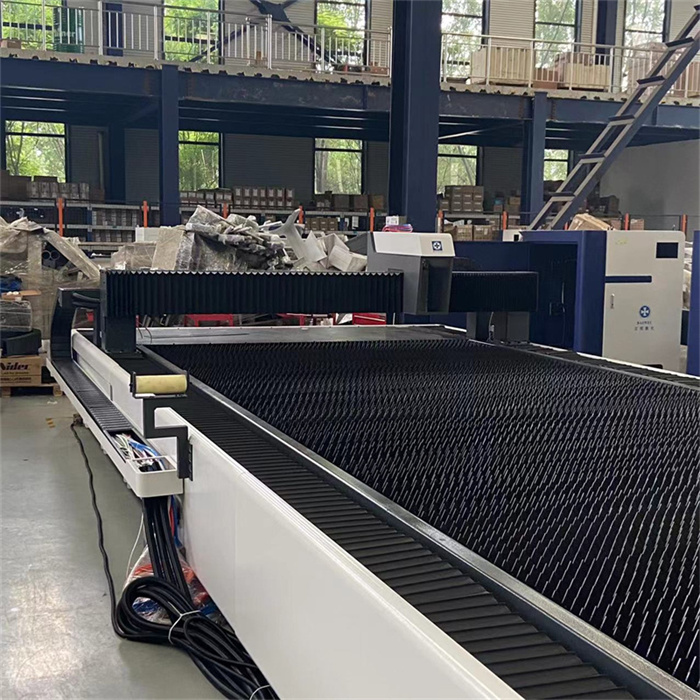

Processing Surface (L*W):13500*3200mm/13500*2500mm/12500*3200mm/12500*2500mm/10000*3200mm (Optional)

Position Accuracy X, Y and Z Axle:+0.03MM

Cutting Thickness:Carbon Steel 0.5MM-40MM, Stainless Steel 0.5MM-40MM

Which laser is most widely used for laser cutting?

Since the start of fiber lasers now fiber lasers are normally used for industrial laser cutting machines. Now it is possible to say that all preliminary actions are done, manufacturers and companies have the proper adjustment of their sources to make good and clean cuts and there are lot of new names and competitors who started to make and offer laser cutting machines with fiber source.

CO2 laser has the complicated equipment for travelling of beam which is generally eliminated with fiber laser. For example CO2 laser route had tubes, several lenses and everything needs to be properly adjusted, cleaned and stay in the perfect condition. To adjust the fiber laser source is much much complicated and cheaper and that is why companies started to make just the tables and the main control to get the source from the other supplier. With CO2 lasers it was quite hard and table was connected with the source so there were not too much companies to offer laser cutting machine because usually they are developers and manufacturers of CO2 sources.

So fiber is new era and you can get proof at any industrial exhibition. Moreover the top-brands in laser cutting machines started to offer fiber laser machines. Sorry I’m not the best specialist so maybe terminology is not perfect.