Cooperation field

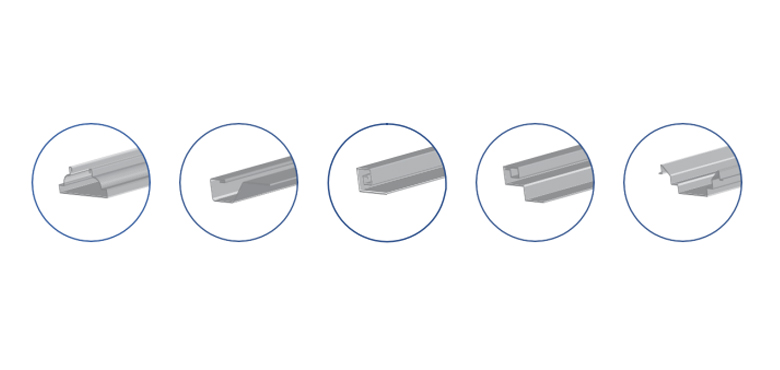

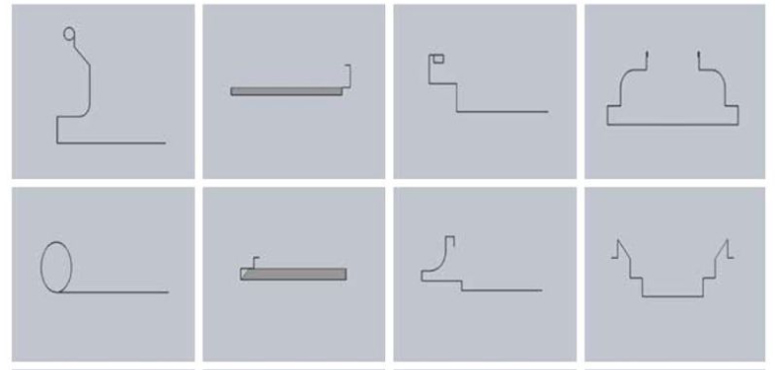

BaiweiI intelligent flexible bending center can be widely used in sheet metal bending of various types of metal sheets, including file cabinet bending, electrical cabinet bending, kitchen utensil bending, metal furniture bending, metal decorative bending, fire ventilation metal Bending of parts, bending of shells in refrigeration fields.

such as refrigerators, freezers and air conditioners, bending of elevator sheet metal, bending of auto parts, bending of metal doors and windows, etc...It can easily realize the bending

requirements of circular arc, dead edge, return type, closed type and other complex types of

sheet metal.

