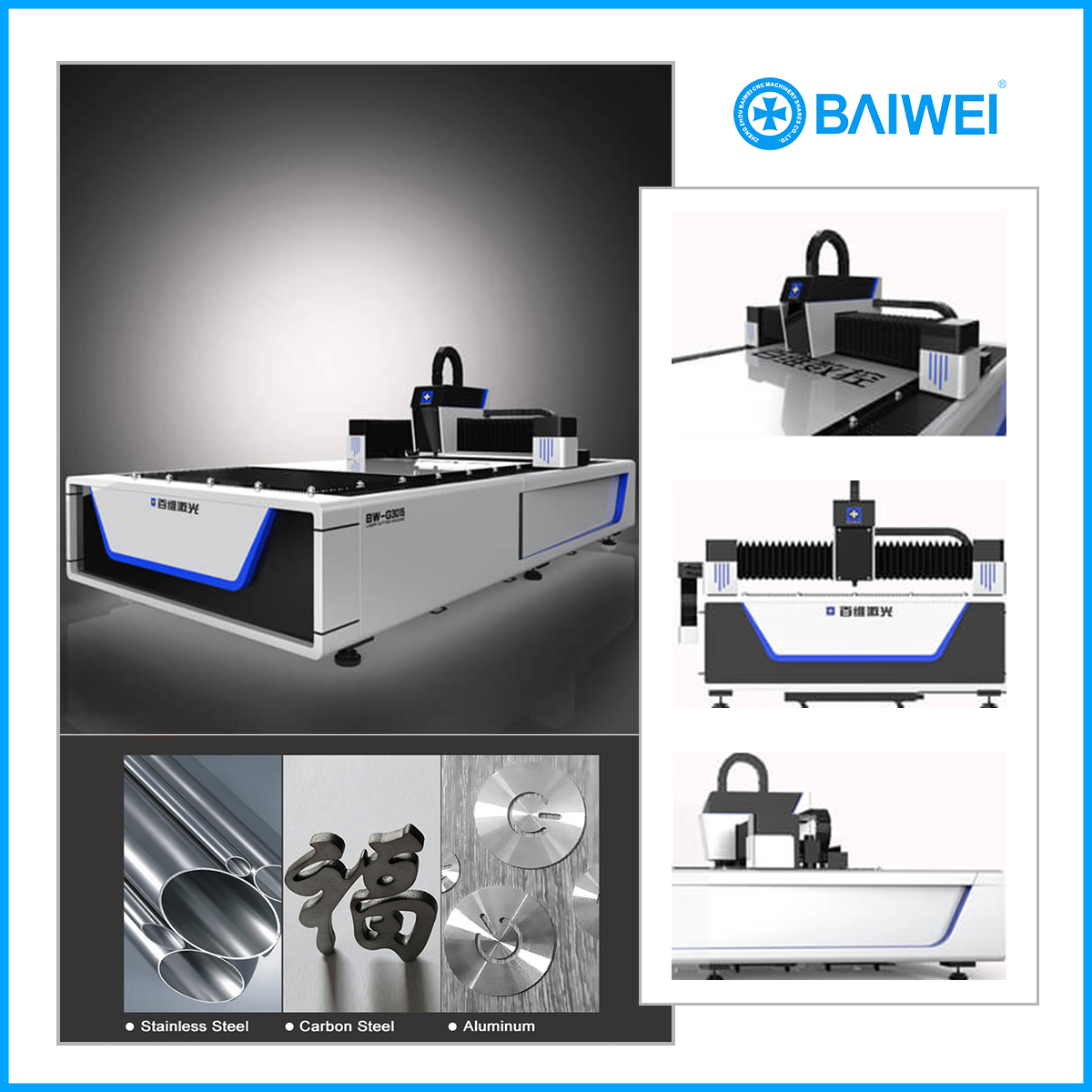

square and round tube laser cutting machine stainless steel tube machine

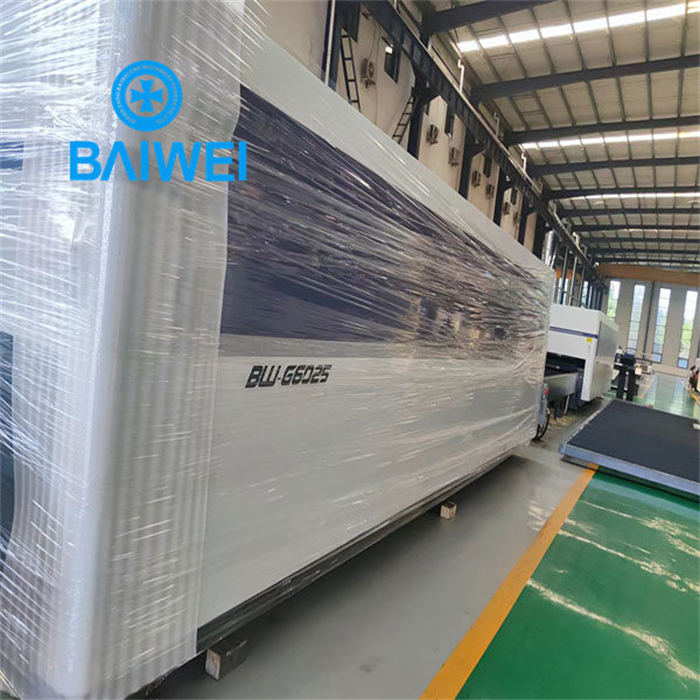

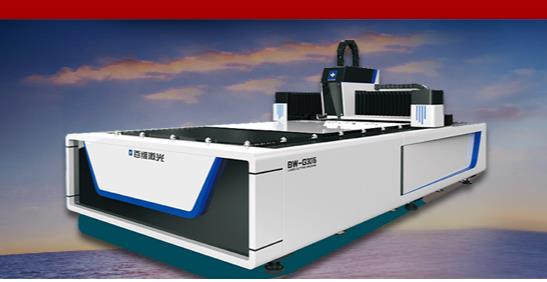

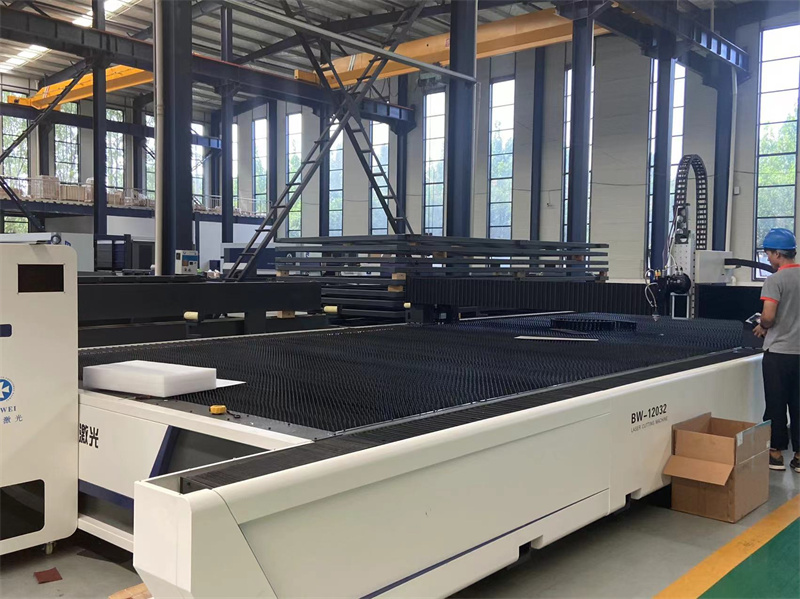

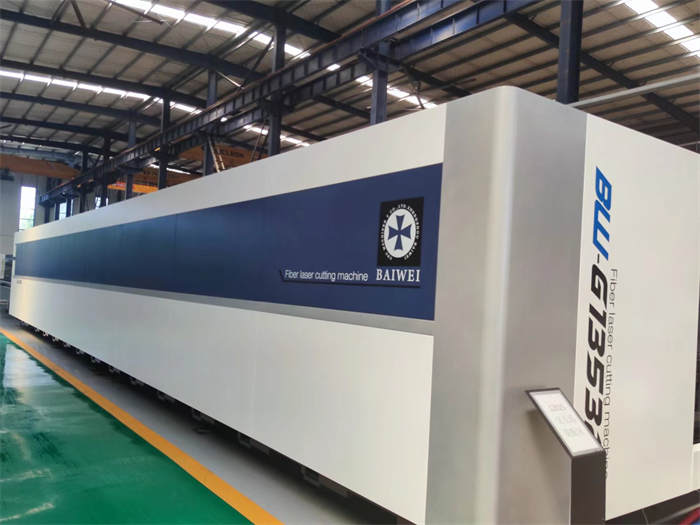

Model:BWQG6016-6000*160 professional tube laser cutting machine

Power:3kw/4kw/6kw/8kw

Cutting diameter: ≤499mm

Cutting length: 6000mm/9000mm/12000mm

What are the advantages and characteristics of fiber laser cutting compared to traditional cutting?

In comparison with the traditional cutting method—-plasma cutting machine. There are two advantages of fiber laser cutting machine: cutting precision and running cost.

