How to choose auxiliary gas for fiber laser cutting machine?

The most widely used auxiliary gases that can be used by fiber laser cutting machine are mainly air, nitrogen, oxygen and argon. Now I will show you how to use them in different materials.

A.Air

Air can be supplied directly by air compressor. So it’s much cheaper compared to other gases. Although air contains about 20% oxygen, but it’s cutting efficiency is far less than oxygen. Air cutting capacity is similar to nitrogen.

It’s widely used for carbon steel, stainless steel, aluminum, aluminum alloy, copper, brass etc. But if you have high requirements for cutting quality, we do not suggest use air to cut stainless steel, copper, brass, aluminum, aluminum alloy etc cause the air will oxidize the base metal.

B.Nitrogen

It’s widely used in stainless steel, copper, brass, aluminum, aluminum alloy,galvanized sheet etc.

C.Oxygen

It’s widely used in carbon steel etc

3.Argon

The cost of argon is much expensive, it’s widely used for Titanium, Titanium Alloy.

Why we do not recommend you choose second-hand fiber laser cutting machine?

a.The laser source is the core part of fiber laser cutting machine, the cost of the laser source is expensive; For a second hand fiber laser cutting machine, the using life of laser source is reduced, so it will reduce the cutting efficiency. In future,you will spend more money to purchase a new laser source;

b.The function of CNC machine tools are updated quickly, while the function of second-hand equipment are backward, which is not conducive to the fine processing in future.

c.With bad after-sale service support, it’s hardly to get the service from the original factory when you need support;

d.Incomplete accessories will affect the cutting progress and increase the using cost.

