In the process of laser processing the whole plate, due to the difference in material and cutting environment, the phenomenon of poor processing in local areas often occurs. Under normal circumstances, the staff will greatly affect the entire production progress in order to deal with local failures, thus affecting the laser processing. efficiency. In response to such a problem, a trial cutting and then mass production process is required before being mass-produced during the production process. Therefore, the cutting process of Baiwei Laser came into being.

.jpg)

Baiwei's cutting process is divided into two processes: trial knife and mass production. The test knife generally chooses a circle for cutting. Generally, there are no strict requirements for the size of the circle. However, it is necessary to determine the actual size and the size deviation after cutting, so that the size can be compensated in mass production. The main purpose is to check whether the parameters can be Normal cutting, whether the cutting section and cutting size are qualified, it is recommended to select the test knife pattern to test the knife.

Baiwei's

laser cutting machine does not require staff supervision during the cutting process. After the cutting is completed, the machine will automatically send a signal to remind the staff to replace the plate, thereby saving labor and material costs. During tool testing, the machine will automatically compensate for the dimensional deviation into the mass-produced graphics, and more intelligently complete the batch sheet processing process.

At the same time, according to the difference in thickness, processing width and processing responsibility of the plate, there are strict dimensional requirements and stable parameters before mass production. The processed workpiece is of high quality and practicability. processing effect.

In mass production, setting micro-connections on the cutting workpiece can effectively avoid the workpiece lifting due to the thermal deformation of the plate during the whole plate cutting process, and avoid parts flipping, collision, cutting dislocation, etc., thereby improving the smoothness of the entire plate cutting.

The sheet metal cutting technology of

Baiwei Laser has well solved the problem of sheet waste in the process of batch sheet metal processing. It is suitable for batch large-scale automated production, optimizes the entire production process, and greatly improves the production efficiency of laser sheet metal processing.

