A

pipe laser cutting machine mainly refers to the metal pipe cutting equipment manufactured by fiber lasers, which is a kind of fiber laser cutting machine, also known as a professional laser pipe cutting machine. Pipe laser cutting machine is a new type of laser cutting machine product newly invented in the international market in recent years. This laser cutting machine product has advantages in cutting speed and mechanical volume. Today we mainly come to Talk about the principle of this laser cutting machine and what the main advantages and performances are.

Principle of tube laser cutting machine: Tube laser cutting is realized by the application of high power density energy generated by laser focusing. Under the control of the computer, the laser is discharged through pulses, so as to output a controlled repetitive high-frequency pulsed laser to form a beam of a certain frequency and a certain pulse width. On the surface, tiny, high-energy-density light spots are formed, and the focal spots are located near the surface to be processed, melting or vaporizing the processed material at an instant high temperature. The high-energy laser pulse sputters a small hole on the surface of the object in an instant. Under the control of the computer, the cutting head of the stainless steel laser cutting machine and the material to be processed perform continuous relative motion according to the pre-drawn pattern, so that the object will be processed into desired shape.

Advantages of tube laser cutting machine: low cost, fully automatic, easy to operate 1. Fast laser processing speed 3. The laser processing is automatically controlled by the computer, and there is no need for manual intervention during production.

Laser processing is flexible and easy to change. According to the orders of different customers, you only need to draw the processing diagram on the computer, and the product can be produced immediately, which saves the cost of conventional mold opening and effectively avoids the differentiation of the same product. production, reducing the risk of product backlog.

Applicable materials for

pipe laser cutting machine: stainless steel, carbon steel, alloy steel, spring steel, aluminum, copper and other metal pipes, which have excellent processing effect on various high-hard and brittle alloy materials.

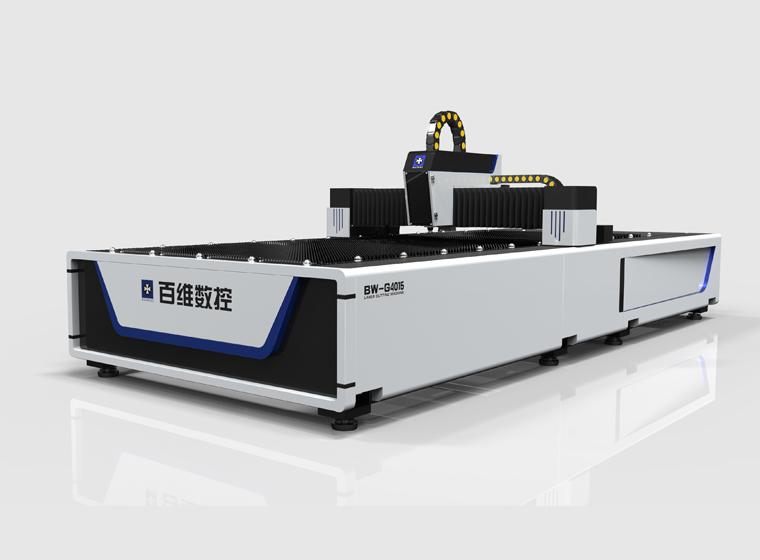

BW-G3015 3kw open type fiber laser cutting machine

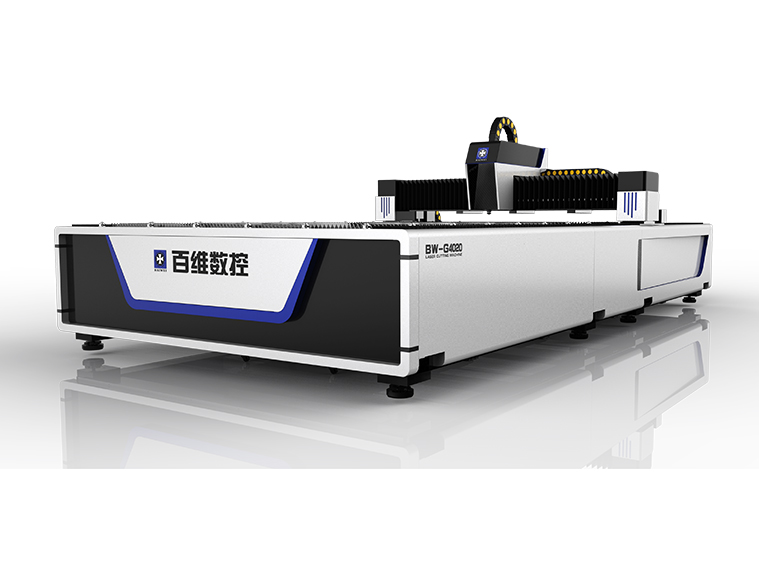

BW-G3015 3kw open type fiber laser cutting machine BW-G4020 Open type fiber laser cutting machine