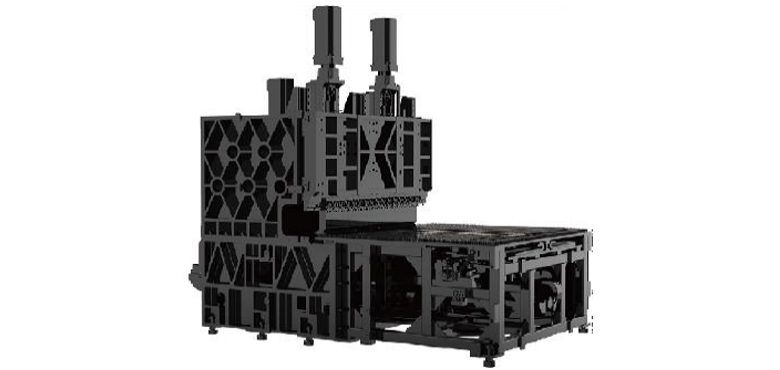

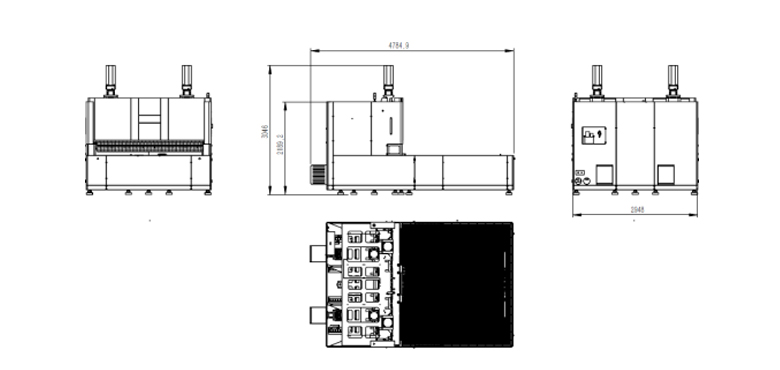

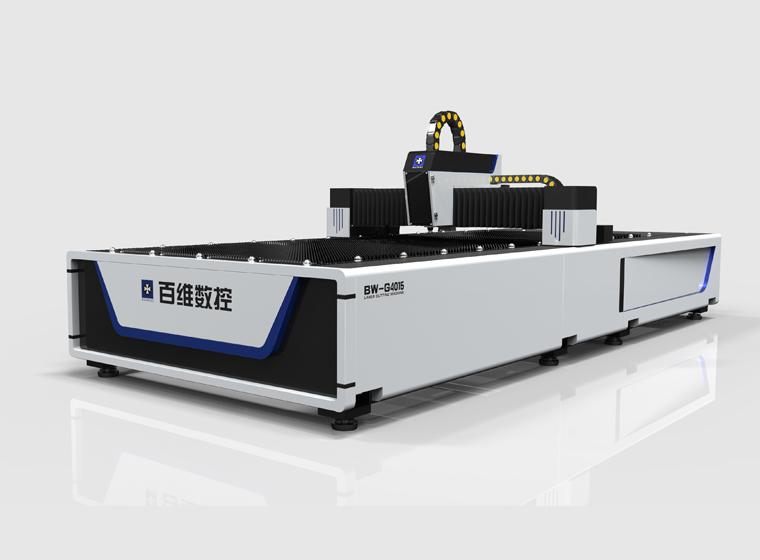

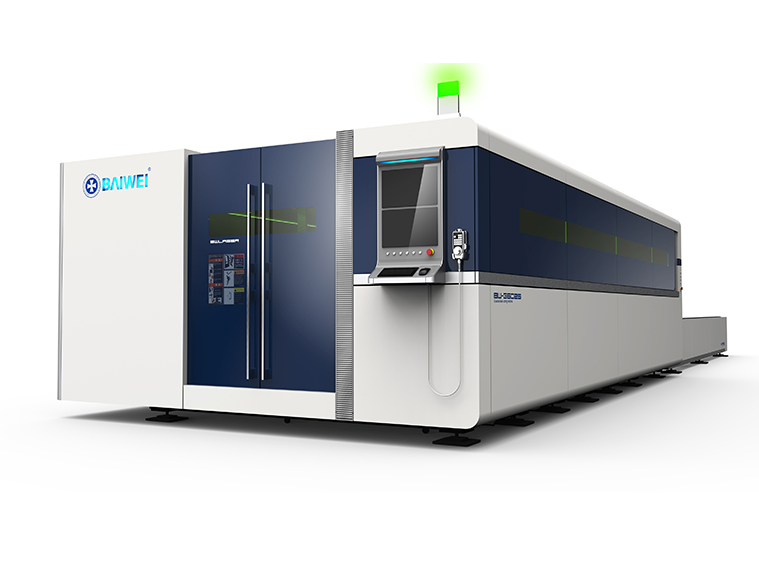

BW-G3015 3kw open type fiber laser cutting machine

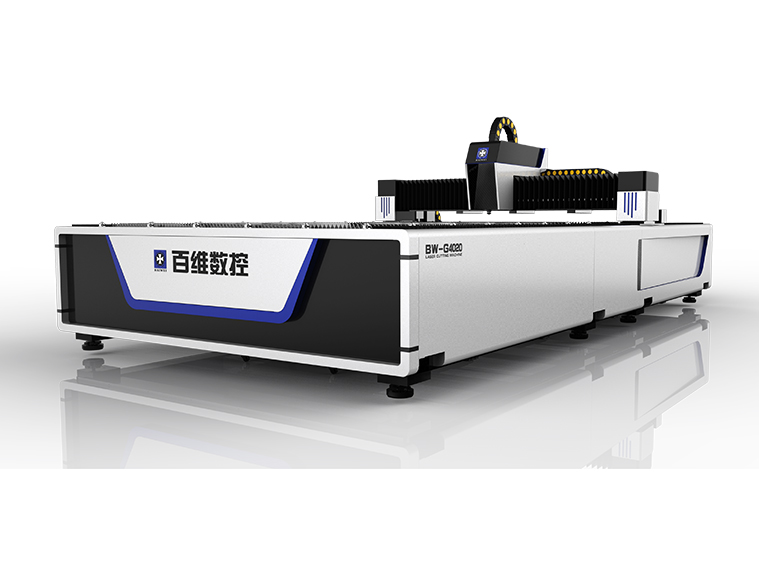

