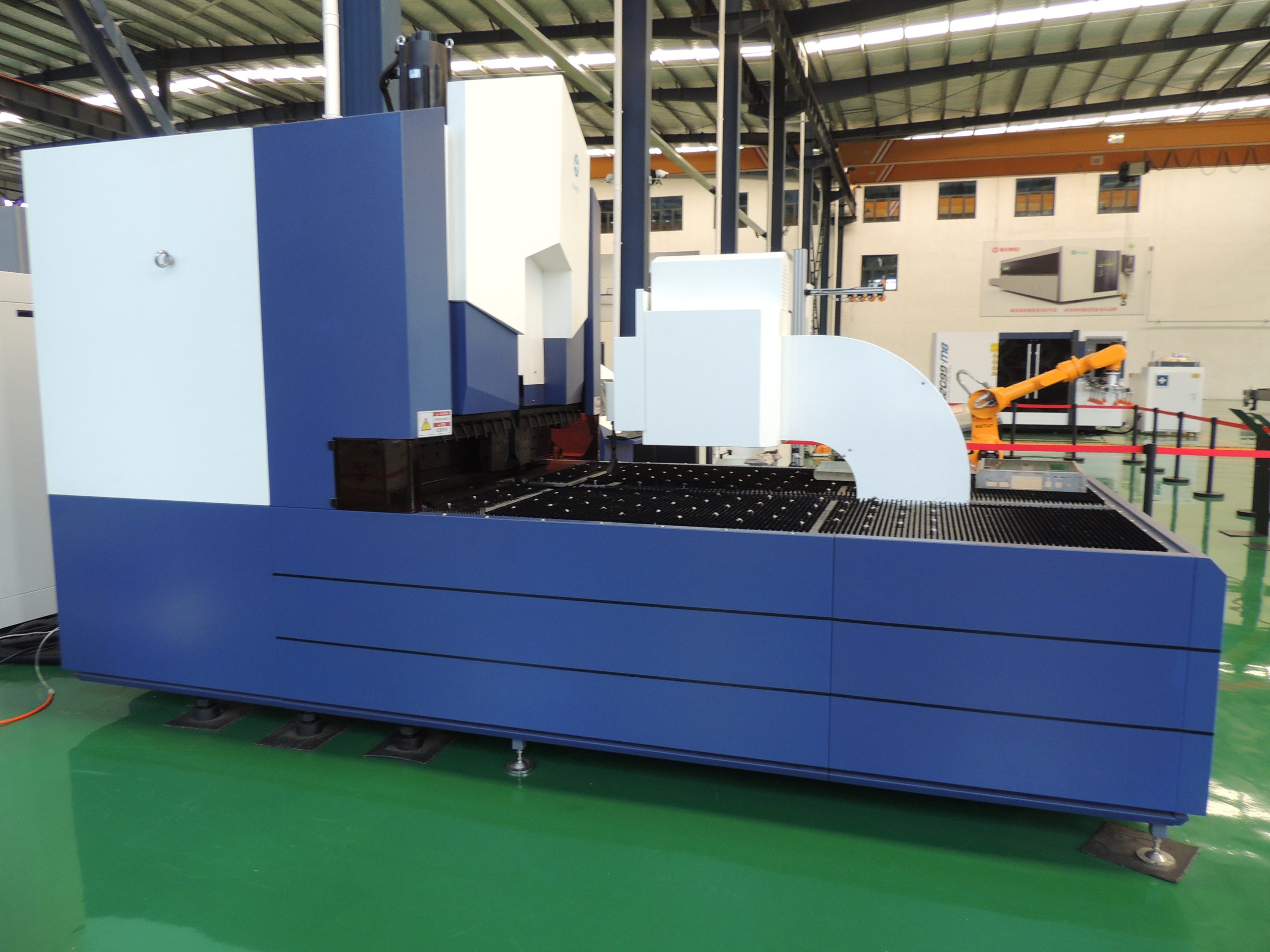

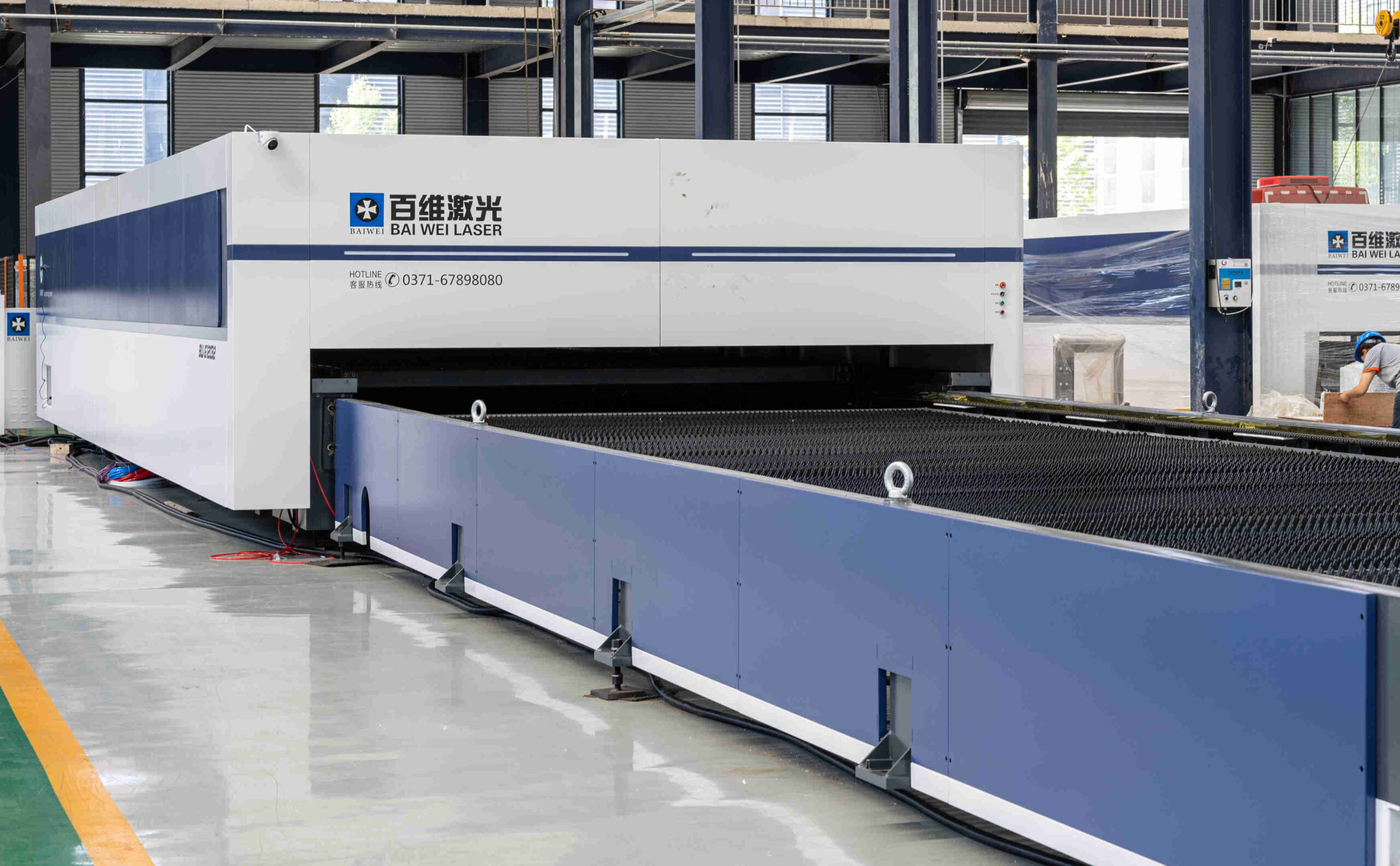

Baiwei laser sheet metal servo flexible bending center machine

Maximum bending speed: 0.2 second/shot

Maximum bending width: 1400mm

Bending height:About 170mm(customizable)

The rated voltage:380V

Peak power:about 18KW

Average power:about 1.8KW

The noise:about 50 decibels

Dimensions:440cm*190cm*290cm

The total quality:about12tons

Maximum beding thicknessUTS 515N/mm2 201stainless steel 0.8mm

(standard) UTS 520N/mm2 304stainless steel 1.0mm

(Optional thickness) UTS 410N/mm2 304cold plate 1.2mm

UTS 265N/mm2 304Aluminum plate 1.6mm

Minimum material thickness:about0.35mm

Minimum inner dimensions:about140mm*190mm

Minimum inner size:about140mm

Minimum bending size:about1400mm*1400mm

Number of shaf:standard 13axis concurrent linkage

Conventional hinge cutter:(option)

Power hinge cutter:(option)

What are the advantages of the sheet metal servo flexible bending center machine?

sheet metal Automatic servo flexible bending center enables users to effectively handle large quantities, and even improve efficiency without making mistakes.

Hydraulic servo bending center

The sheet metal processing industry is under pressure: it must maintain low production costs without compromising quality.

At the same time, continuous changes in shape, size, and batch size require a higher degree of flexibility. Companies that want to remain competitive must increase process flexibility and, most importantly, they must also automate.

Automatic bending center

The fully automatic sheet metal bending unit provides the maximum efficiency and flexibility for small and large manufacturing companies.

The modular design allows the bending unit to be individually adapted to the company’s requirements. It is very suitable for processing long work lists and also for changing orders: from small batches to large batches.