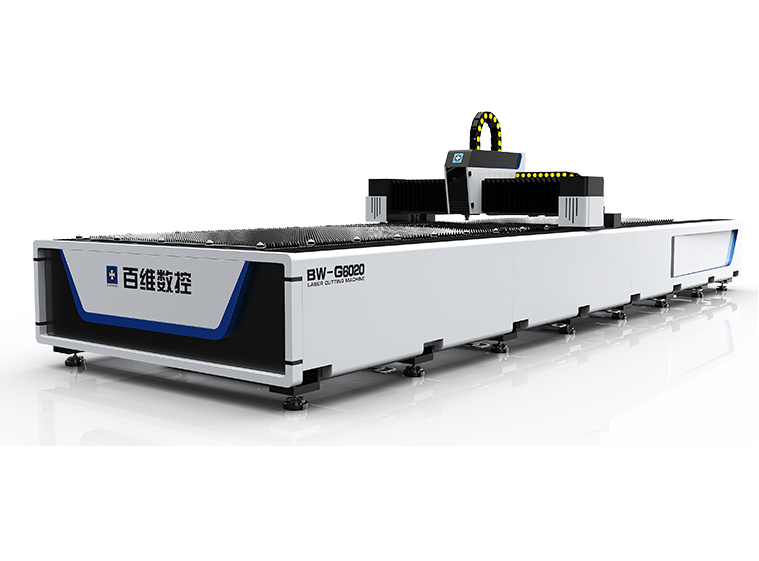

BW-G4020 Open type fiber laser cutting machine BW-G6020 Open type fiber laser cutting machine

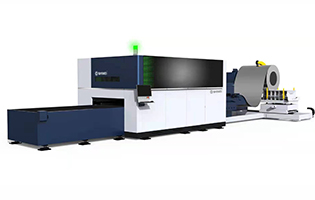

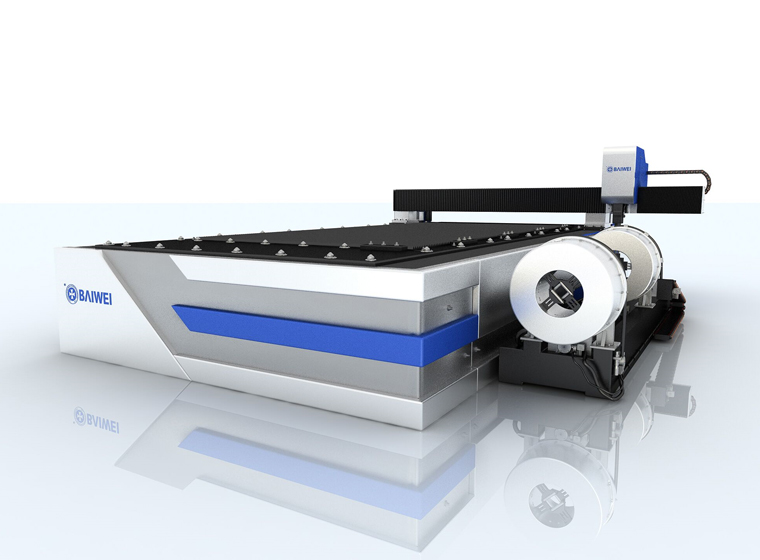

BW-G6020 Open type fiber laser cutting machine BW3000 6kw open type fiber laser plate&tube cutting machine

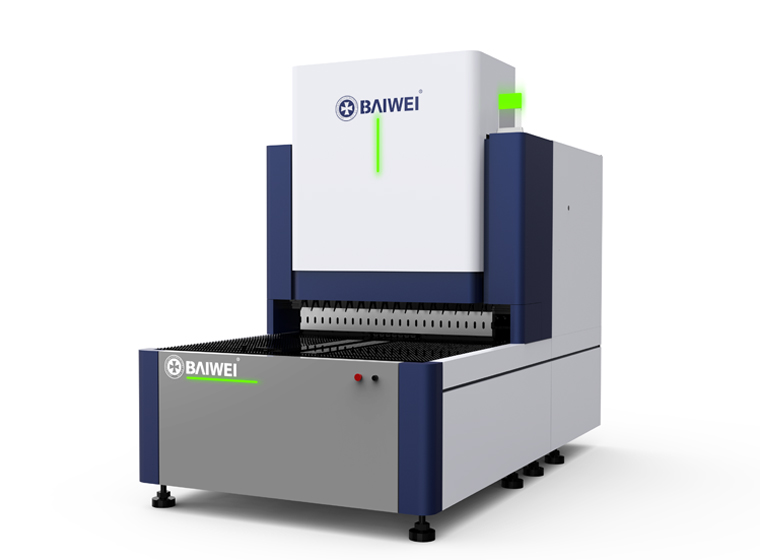

BW3000 6kw open type fiber laser plate&tube cutting machine BW3000 6KW closed type fiber laser plate&tube cutting machine