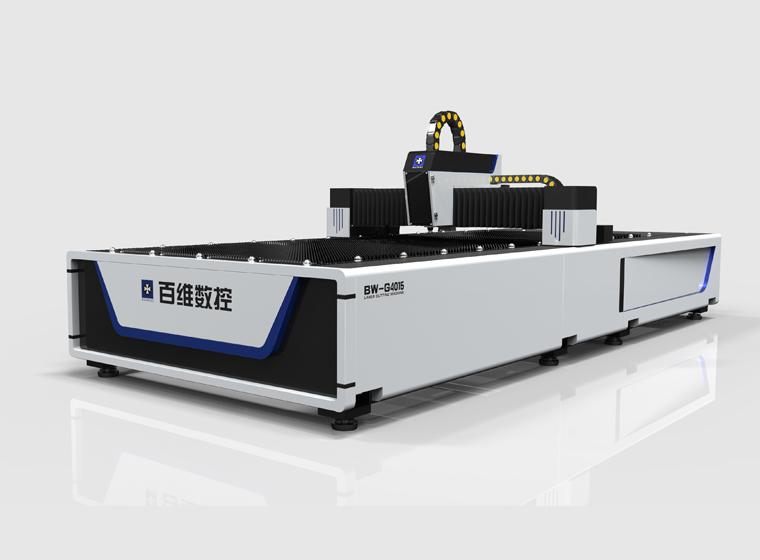

BW-G3015 3kw open type fiber laser cutting machine

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

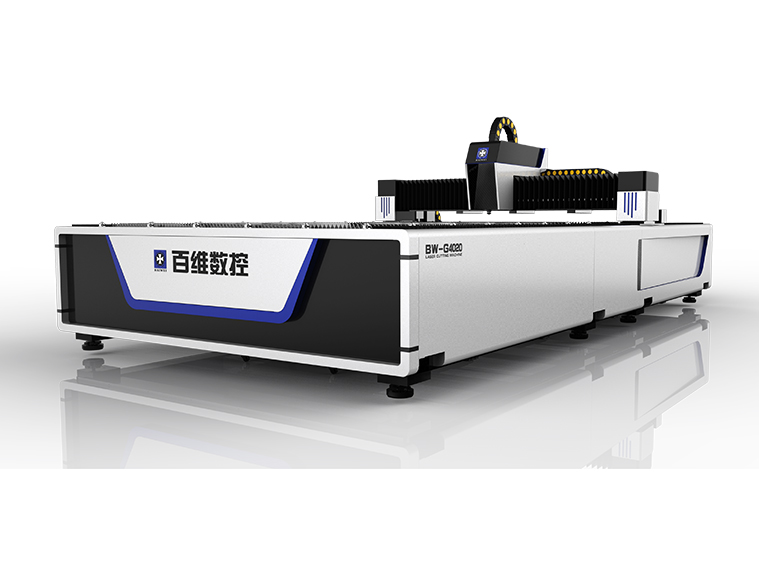

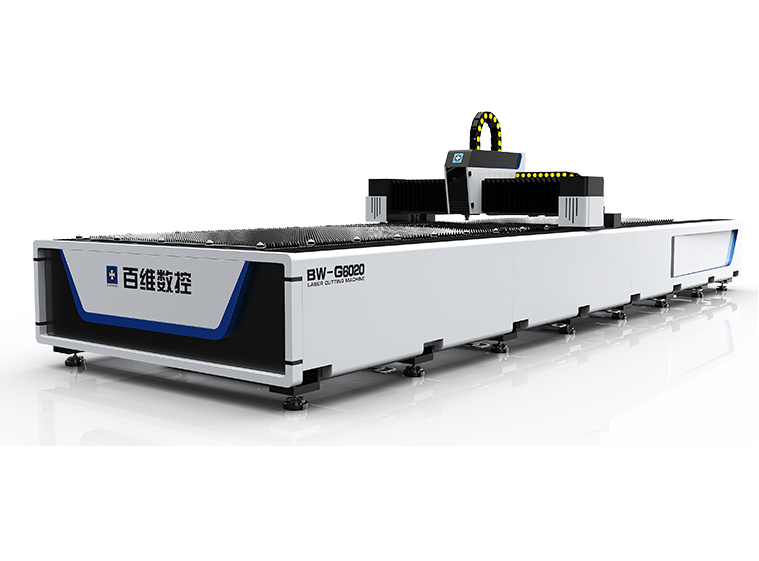

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

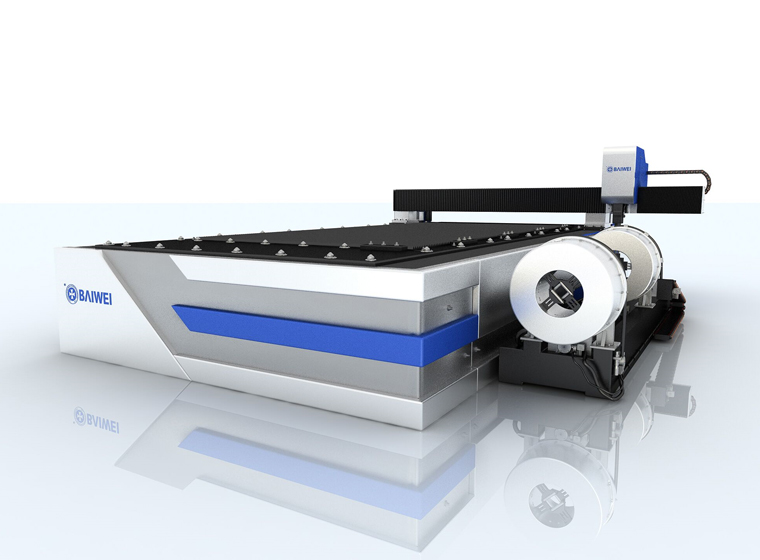

