High degree of automation, easy operation and strong compatibility

Industry 4.0 architecture, which can be upgraded smoothly;

No molding required, complex shapes (folded up or down right angles, non-right angles)

Free design and production at any time;

Wide range of applicable materials, mainly stainless steel, cold-rolled plate, etc.;

Compatible with various loading and unloading methods: manual loading and unloading, self-driven robotic arm loading and √unloading, and docking robotic arm loading and unloading are all optional.

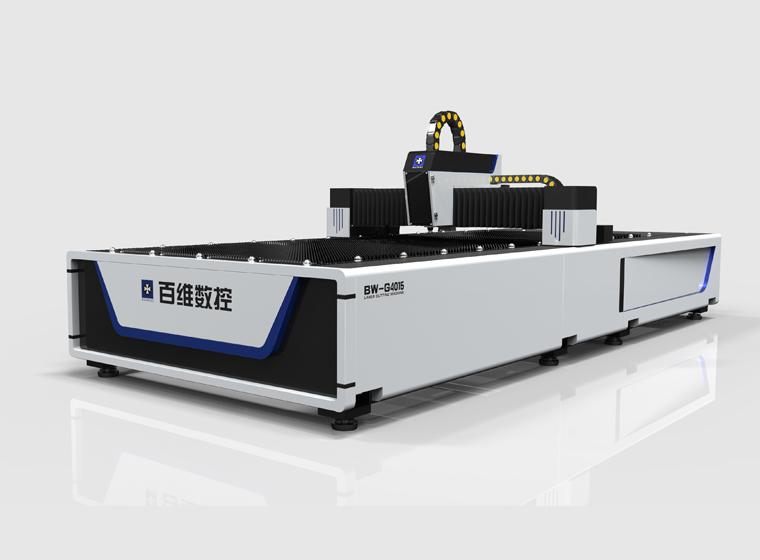

BW-G3015 3kw open type fiber laser cutting machine

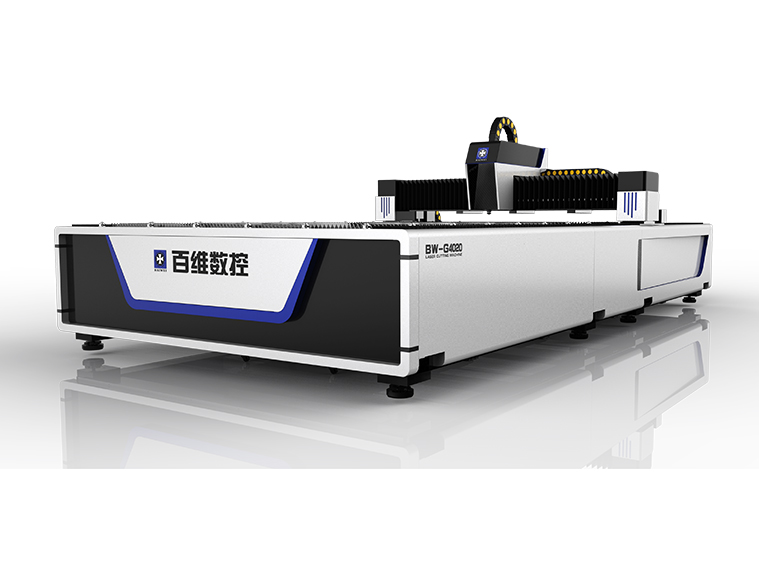

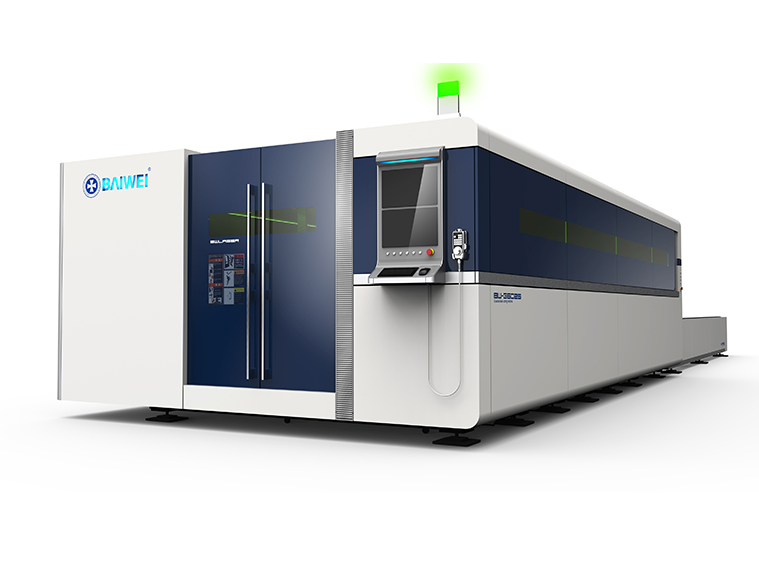