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

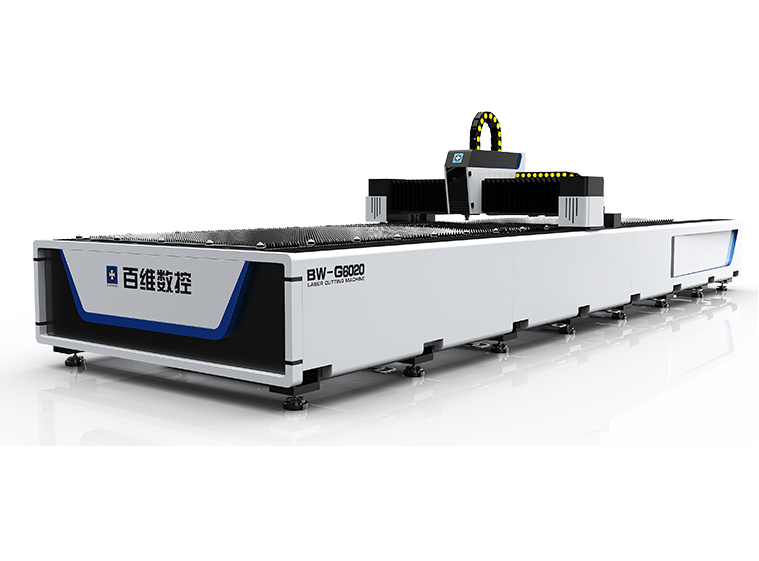

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

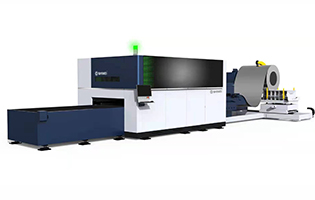

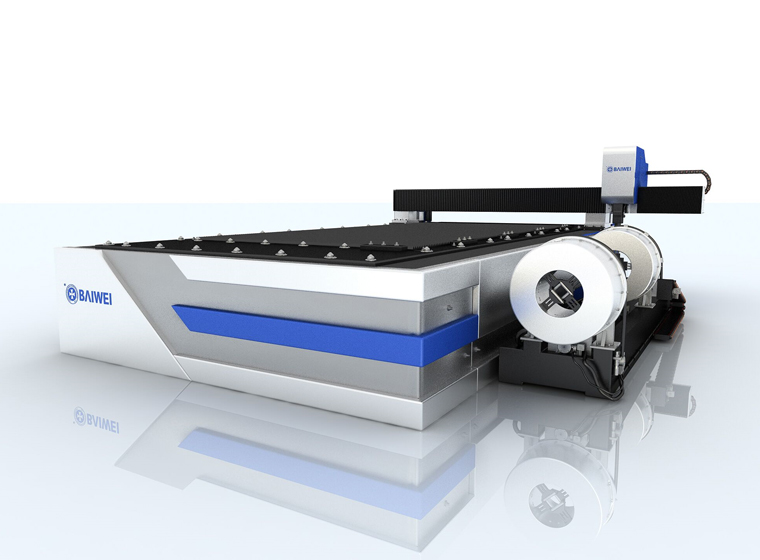