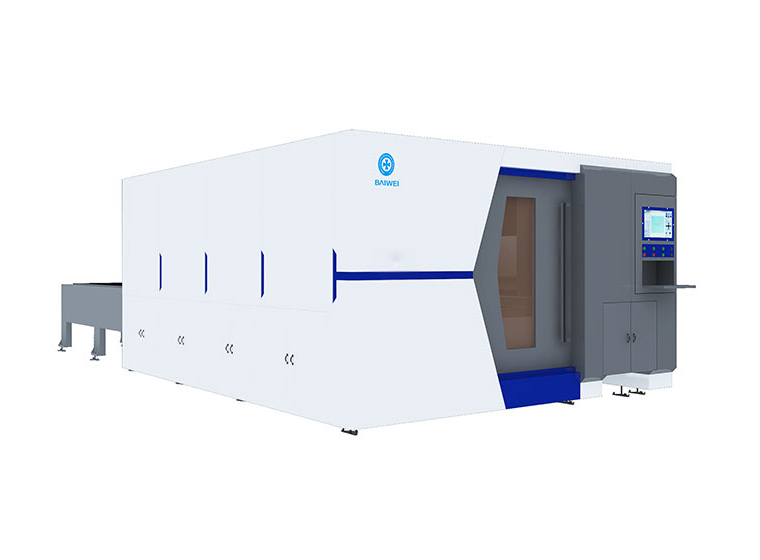

BW3000 6KW closed type fiber laser plate&tube cutting machine BW-G6025 Closed type fiber laser cutting machine

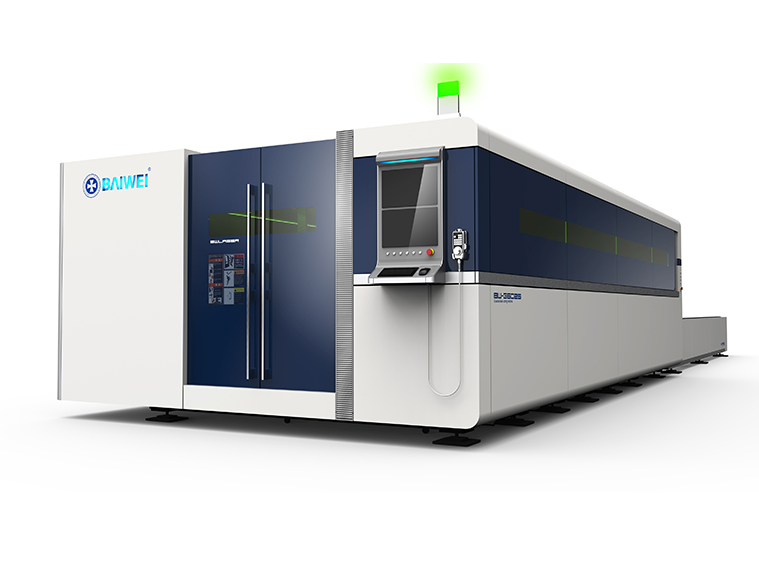

BW-G6025 Closed type fiber laser cutting machine BW-G12025 Closed type metal sheet laser cutting machine machine

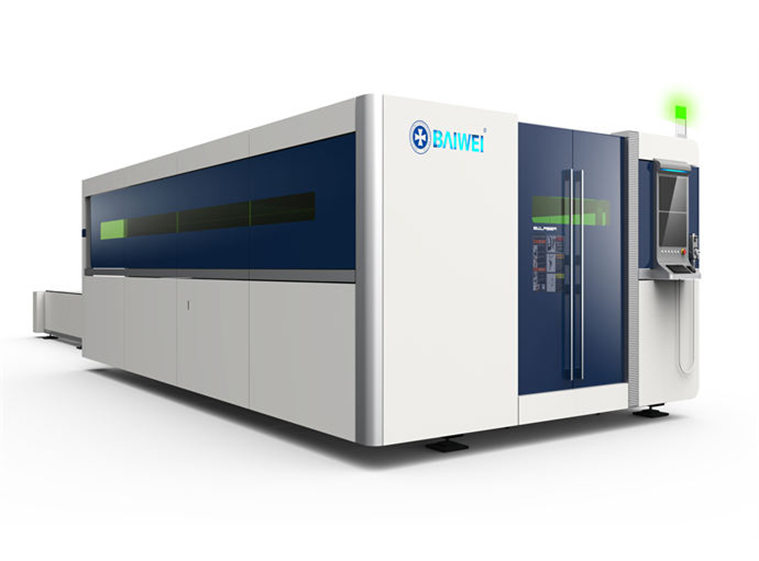

BW-G12025 Closed type metal sheet laser cutting machine machine.jpg) BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

BWQG SERIES Professional Laser Tube Cutting Machine 3kw-20kw

.jpg)

.jpg)