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

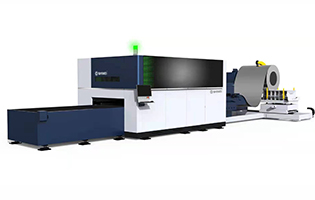

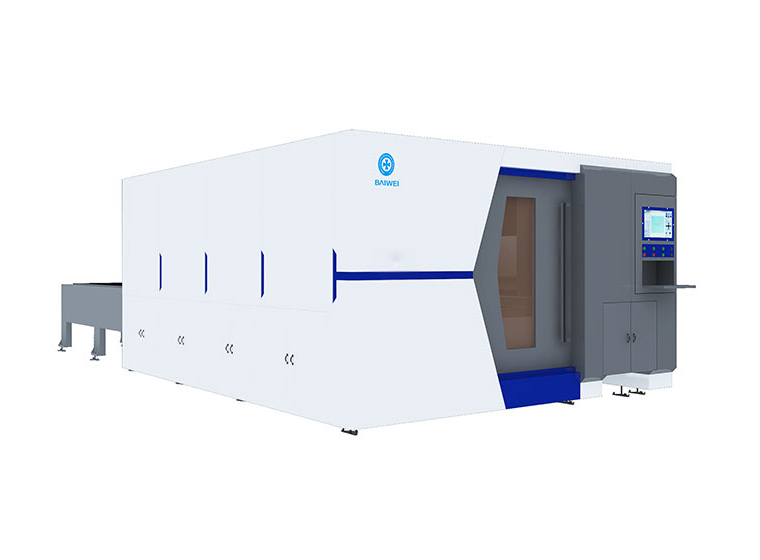

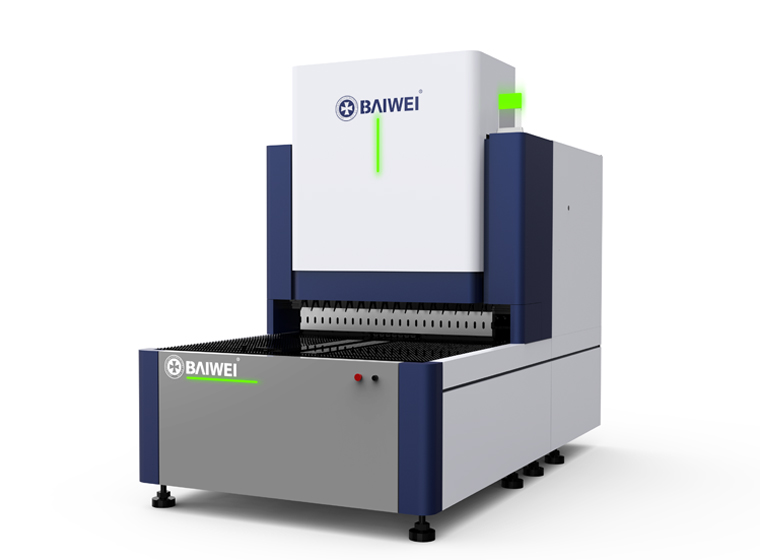

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

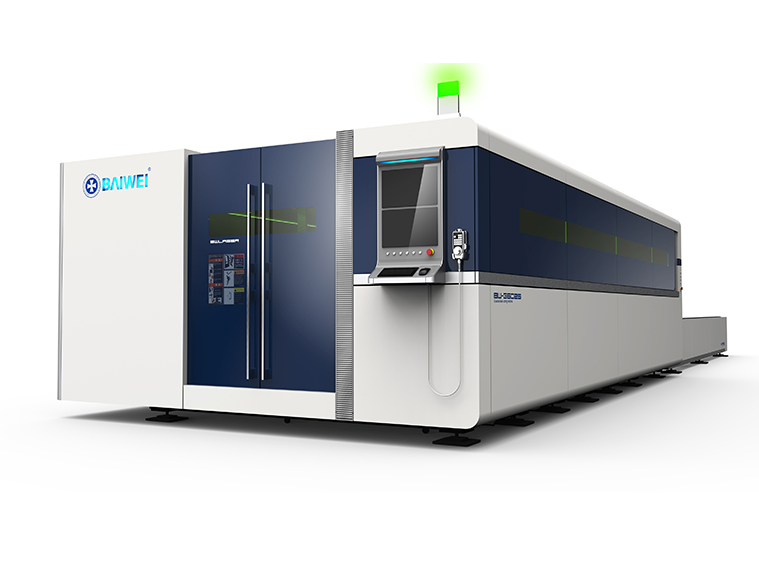

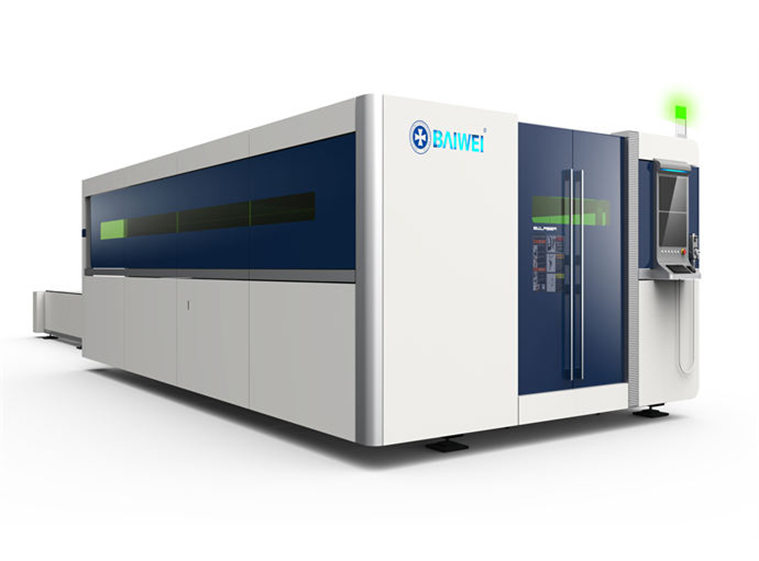

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)