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

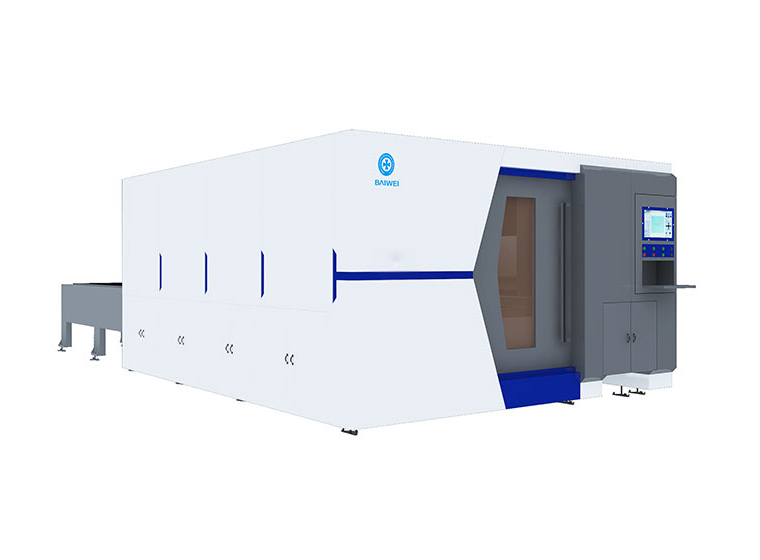

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

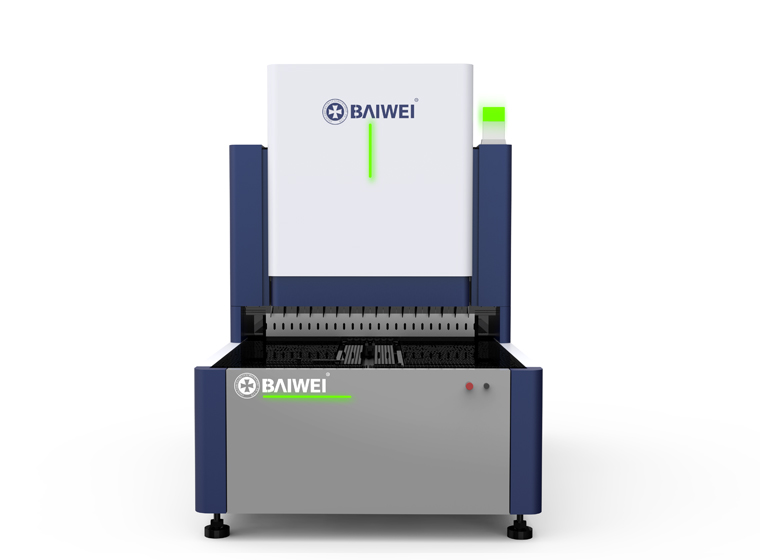

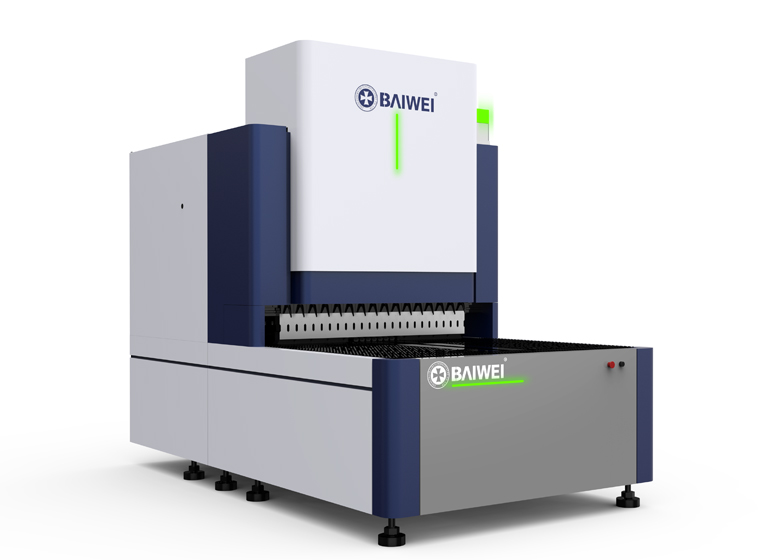

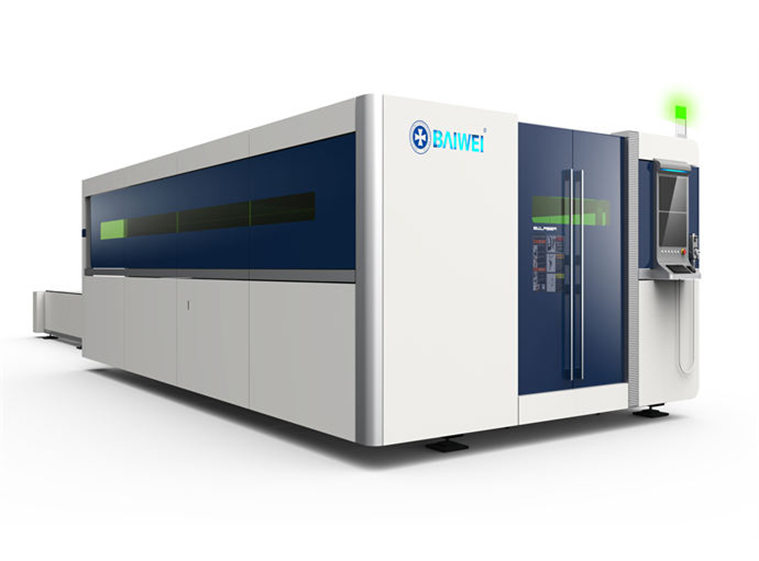

