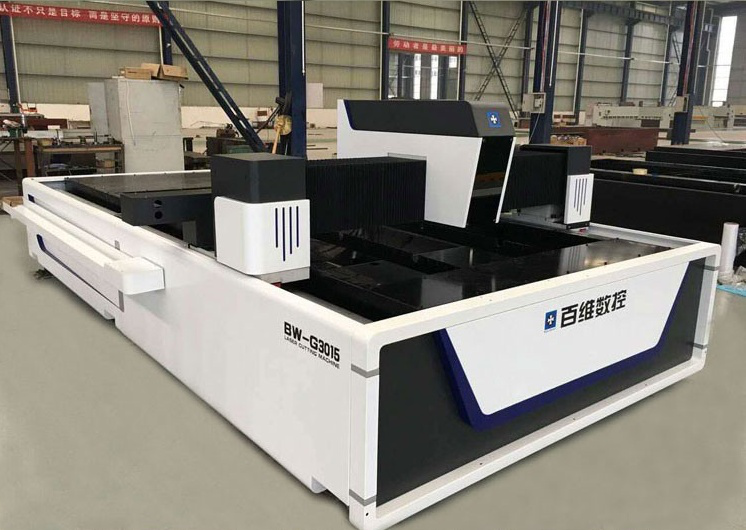

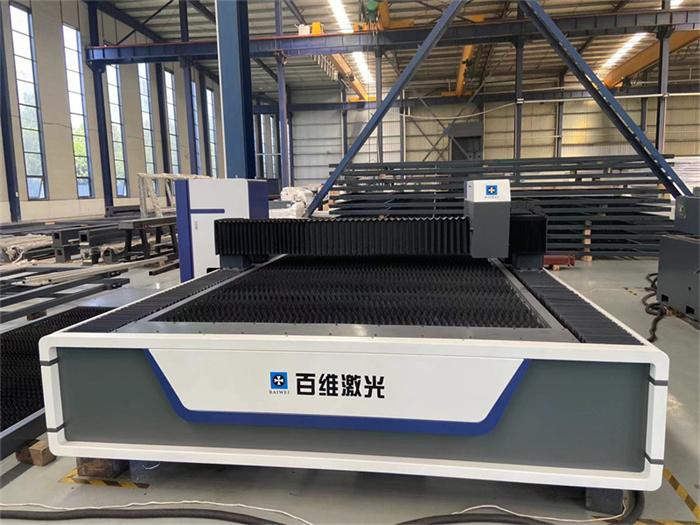

Laser cutting machines for the shipbuilding industry

No need to open the mold, just make the drawing on the computer, and the product can come out immediately, which can quickly develop new products and save costs.Model:BW-12025

Laser Power:500w/1kw/2kw/4kw/6kw/8kw/10kw/12kw

Max.moving Speed:120m/min

Max.cutting Speed:60m/min

Positioning accuracy:0.03mm

Re-position accuracy:0.02mm

Min.line Width:0.1mm

The laser cutting machine adopts a closed processing environment, which isolates the production, prevents the emission of smoke, and is safe and environmentally friendly. Baiwei production process

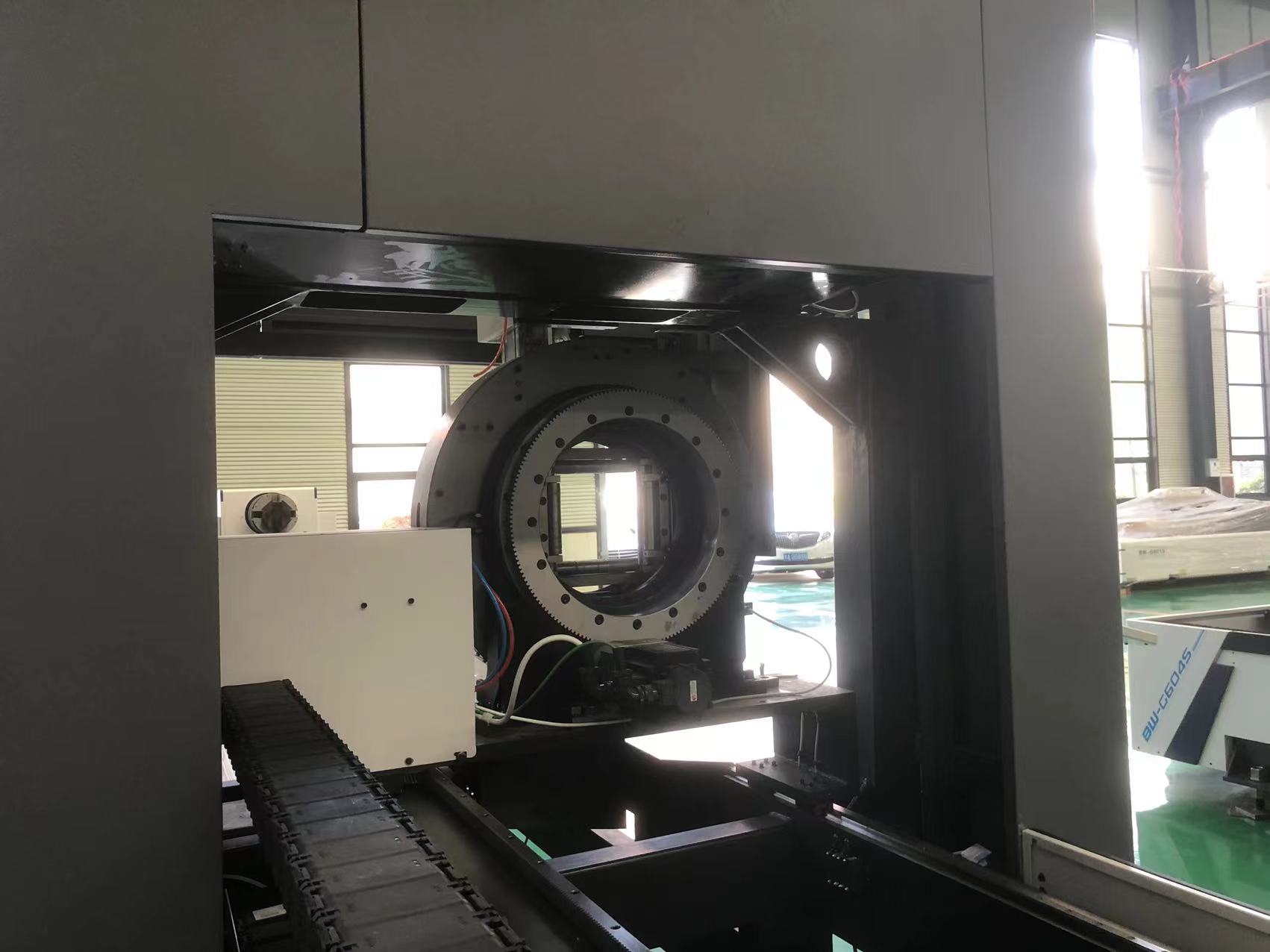

Baiwei’s exquisite processing technology has reached the world’s leading level. Each machine goes through 12 processes, including blanking, rough machining, welding, quenching, punching, painting, assembly to commissioning and testing, to ensure that the cutting accuracy reaches 0.01 before leaving the factory. mm. Each process has undergone strict quality control and inspection, and truly solve the worries from the source.In the field of shipbuilding, the marine steel plate cut by laser has good kerf quality, good verticality of the notch surface, no slag, thin oxide layer, smooth surface, no need for secondary processing, can be directly welded, and has small thermal deformation, curve cutting High precision, reduce working hours, and achieve barrier-free cutting of high-strength ship plates.