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

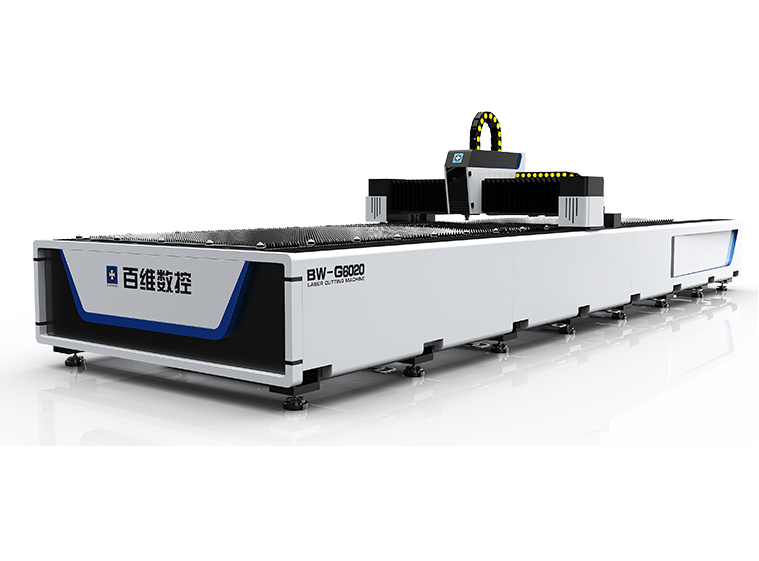

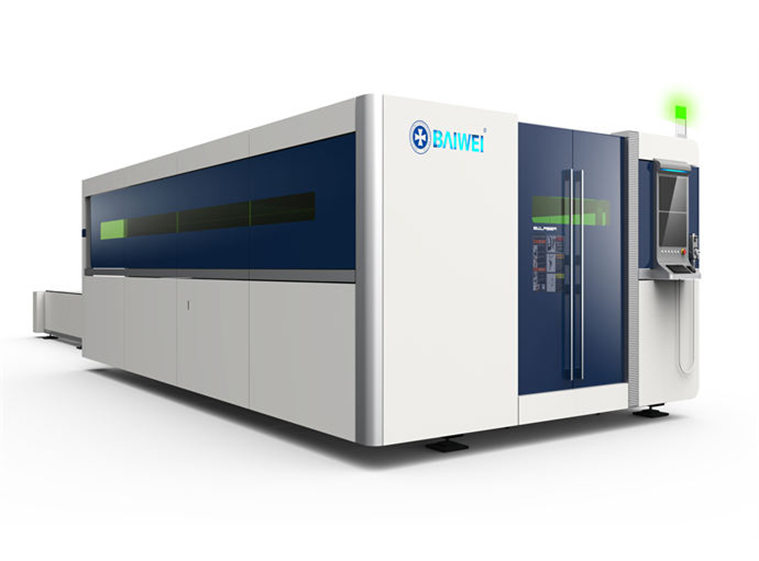

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

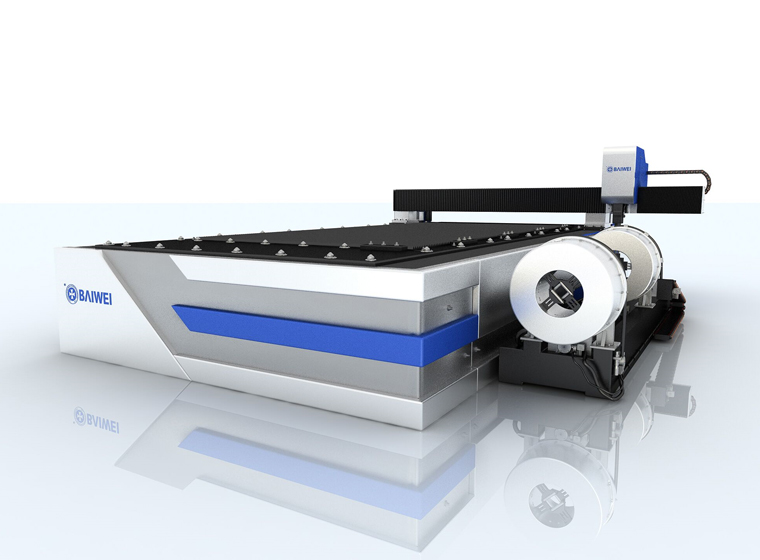

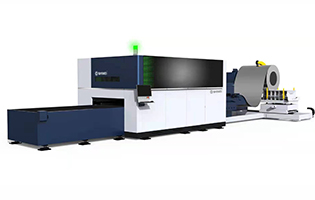

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