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

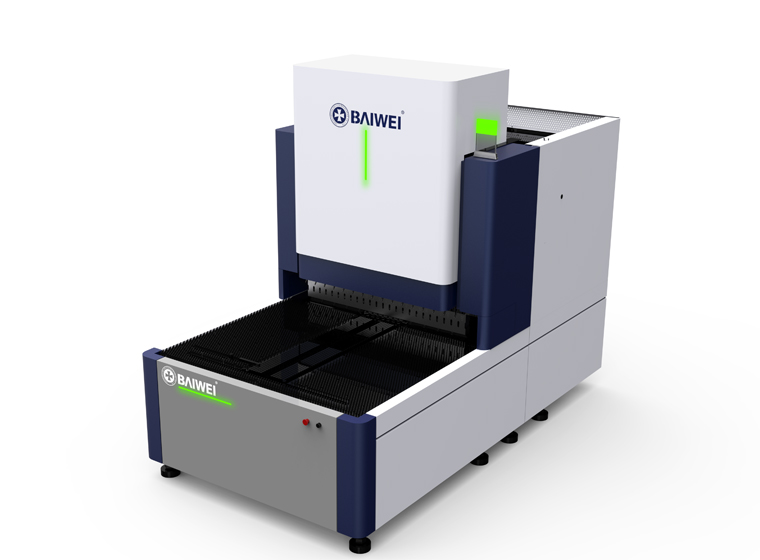

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

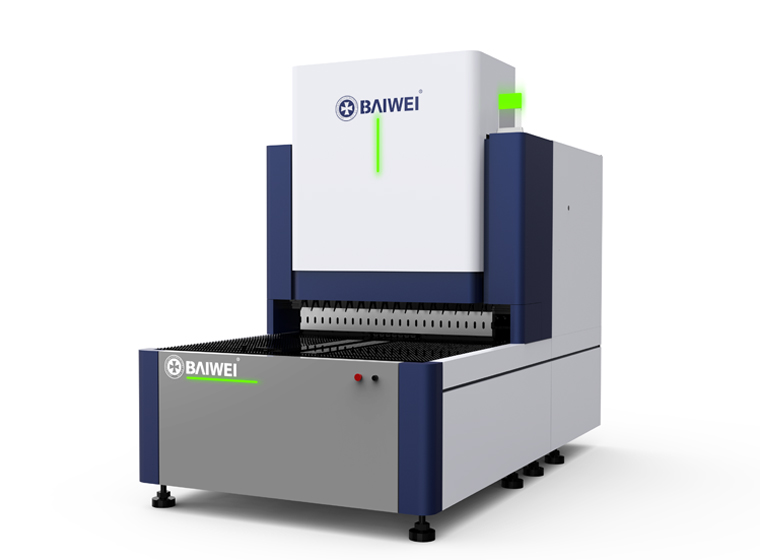

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)