Plasma cutting machine is widely applied in the thick metal sheet with low cost, but the cutting surface is very rough for the sake of low precision of compensation. The key part of a plasma cutting machine is the power supply, because it utilizes the high temperature to melt partial surface of metal material.

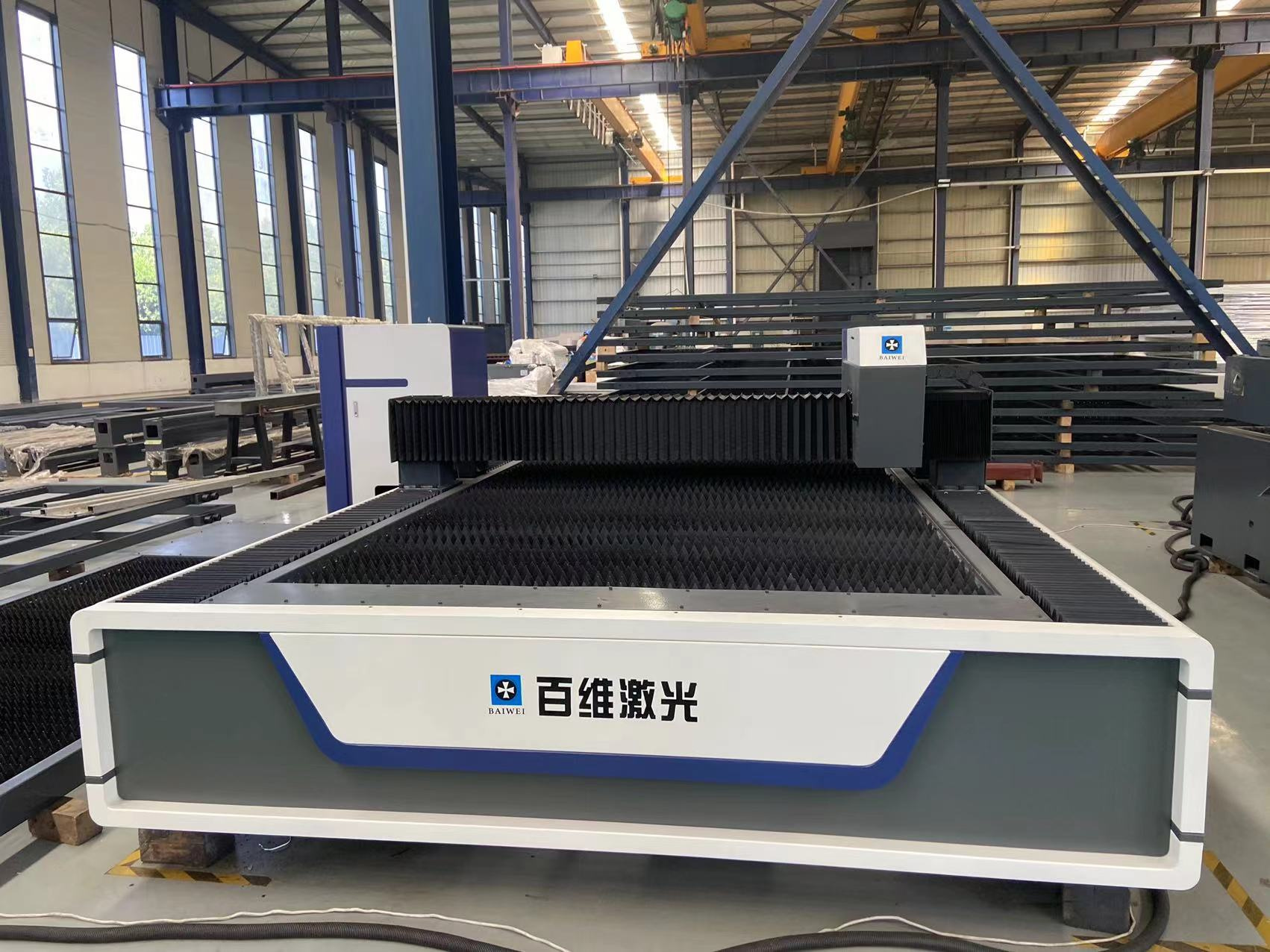

While fiber laser cutting machine makes full use of laser beam to heat the material within short time, and the sludge would be removed by the high pressure air. The smooth cutting surface and narrow seam are made by the non-contact laser beam, so a fiber laser cutting machine could improve the cutting effect and emit the cost of second processing.

Due to the concentrated laser beam, fiber laser cutting machine is mainly applied in the thin metal sheet, it could guarantee small heat influenced zone and small cutting seam.