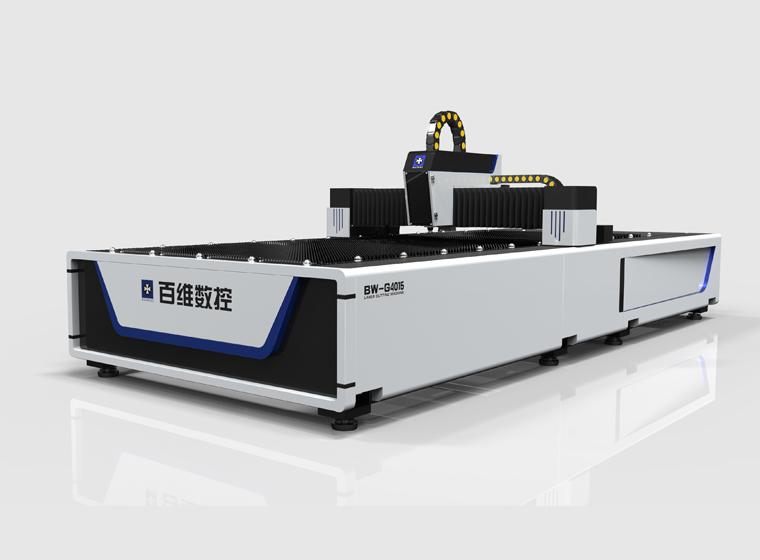

BW-G3015 3kw open type fiber laser cutting machine

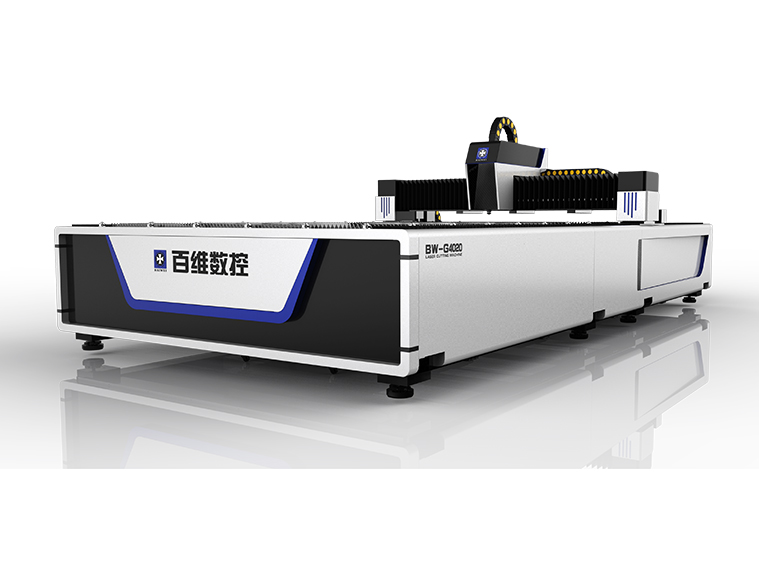

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

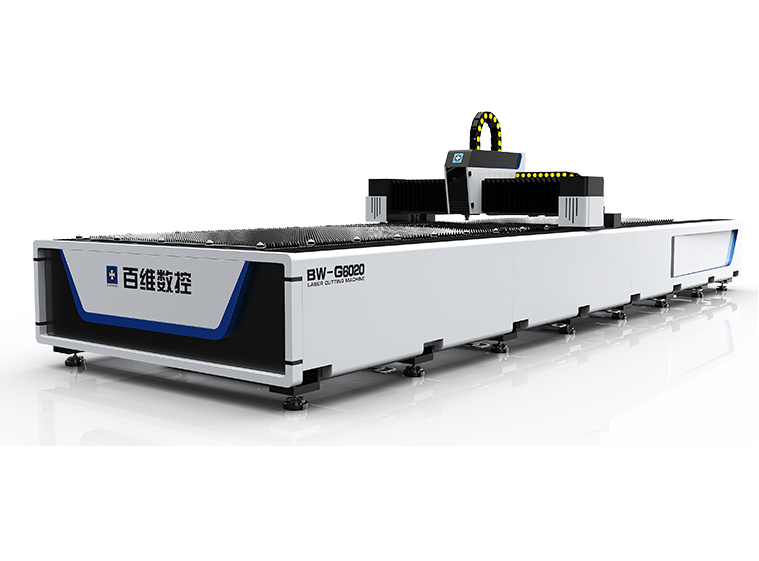

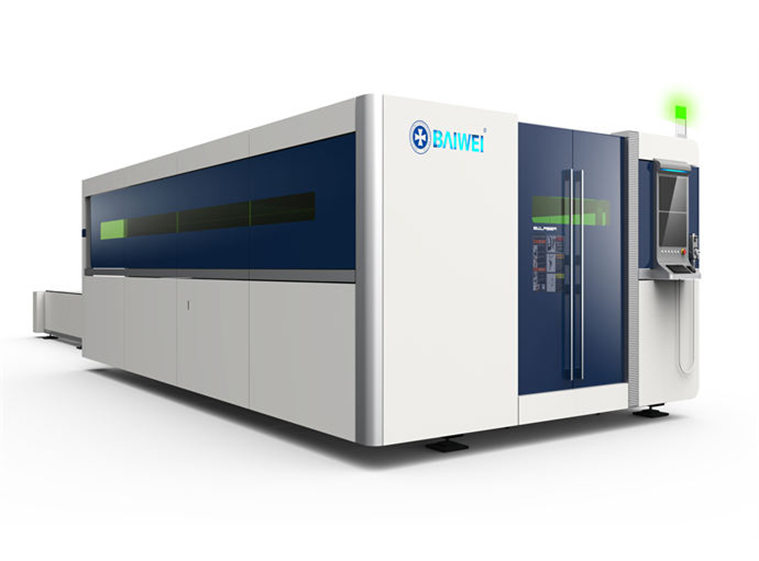

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

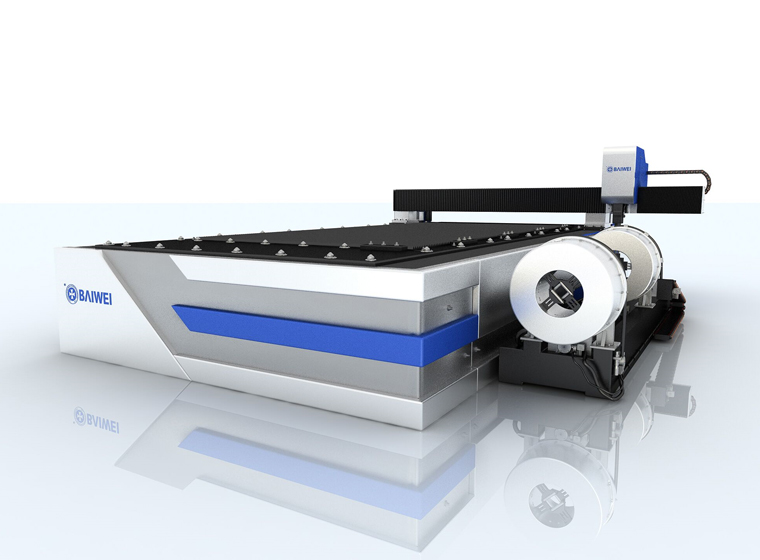