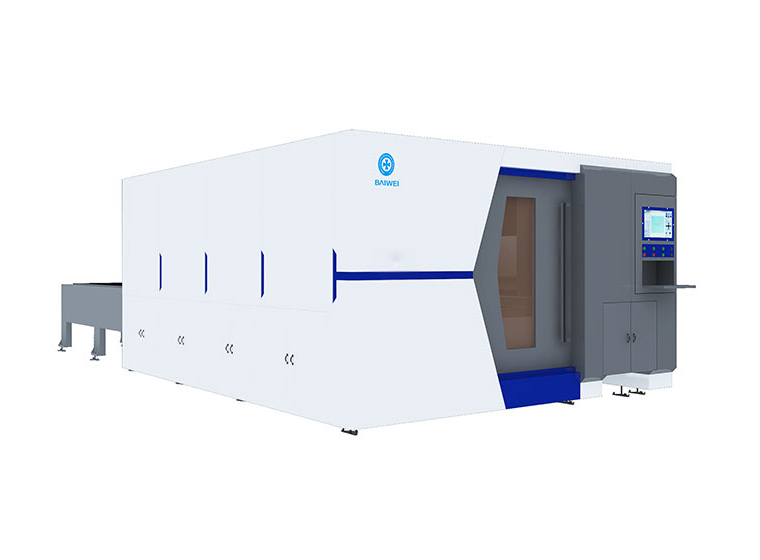

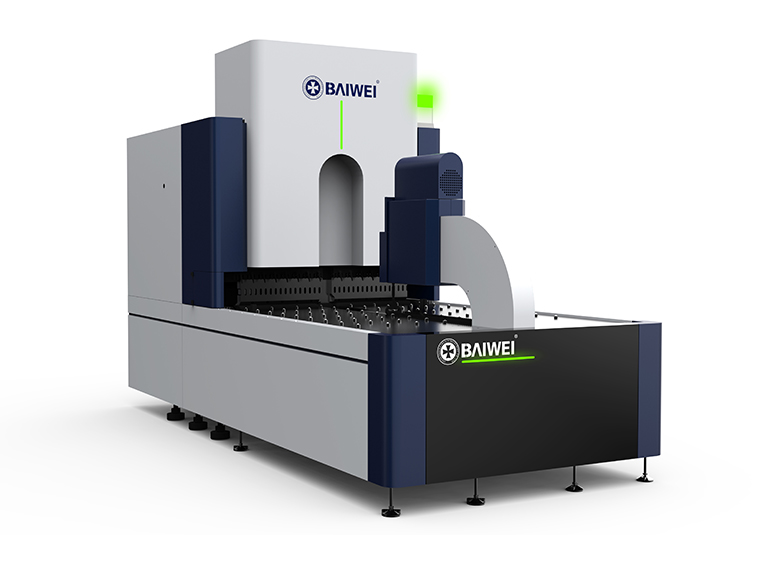

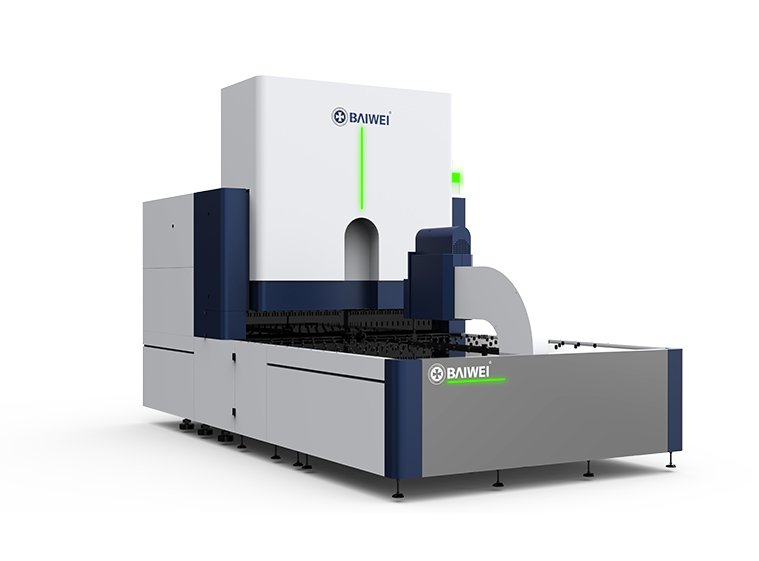

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

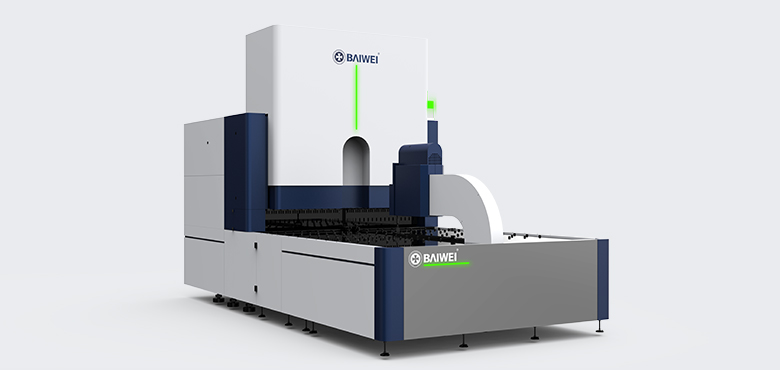

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

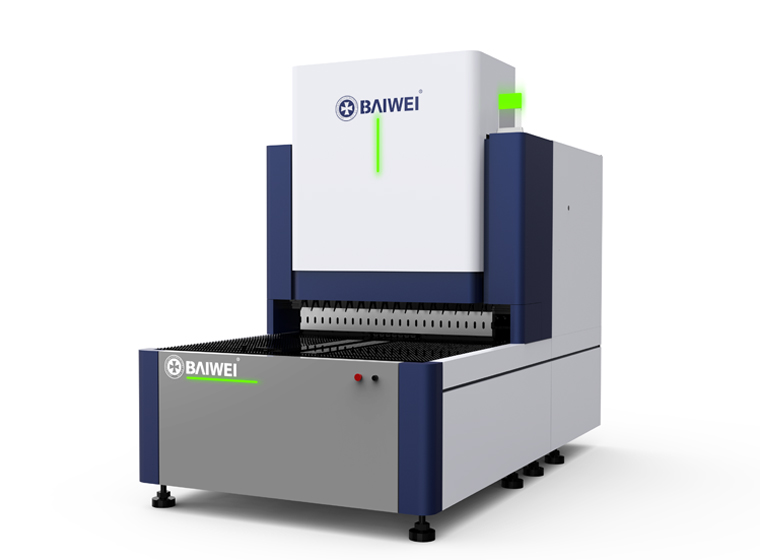

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.jpg)