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

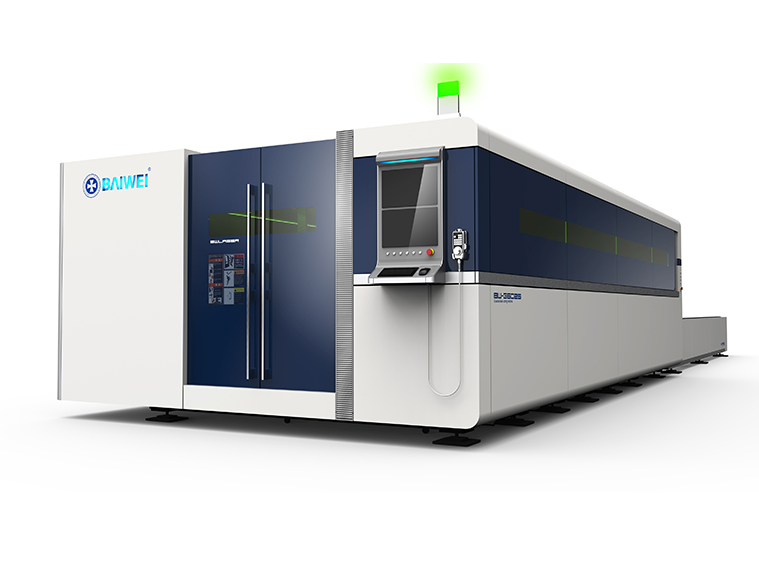

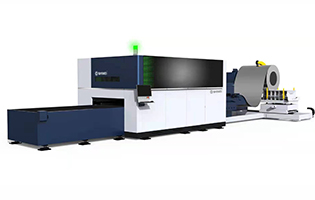

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

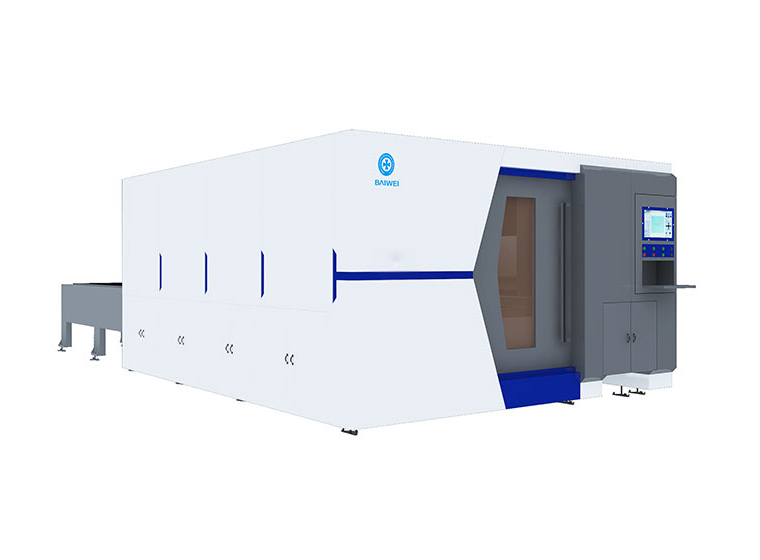

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

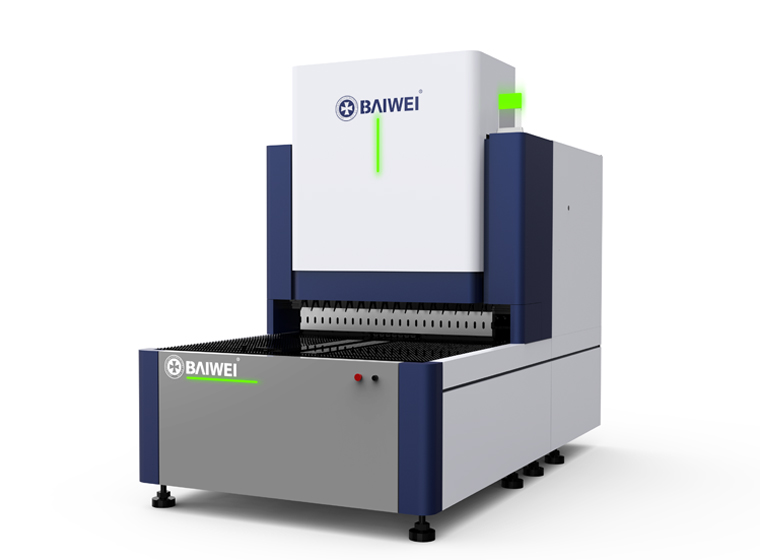

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)

.jpg)